Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Hydraulic Direction Cylinder Technical Parameters

| Technical Parameter | Value/Description |

|---|---|

| Rated Torque | 2800 N.m |

| Rated Pressure | 21 MPa |

| Rotation Angle | 180° |

| Displacement | 688 cc |

| Starting Pressure | Max 3.1 MPa |

| Maximum Bending Torque (Cross-Over Installation) | 16900 N.m |

| Maximum Bending Torque (Cantilever Installation) | 7100 N.m |

| Load in Diameter Direction | 2300 kg |

| Load in Length Direction | 1800 kg |

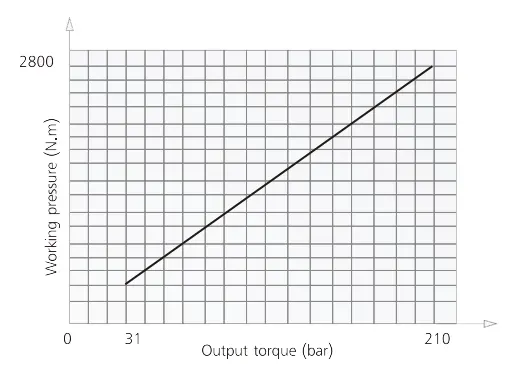

Diagram of the Relationship Between Working Pressure and Output Torque

The Hydraulic Direction Cylinder is a robust and reliable component designed for efficient motion control in various industrial applications. Engineered to deliver precise directional movement, this hydraulic cylinder ensures optimal performance under high-pressure conditions. With a rated torque of 2800 N.m and a rated pressure of 21 MPa, it is built to withstand demanding environments while providing smooth and consistent operation.

Key Features and Technical Specifications of Hydraulic Direction Cylinders

Superior Torque and Pressure Handling

Designed to operate under high stress, the Hydraulic Direction Cylinder offers a maximum rated torque of 2800 N.m, ensuring reliable performance in heavy-duty applications. Its 21 MPa rated pressure enables effective force transmission for various hydraulic systems.

Extended Rotation Angle for Versatile Applications

With a 180° rotation angle, this hydraulic cylinder allows for extensive directional control, making it suitable for precision-based industrial and mechanical applications. The 688 cc displacement ensures stable and efficient fluid movement within the system.

Low Starting Pressure for Efficient Activation

The Hydraulic Direction Cylinder operates with a maximum starting pressure of 3.1 MPa, allowing for quick and efficient actuation. This feature enhances energy efficiency and reduces the load on hydraulic power systems.

Exceptional Load-Bearing Capacity

Built for durability, this hydraulic cylinder can withstand high external forces. It supports a diameter direction load of 2300 kg and a length direction load of 1800 kg, making it ideal for demanding industrial tasks.

High Bending Torque for Structural Stability

- Cross-over installation: Maximum bending torque of 16900 N.m, ensuring structural integrity under dynamic loads.

- Cantilever installation: Maximum bending torque of 7100 N.m, providing stability in applications requiring extended reach and support.

Applications of Hydraulic Direction Cylinder

The Hydraulic Direction Cylinder is widely used in industrial machinery, construction equipment, and automated systems where precise directional movement is required. Its robust design and high load capacity make it an essential component in:

- Heavy-duty hydraulic systems

- Automated industrial processes

- Construction and lifting equipment

- Marine and offshore applications

Why Choose Techniek BV Hydraulic Direction Cylinder?

Our Hydraulic Direction Cylinder is engineered for durability, precision, and efficiency. It delivers optimal performance in demanding conditions, ensuring long service life and minimal maintenance. Whether for industrial automation or heavy machinery, this hydraulic cylinder guarantees superior directional control and enhanced operational efficiency.

Get in Touch

Looking for a Hydraulic Direction Cylinder tailored to your needs? Contact us today to discuss your requirements and explore our range of high-quality hydraulic solutions.

Additional information

| Edited by | Sylvia |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...