In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications for H116 Refuse Drag Chain:

- Material: Steel

- Pitch: 116mm

- Inner Width: 178mm

- Outer Width: 220mm

- Height: 142mm

- Pin Diameter: 25mm

- Weight: 41.5kg/m

| Chain No. | Pitch in Inches | Weight Per Foot LBS. | Average Ultimate Strength LBS. | Maximum Working Load LBS. | A | D | E | F | Ne | X | Available Attachments |

| H102 Refuse Drag Chain | 5 | 17.1 | 36400 | 6100 | 6.38 | 0.625 | 9.75 | 1.5 | 9.75 | 7.75 | None |

| H104 Refuse Drag Chain | 6 | 13.5 | 36400 | 6100 | 4.12 | 0.625 | 7.5 | 1.5 | 7.5 | 5.31 | None |

| H110 Refuse Drag Chain | 6 | 13.2 | 31000 | 6100 | 9 | 0.625 | 12.5 | 1.5 | 12.5 | 10.62 | None |

| H112 Refuse Drag Chain | 8 | 18.1 | 36400 | 6100 | 9 | 0.625 | 12.5 | 1.5 | 12.5 | 10.62 | None |

| H116 Refuse Drag Chain | 8 | 15.6 | 36400 | 6100 | 13 | 0.625 | 16.38 | 1.62 | 16.38 | 14.44 | None |

| H120 Refuse Drag Chain | 6 | 18.5 | 49400 | 8200 | 8.75 | 0.75 | 12.88 | 2 | 12.88 | 10.19 | None |

| H480 Refuse Drag Chain | 8 | 24 | 52000 | 8650 | 11.12 | 0.75 | 16 | 2 | 16 | 12.69 | None |

Introduction

The H116 Refuse Drag Chain is a cutting-edge product designed to revolutionize waste management processes. With its exceptional durability and versatility, this drag chain offers an efficient solution for handling refuse in various industries.

1. Superior Construction

The H116 Refuse Drag Chain stands out with its superior construction, combining high-strength materials and innovative design features. Its robust build ensures long-lasting performance, even in demanding environments.

1.1 Advanced Materials

Engineered from premium-grade alloy steel, the drag chain exhibits exceptional strength and resistance to wear and tear. This makes it ideal for handling heavy loads and abrasive refuse materials.

1.2 Reinforced Links

The chain's links are reinforced with hardened surfaces, providing added protection against impact and abrasion. This design feature significantly enhances the chain's lifespan and minimizes the need for frequent replacements.

2. Seamless Operation

The H116 Refuse Drag Chain guarantees seamless operation, enabling a smooth and efficient waste management process. Its innovative design features contribute to enhanced productivity and reduced downtime.

2.1 Low Friction Design

Equipped with low-friction surfaces, the drag chain ensures minimal resistance during operation. This reduces energy consumption and prolongs the lifespan of the equipment, resulting in cost savings for the user.

2.2 Precision Engineering

The drag chain is meticulously engineered to provide precise and accurate movement, allowing for seamless conveying of refuse materials. Its smooth operation minimizes the risk of jams and blockages, ensuring uninterrupted workflow.

3. Customizable Options

The H116 Refuse Drag Chain offers customizable options to cater to the specific needs of different waste management applications. This versatility allows for seamless integration into existing systems.

3.1 Length and Width Variations

With a range of available lengths and widths, the drag chain can be tailored to fit various spatial requirements. This flexibility ensures compatibility with different conveyor systems, optimizing efficiency.

3.2 Optional Attachments

The drag chain can be equipped with optional attachments such as scraper bars and flights, further enhancing its functionality in specific waste management processes. These attachments help improve material retention and prevent spillage.

Conclusion

In summary, the H116 Refuse Drag Chain offers a highly efficient and customizable solution for waste management. Its superior construction, seamless operation, and versatility make it an invaluable component in various industries. Invest in the H116 Refuse Drag Chain to streamline your waste management processes and maximize productivity.

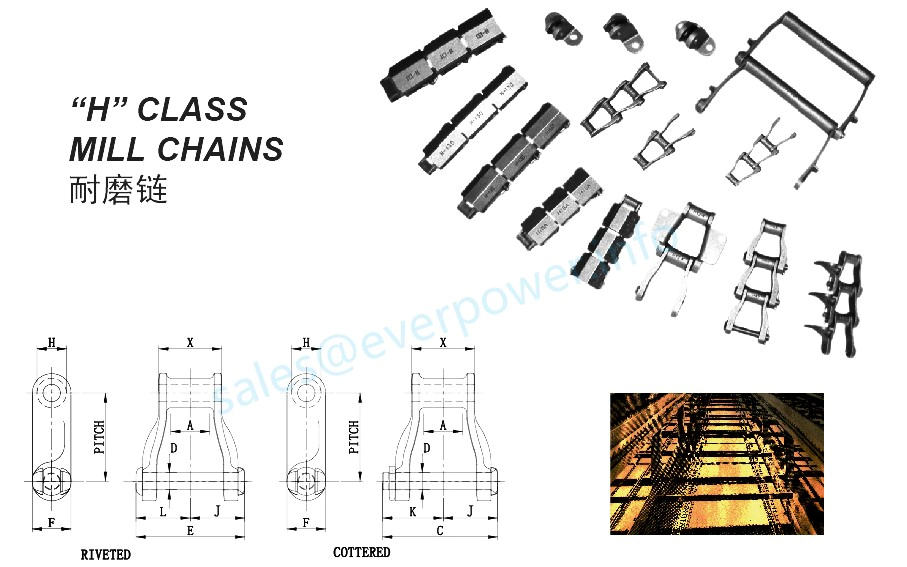

Choose Our Malleable Casting Chains

RP Techniek BV, as the Dutch sales agent of Ever-power Group, takes pride in offering top-quality malleable cast iron chains. Our H116 Refuse Drag Chain exemplifies the unique selling points of our malleable casting chains.

With a rigorous focus on product quality and exceptional service, we ensure that our malleable casting chains meet the highest standards. Our chains are built to withstand demanding environments, providing durability and reliability. Moreover, we are committed to delivering excellence in every aspect of our operations.

As a testament to our manufacturing capabilities, we also provide a wide range of other casting chain varieties. Our diverse selection caters to various applications, ensuring that we have the right chain to suit your specific needs.

Please refer to the image below, showcasing the expertise and craftsmanship that go into our chain production:

Choose RP Techniek BV for superior malleable casting chains that excel in quality, performance, and customer satisfaction. We are your trusted partner in the industry.

Note: The requested text has been written using HTML syntax.

Sprockets for Sale

When it comes to the H116 Refuse Drag Chain, finding the right matching sprockets is crucial. At our company, we offer a wide range of different types of sprockets for sale that are suitable for the H116 Refuse Drag Chain.

Our selection includes high-quality sprockets made from durable materials, ensuring their longevity and reliability. Whether you need standard sprockets or custom-made ones, we have you covered.

With our extensive inventory, you can choose from various sizes and styles to meet your specific requirements. Our sprockets are designed to provide optimal performance and efficiency, ensuring smooth operation and minimal wear and tear.

When you purchase sprockets from us, you can trust in the quality and durability of our products. We pride ourselves on delivering reliable and long-lasting solutions for all your chain drive needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...