Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

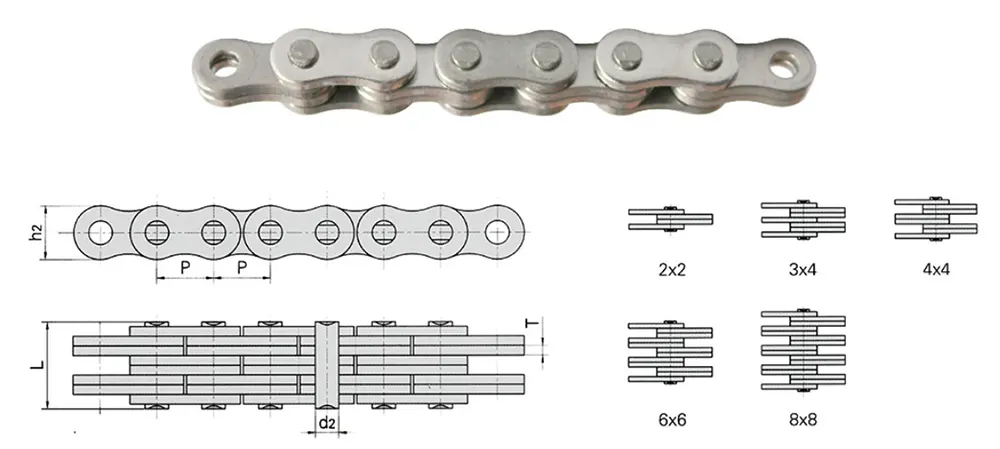

The LH2444SS/BL1244SS Stainless Steel Leaf Chain has the following parameters:

| Chain No. | Pitch | Lacing | Plate thickness | Plate depth | Pin diameter | Pin length | Breaking load | Average tensile strength | |

| ISO GB |

ANSI | P(mm) | T(mm) | h2(mm) | d2(mm) | L(mm) | Q min(KN) |

Q0(KN) | |

| LH2022SS | BL1022SS | 31.75 | 2x2 | 4.9 | 30.1 | 11.1 | 25.1 | 80.962 | 103.11 |

| LH2023SS | BL1023SS | 31.75 | 2x3 | 4.9 | 30.1 | 11.1 | 30 | 80.962 | 103.11 |

| LH2034SS | BL1034SS | 31.75 | 3x4 | 4.9 | 30.1 | 11.1 | 40.2 | 127.911 | 162.33 |

| LH2044SS | BL1044SS | 31.75 | 4x4 | 4.9 | 30.1 | 11.1 | 45.2 | 161.91 | 204.33 |

| LH2046SS | BL1046SS | 31.75 | 4x6 | 4.9 | 30.1 | 11.1 | 55 | 161.91 | 204.33 |

| LH2066SS | BL1066SS | 31.75 | 6x6 | 4.9 | 30.1 | 11.1 | 65 | 242.865 | 301 |

| LH2088SS | BL1088SS | 31.75 | 8x8 | 4.9 | 30.1 | 11.1 | 84.8 | 323.82 | 388.43 |

| LH2422SS | BL1222SS | 38.1 | 2x2 | 5.6 | 36 | 12.7 | 28 | 105.868 | 134.61 |

| LH2423SS | BL1223SS | 38.1 | 2x3 | 5.6 | 36 | 12.7 | 33.7 | 105.868 | 134.61 |

| LH2434SS | BL1234SS | 38.1 | 3x4 | 5.6 | 36 | 12.7 | 44.8 | 171.248 | 216.02 |

| LH2444SS | BL1244SS | 38.1 | 4x4 | 5.6 | 36 | 12.7 | 50.6 | 211.729 | 267.19 |

| LH2446SS | BL1246SS | 38.1 | 4x6 | 5.6 | 36 | 12.7 | 61.7 | 211.729 | 267.19 |

| LH2466SS | BL1266SS | 38.1 | 6x6 | 5.6 | 36 | 12.7 | 73.4 | 317.59 | 380.03 |

| LH2488SS | BL1288SS | 38.1 | 8x8 | 5.6 | 36 | 12.7 | 96 | 423.458 | 507.71 |

| LH2822SS | BL1422SS | 44.45 | 2x2 | 6.4 | 42 | 14.27 | 31.7 | 133.889 | 158.34 |

| LH2823SS | BL1423SS | 44.45 | 2x3 | 6.4 | 42 | 14.27 | 38.2 | 133.889 | 158.34 |

| LH2834SS | BL1434SS | 44.45 | 3x4 | 6.4 | 42 | 14.27 | 51.2 | 221.067 | 260.47 |

| LH2844SS | BL1444SS | 44.45 | 4x4 | 6.4 | 42 | 14.27 | 57.5 | 267.771 | 315.49 |

| LH2846SS | BL1446SS | 44.45 | 4x6 | 6.4 | 42 | 14.27 | 70.5 | 267.771 | 315.49 |

| LH2866SS | BL1466SS | 44.45 | 6x6 | 6.4 | 42 | 14.27 | 83.3 | 404.768 | 478.03 |

| LH2888SS | BL1488SS | 44.45 | 8x8 | 6.4 | 42 | 14.27 | 109.5 | 535.542 | 632.31 |

| LH3222SS | BL1622SS | 50.8 | 2x2 | 7.5 | 48 | 17.46 | 36.8 | 202.384 | 239.19 |

| LH3223SS | BL1623SS | 50.8 | 2x3 | 7.5 | 48 | 17.46 | 44.4 | 202.384 | 239.19 |

| LH3234SS | BL1634SS | 50.8 | 3x4 | 7.5 | 48 | 17.46 | 59.4 | 308.252 | 364 |

| LH3244SS | BL1644SS | 50.8 | 4x4 | 7.5 | 48 | 17.46 | 67 | 404.768 | 476.49 |

| LH3246SS | BL1646SS | 50.8 | 4x6 | 7.5 | 48 | 17.46 | 82.4 | 404.768 | 476.49 |

| LH3266SS | BL1666SS | 50.8 | 6x6 | 7.5 | 48 | 17.46 | 97.6 | 600.152 | 700 |

| LH3288SS | BL1688SS | 50.8 | 8x8 | 7.5 | 48 | 17.46 | 128.1 | 809.536 | 954.8 |

1. What is LH2444SS/BL1244SS Stainless Steel Leaf Chain?

The LH2444SS/BL1244SS Stainless Steel Leaf Chain is a high-quality chain designed specifically for heavy-duty applications that require excellent corrosion resistance and durability. This chain is made from stainless steel, which offers superior strength and resistance to rust and other environmental factors.

2. Key Features of LH2444SS/BL1244SS Stainless Steel Leaf Chain

2.1 Superior Corrosion Resistance

The LH2444SS/BL1244SS Stainless Steel Leaf Chain is highly resistant to corrosion, making it suitable for use in harsh environments such as marine or chemical industry applications.

2.2 High Strength and Load Capacity

With its robust construction and high-quality stainless steel material, this chain has excellent strength and load-carrying capacity, ensuring reliable performance even under heavy loads.

2.3 Smooth Operation

The LH2444SS/BL1244SS Stainless Steel Leaf Chain is designed to provide smooth and precise operation, minimizing friction and wear, which extends the chain's service life and reduces maintenance requirements.

2.4 Easy Installation and Maintenance

Featuring a user-friendly design, this chain is easy to install and maintain. Its stainless steel construction reduces the need for frequent lubrication and allows for hassle-free cleaning.

3. Applications of LH2444SS/BL1244SS Stainless Steel Leaf Chain

The LH2444SS/BL1244SS Stainless Steel Leaf Chain finds its application in various industries where corrosion resistance and durability are crucial. Some common applications include:

3.1 Food Processing Industry

This chain is well-suited for food processing equipment, providing reliable performance and hygienic operation due to its stainless steel construction and corrosion-resistant properties.

3.2 Chemical Industry

With its resistance to chemicals and corrosive substances, this chain is ideal for use in chemical plants, ensuring safe and efficient operation in demanding environments.

3.3 Maritime Industry

The LH2444SS/BL1244SS Stainless Steel Leaf Chain is commonly used in marine applications, such as shipbuilding and offshore installations, where it withstands the corrosive effects of saltwater and harsh weather conditions.

4. How to Choose LH2444SS/BL1244SS Stainless Steel Leaf Chain?

When selecting the LH2444SS/BL1244SS Stainless Steel Leaf Chain for your specific application, consider the following factors:

4.1 Load Capacity

Determine the maximum load the chain needs to bear to ensure it meets the requirements of your application.

4.2 Environment

Consider the operating environment, including temperature, moisture, chemicals, or other corrosive elements, to ensure the chain's corrosion resistance matches the conditions it will be exposed to.

4.3 Length and Pitch

Choose the appropriate chain length and pitch to ensure proper fit and compatibility with your machinery and equipment.

5. Maintenance Tips for LH2444SS/BL1244SS Stainless Steel Leaf Chain

Proper maintenance is essential to maximize the lifespan and performance of the LH2444SS/BL1244SS Stainless Steel Leaf Chain. Follow these tips:

5.1 Regular Cleaning

Remove any dirt, debris, or contaminants from the chain's surface using a suitable cleaning agent and a soft brush or cloth.

5.2 Lubrication

Apply a recommended lubricant to the chain regularly to reduce friction and ensure smooth operation.

5.3 Inspection

Periodically inspect the chain for any signs of wear, damage, or elongation. Replace any worn-out or damaged components promptly to prevent further issues.

5.4 Storage

When not in use, store the chain in a dry and clean environment to prevent corrosion and maintain its performance.

Remember, proper maintenance and care will greatly extend the service life of your LH2444SS/BL1244SS Stainless Steel Leaf Chain.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales representative of Ever-power Group in the Netherlands. Our LH2444SS/BL1244SS Stainless Steel Leaf Chain is a prime example of our unique selling points, highlighting our superior product quality and exceptional service.

Our stainless steel roller chains are produced using high-quality materials and are manufactured to withstand harsh and demanding environments. In addition to our LH2444SS/BL1244SS chain, we offer a wide range of other stainless steel roller chains that are suitable for various applications.

At RP Techniek BV, we strive to provide our customers with the best possible service. We understand the importance of meeting customer needs and are committed to ensuring that all of our products are delivered on time and at a competitive price. Our production capabilities enable us to provide customized solutions to meet specific requirements and standards.

We are proud to offer a diverse selection of stainless steel roller chains that are suitable for use in a range of industries, including food processing, packaging, and manufacturing. Our products are made to withstand the toughest environments and deliver reliable performance.

Please see the attached image below for a visual representation of our high-quality stainless steel roller chains.

Sprockets for Sale

When it comes to pairing with the LH2444SS/BL1244SS Stainless Steel Leaf Chain, there are several suitable sprockets available. Our company provides a wide range of sprockets for sale, including different sizes, tooth counts, materials, and finishes to meet diverse industrial needs.

For the LH2444SS/BL1244SS Stainless Steel Leaf Chain, we recommend using a compatible sprocket with a minimum pitch diameter of 3.35 inches and a 13-tooth count. Our available sprockets are precision machined from high-quality materials, including stainless steel, carbon steel, and cast iron, and feature a variety of surface coatings, such as black oxide, zinc plating, and nickel plating.

Our sprockets are designed for efficient power transmission, reducing wear and tear on both the chain and sprocket, resulting in prolonged equipment life. We also offer custom-made sprockets to meet your specific requirements.

Check out our website or contact us for more information on our sprockets and other power transmission components.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...