In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications of H79 Mill Chain

The H79 Mill Chain has the following parameters:

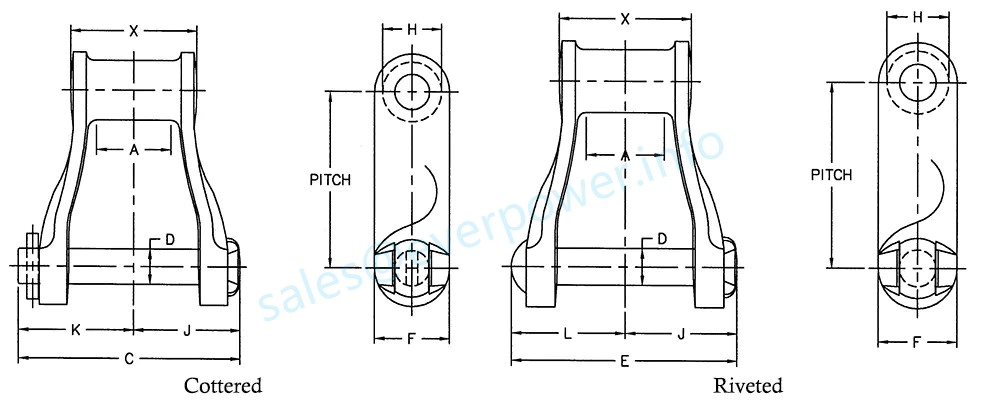

| CHAIN NO. | LINKS | PINS | PITCH IN INCHES | LINKS PER 10 FEET | WEIGHT PER FOOT LBS. | AVERAGE ULTIMATE STRENGTH LBS. | RECOMMENDED MAXIMUM WORKING LOAD LBS. | CHAIN CONSTRUCTION | AVAILABLE ATTACHMENTS | MAXIMUM ALLOWABLE SPROCKET FACE A | OVERALL WIDTH¡ª COTTERED C | DIAMETER OF PIN D | OVERALL WIDTH¡ª RIVETED E | HEIGHT OF SIDEBARS F | DIAMETER OF BARREL H | HEAD OF PIN TO CENTER LINE J | END OF PIN TO CENTER LINE¡ª COTTERED K | END OF PIN TO CENTER LINE¡ª RIVETED L | BEARING LENGTH X |

| H 60 | ALL NUMBERS A-L Primal |

ALL NUMBERS Carbon Steel, Heat-Treated | 2.308 | 52 | 2.1 | 9450 | 1560 | Riveted or Cottered | H2, K1 | 0.75 | 2.62 | 0.312 | 2.62 | 0.75 | 0.75 | 1.25 | 1.38 | 1.38 | 1.50 |

| H 74 | 2.609 | 46 | 3.0 | 13500 | 1850 | Riveted or Cottered | F4 | 1.00 | 3.12 | 0.375 | 2.88 | 1.00 | 0.88 | 1.50 | 1.62 | 1.62 | 1.66 | ||

| H 78 | 2.609 | 46 | 4.2 | 22200 | 2810 | Riveted or Cottered | A1, F4, F8, G19, H1, H2, K1, K2 | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 79 | 2.609 | 46 | 4.8 | 24300 | 2810 | Riveted or Cottered | None | 1.12 | 3.31 | 0.500 | 3.19 | 1.12 | 0.88 | 1.56 | 1.62 | 1.62 | 1.88 | ||

| H 82 | 3.075 | 39 | 5.5 | 27000 | 3580 | Riveted or Cottered | K2 | 1.25 | 3.88 | 0.562 | 3.88 | 1.25 | 1.22 | 1.88 | 2.00 | 2.00 | 2.12 | ||

| H 87 | 4.000 | 30 | 6.5 | 33750 | 4450 | Riveted or Cottered | None | 1.50 | 4.38 | 0.625 | 4.19 | 1.38 | 1.38 | 2.06 | 2.12 | 2.12 | 2.38 | ||

| H 124 | 4.000 | 30 | 8.8 | 40500 | 6180 | Riveted or Cottered | K2 | 1.62 | 4.88 | 0.750 | 4.75 | 1.56 | 1.44 | 2.25 | 2.50 | 2.50 | 2.75 |

Introduction

The H79 Mill Chain is a high-quality, durable chain designed specifically for use in mill applications. With its advanced design and exceptional strength, this chain offers superior performance and reliability in demanding industrial environments.

Key Features

1. High Strength: The H79 Mill Chain is constructed using premium-grade materials, ensuring maximum strength and load-bearing capacity.

2. Enhanced Durability: The chain is engineered to withstand heavy-duty applications, providing long-lasting performance even in harsh operating conditions.

3. Precision Engineering: Each component of the chain is meticulously manufactured to precise specifications, ensuring optimal fit and smooth operation.

Applications

The H79 Mill Chain is ideally suited for a wide range of mill applications, including:

- Steel Mills

- Paper Mills

- Lumber Mills

- Textile Mills

Technical Specifications

1. Chain Pitch: 79mm

2. Breaking Load: 100 kN

3. Weight: 2.5 kg/m

Benefits

1. Increased Productivity: The H79 Mill Chain's exceptional strength and durability minimize downtime, resulting in improved productivity and reduced maintenance costs.

2. Enhanced Safety: The chain's reliable performance ensures a safe working environment for operators, reducing the risk of accidents and injuries.

3. Cost-Effective Solution: With its long lifespan and minimal maintenance requirements, the H79 Mill Chain offers a cost-effective solution for mill operators.

Conclusion

When it comes to mill applications, the H79 Mill Chain is the ideal choice for superior performance, durability, and reliability. Its advanced design and precision engineering make it the go-to chain for a wide range of industrial environments. Invest in the H79 Mill Chain today and experience the difference it can make in your mill operations.

Choose Our Malleable Casting Chains

RP Techniek BV proudly represents Ever-power Group as their sales agent in the Netherlands. Our malleable casting chains are a unique selling point, especially the H79 Mill Chain. We take pride in our exceptional product quality, excellent customer service, and unmatched manufacturing capabilities.

Our malleable cast iron chains are designed to withstand the most rigorous applications, making them ideal for heavy-duty industrial machinery. What sets our chains apart is their ability to provide exceptional performance even under extreme conditions. We utilize state-of-the-art technology in our manufacturing facilities, ensuring the highest level of quality in every chain we produce.

At RP Techniek BV, we offer a wide variety of casting chains for sale, including but not limited to our malleable cast iron chains. Our extensive product line is designed to meet the requirements of various industries and applications.

We believe in providing our customers with the best quality products and services to meet their needs. Our team of experts is always ready to assist with any inquiries or concerns you may have.

Please check out the image below to get a glimpse of our manufacturing facility:

Sprockets for Sale

When it comes to pairing chains with sprockets, the H79 Mill Chain is an ideal choice. Our company provides a wide variety of sprockets for sale, including those specifically designed for the H79 Mill Chain. These sprockets are made with high-quality materials and precise manufacturing techniques to ensure maximum durability and performance.

In addition to our H79 Mill Chain sprockets, we offer sprockets for other chain types as well, including ANSI standard chains, British standard chains, and specialty chains. Our sprockets are available in a range of sizes and tooth configurations to suit a variety of applications.

We pride ourselves on providing our customers with the highest quality sprockets at competitive prices. Whether you need a single replacement sprocket or a large quantity for a production run, we have the inventory and expertise to meet your needs.

Please see the image below for an example of our sprocket offerings.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...