Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

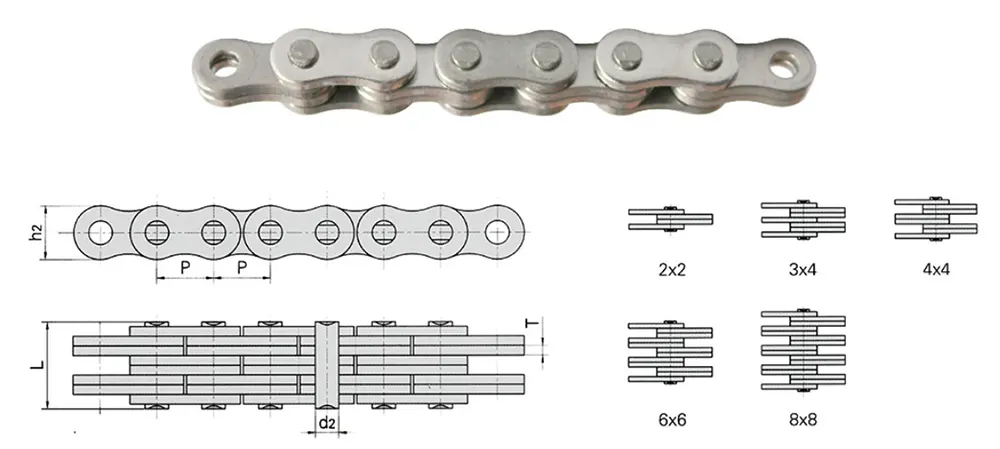

The LH2844SS/BL1444SS Stainless Steel Leaf Chain is characterized by the following parameters:

| Chain No. | Pitch | Lacing | Plate thickness | Plate depth | Pin diameter | Pin length | Breaking load | Average tensile strength | |

| ISO GB |

ANSI | P(mm) | T(mm) | h2(mm) | d2(mm) | L(mm) | Q min(KN) |

Q0(KN) | |

| LH2022SS | BL1022SS | 31.75 | 2x2 | 4.9 | 30.1 | 11.1 | 25.1 | 80.962 | 103.11 |

| LH2023SS | BL1023SS | 31.75 | 2x3 | 4.9 | 30.1 | 11.1 | 30 | 80.962 | 103.11 |

| LH2034SS | BL1034SS | 31.75 | 3x4 | 4.9 | 30.1 | 11.1 | 40.2 | 127.911 | 162.33 |

| LH2044SS | BL1044SS | 31.75 | 4x4 | 4.9 | 30.1 | 11.1 | 45.2 | 161.91 | 204.33 |

| LH2046SS | BL1046SS | 31.75 | 4x6 | 4.9 | 30.1 | 11.1 | 55 | 161.91 | 204.33 |

| LH2066SS | BL1066SS | 31.75 | 6x6 | 4.9 | 30.1 | 11.1 | 65 | 242.865 | 301 |

| LH2088SS | BL1088SS | 31.75 | 8x8 | 4.9 | 30.1 | 11.1 | 84.8 | 323.82 | 388.43 |

| LH2422SS | BL1222SS | 38.1 | 2x2 | 5.6 | 36 | 12.7 | 28 | 105.868 | 134.61 |

| LH2423SS | BL1223SS | 38.1 | 2x3 | 5.6 | 36 | 12.7 | 33.7 | 105.868 | 134.61 |

| LH2434SS | BL1234SS | 38.1 | 3x4 | 5.6 | 36 | 12.7 | 44.8 | 171.248 | 216.02 |

| LH2444SS | BL1244SS | 38.1 | 4x4 | 5.6 | 36 | 12.7 | 50.6 | 211.729 | 267.19 |

| LH2446SS | BL1246SS | 38.1 | 4x6 | 5.6 | 36 | 12.7 | 61.7 | 211.729 | 267.19 |

| LH2466SS | BL1266SS | 38.1 | 6x6 | 5.6 | 36 | 12.7 | 73.4 | 317.59 | 380.03 |

| LH2488SS | BL1288SS | 38.1 | 8x8 | 5.6 | 36 | 12.7 | 96 | 423.458 | 507.71 |

| LH2822SS | BL1422SS | 44.45 | 2x2 | 6.4 | 42 | 14.27 | 31.7 | 133.889 | 158.34 |

| LH2823SS | BL1423SS | 44.45 | 2x3 | 6.4 | 42 | 14.27 | 38.2 | 133.889 | 158.34 |

| LH2834SS | BL1434SS | 44.45 | 3x4 | 6.4 | 42 | 14.27 | 51.2 | 221.067 | 260.47 |

| LH2844SS | BL1444SS | 44.45 | 4x4 | 6.4 | 42 | 14.27 | 57.5 | 267.771 | 315.49 |

| LH2846SS | BL1446SS | 44.45 | 4x6 | 6.4 | 42 | 14.27 | 70.5 | 267.771 | 315.49 |

| LH2866SS | BL1466SS | 44.45 | 6x6 | 6.4 | 42 | 14.27 | 83.3 | 404.768 | 478.03 |

| LH2888SS | BL1488SS | 44.45 | 8x8 | 6.4 | 42 | 14.27 | 109.5 | 535.542 | 632.31 |

| LH3222SS | BL1622SS | 50.8 | 2x2 | 7.5 | 48 | 17.46 | 36.8 | 202.384 | 239.19 |

| LH3223SS | BL1623SS | 50.8 | 2x3 | 7.5 | 48 | 17.46 | 44.4 | 202.384 | 239.19 |

| LH3234SS | BL1634SS | 50.8 | 3x4 | 7.5 | 48 | 17.46 | 59.4 | 308.252 | 364 |

| LH3244SS | BL1644SS | 50.8 | 4x4 | 7.5 | 48 | 17.46 | 67 | 404.768 | 476.49 |

| LH3246SS | BL1646SS | 50.8 | 4x6 | 7.5 | 48 | 17.46 | 82.4 | 404.768 | 476.49 |

| LH3266SS | BL1666SS | 50.8 | 6x6 | 7.5 | 48 | 17.46 | 97.6 | 600.152 | 700 |

| LH3288SS | BL1688SS | 50.8 | 8x8 | 7.5 | 48 | 17.46 | 128.1 | 809.536 | 954.8 |

Introduction

This LH2844SS/BL1444SS Stainless Steel Leaf Chain is a high-quality, durable chain that is designed for use in a variety of applications. The chain is constructed from stainless steel material, which makes it resistant to corrosion and able to withstand harsh environments. The chain is also designed with a leaf design, which helps to provide maximum strength and flexibility.

Features

Stainless Steel Material

The chain is constructed from high-quality stainless steel material, which makes it resistant to corrosion and able to withstand harsh environments. This makes the chain ideal for use in applications where it will be exposed to moisture, chemicals, or other corrosive elements.

Leaf Design

The chain is designed with a leaf design, which helps to provide maximum strength and flexibility. The leaf design allows the chain to bend and flex without breaking, which makes it ideal for use in applications where the chain will be subjected to bending or twisting.

High-Quality Construction

The LH2844SS/BL1444SS Stainless Steel Leaf Chain is constructed with the highest quality materials and workmanship to ensure maximum durability and strength. The chain is designed to provide long-lasting performance, even in the most demanding applications.

Applications

Food Processing Industry

The LH2844SS/BL1444SS Stainless Steel Leaf Chain is ideal for use in the food processing industry. The chain's stainless steel construction makes it resistant to corrosion and able to withstand harsh cleaning agents, making it ideal for use in environments where hygiene is critical.

Chemical Processing Industry

The LH2844SS/BL1444SS Stainless Steel Leaf Chain is also well-suited for use in the chemical processing industry. The chain's resistance to corrosion and ability to withstand harsh environments make it ideal for use in applications where it will be exposed to chemicals or other corrosive elements.

Agricultural Industry

The LH2844SS/BL1444SS Stainless Steel Leaf Chain is also suitable for use in the agricultural industry. The chain's high-strength design makes it ideal for use in applications where it will be exposed to heavy loads or other stresses.

Maintenance

Cleaning

To ensure maximum performance and longevity, the LH2844SS/BL1444SS Stainless Steel Leaf Chain should be regularly cleaned and maintained. The chain can be cleaned using a mild detergent and a soft brush. After cleaning, the chain should be thoroughly rinsed with clean water and allowed to air-dry.

Lubrication

The LH2844SS/BL1444SS Stainless Steel Leaf Chain should also be lubricated regularly to ensure smooth operation. A high-quality lubricant should be used, and the chain should be lubricated according to the manufacturer's recommendations.

Conclusion

Overall, the LH2844SS/BL1444SS Stainless Steel Leaf Chain is a high-quality, durable chain that is designed to provide long-lasting performance in a variety of industrial applications. The chain's stainless steel construction, leaf design, and high-quality construction make it ideal for use in food processing, chemical processing, agricultural, and other demanding applications. With proper maintenance and care, the LH2844SS/BL1444SS Stainless Steel Leaf Chain will provide reliable, long-lasting performance for many years to come.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We offer a wide range of high-quality stainless steel roller chains, including the LH2844SS/BL1444SS Stainless Steel Leaf Chain. Our products are known for their exceptional quality, durability, and strength.

Our stainless steel roller chains are made from the finest materials and are designed to withstand the toughest conditions. They are resistant to corrosion, heat, and wear, making them ideal for use in a variety of industries, including food and beverage, pharmaceuticals, and chemical processing.

In addition to our LH2844SS/BL1444SS Stainless Steel Leaf Chain, we offer various other types of stainless steel roller chains, each designed to meet the unique needs of our customers. Our goal is to provide our customers with the very best products and services.

At RP Techniek BV, we are committed to excellence in everything we do. We take pride in our ability to deliver high-quality products and exceptional customer service. Our team of experts is dedicated to providing our customers with the best possible experience, from product selection to delivery.

We are proud of our production capabilities and are always striving to improve our processes to better meet the needs of our customers. Our state-of-the-art facilities allow us to produce high-quality stainless steel roller chains quickly and efficiently, ensuring that our customers receive their orders on time and to their exact specifications.

Choose RP Techniek BV for all your stainless steel roller chain needs. Contact us today to learn more about our products and services.

Sprockets for Sale

The LH2844SS/BL1444SS Stainless Steel Leaf Chain is perfectly complemented by our wide range of matching sprockets. At our company, we offer a diverse selection of sprockets to meet your specific needs.

Our sprockets are designed with precision and durability in mind, ensuring they can withstand the demanding conditions of various industries. Whether you require sprockets for heavy-duty applications or more lightweight operations, we have the right solution for you.

Our extensive inventory includes sprockets of different sizes, tooth profiles, and materials. We understand that each application has unique requirements, and our goal is to provide you with the perfect sprocket that ensures smooth operation and maximum efficiency.

With our high-quality sprockets, you can rely on enhanced performance, reduced wear and tear, and extended chain life. We are committed to offering reliable products that meet the highest standards of quality and performance.

For further inquiries or to explore our complete range of sprockets for sale, please visit our website or contact our sales team.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...