In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

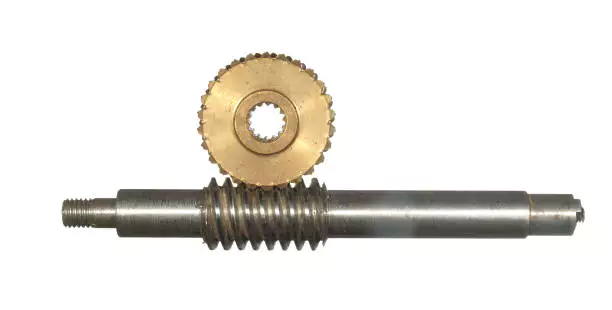

Hydraulic Worm Gear

The Hydraulic Worm Gear is a precision-engineered component designed for effective torque transmission and motion control. Made from high-strength steel and corrosion-resistant materials, the Hydraulic Worm Gear ensures durability and reliability in various applications. Its primary function is to provide smooth and efficient gear reduction, making it ideal for hydraulic systems.

Details of Hydraulic Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 10:1 |

| Input Torque | 50 Nm |

| Output Torque | 500 Nm |

| Efficiency | 85% |

| Max Input Speed | 1500 RPM |

| Material | Aluminum Alloy |

| Weight | 2.5 kg |

Features of Hydraulic Worm Gear

- High Load Capacity: Hydraulic Worm Gear is designed to handle substantial loads efficiently, making it suitable for various industrial applications.

- Compact Design: Its compact structure allows for installation in tight spaces, maximizing the use of available area.

- Enhanced Durability: Made from robust materials, Hydraulic Worm Gear offers long-lasting performance and resistance to wear and tear.

- Smooth Operation: The gear design ensures smooth and quiet operation, reducing noise levels during use.

Applications of Hydraulic Worm Gear in Industrial Machinery

The Hydraulic Worm Gear is an essential component in various industrial machinery applications. Known for its ability to provide high torque and efficient power transmission, the Hydraulic Worm Gear is widely utilized in conveyors, lifts, and other heavy-duty equipment. Its design allows for smooth operation and reliable performance under extreme conditions, making it ideal for industries such as manufacturing, construction, and automotive. By incorporating the Hydraulic Worm Gear into their systems, businesses can enhance productivity and ensure long-lasting durability in their machinery.

Manufacturing Process of Hydraulic Worm Gear

The manufacturing process of Hydraulic Worm Gear involves several key steps to ensure precision and performance. Here are the detailed stages:

- Material Selection: The first step in the production of Hydraulic Worm Gear is selecting the appropriate materials. High-quality metals such as alloyed steel are often chosen for their strength and durability. The selection process involves evaluating factors like tensile strength, corrosion resistance, and machinability to ensure the final product can withstand the demands of hydraulic applications.

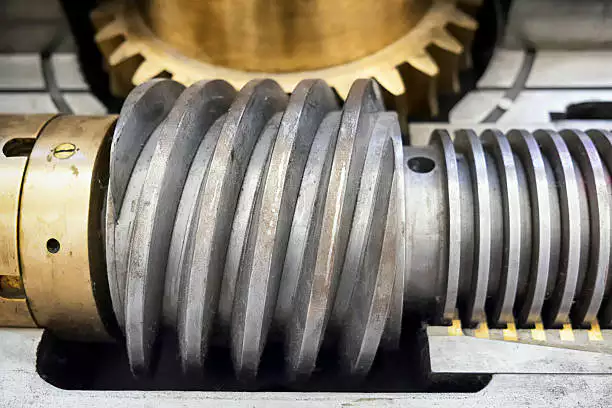

- Machining Components: Once materials are selected, the components of the Hydraulic Worm Gear are machined using advanced CNC (Computer Numerical Control) machines. This process allows for precise shaping of the worm and gear teeth, which are critical for the smooth operation. The accuracy achieved in this step impacts the efficiency and longevity of the gear system.

- Heat Treatment: After machining, the parts undergo heat treatment to enhance their mechanical properties. This process involves heating the components to specific temperatures followed by controlled cooling. Heat treatment improves the hardness and wear resistance of the Hydraulic Worm Gear, making it suitable for high-stress environments often found in hydraulic systems.

- Assembly: The assembly of the Hydraulic Worm Gear is a meticulous process that requires careful alignment of the worm and gear components. Proper assembly ensures that there is minimal backlash and maximum torque transmission. Skilled technicians perform this task to guarantee that the gear operates efficiently under various loads and conditions.

- Quality Control: Finally, rigorous quality control measures are implemented to test the performance of the Hydraulic Worm Gear. This includes inspection for dimensional accuracy, noise levels, and operational testing under load conditions. Quality assurance is crucial to ensure that the Hydraulic Worm Gear meets industry standards and customer expectations.

Worm Gear Supplier in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group, and we are proud to be one of the top ten worm gear suppliers in the Netherlands.

Our company specializes in Hydraulic Worm Gear products, which are known for their superior quality and performance. Here are some key points about our offerings:

- Exceptional Quality: Our hydraulic worm gears are manufactured to the highest standards, ensuring durability and reliability in various applications.

- Outstanding Performance: Designed for efficiency, our products provide smooth operation and excellent torque transmission.

- Strong Competence: With years of experience in the industry, we have built a strong reputation for innovation and expertise in worm gear technology.

- Comprehensive Service: We pride ourselves on our customer service, providing full support from selection to after-sales, ensuring a seamless experience for our clients.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...