In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

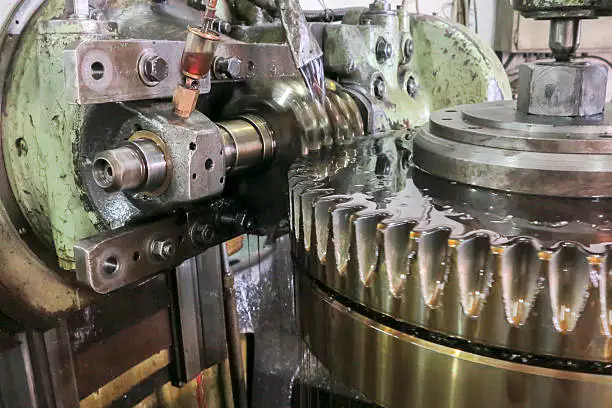

Globoid Worm Gear

The Globoid Worm Gear is a highly efficient mechanical component designed for power transmission. Made from durable materials such as high-strength steel or aluminum, the Globoid Worm Gear ensures long-lasting performance. Its primary function is to provide precise motion control and reduce speed in various machinery applications, making it essential in industries requiring reliable gearing solutions.

Details of Globoid Worm Gear

| Parameter | Value |

|---|---|

| Gear Ratio | 1:5 |

| Material | Aluminum Alloy |

| Efficiency | 90% |

| Output Torque | 50 Nm |

| Max Input Speed | 3000 RPM |

| Dimensions | 150 x 100 x 80 mm |

| Weight | 1.5 kg |

Key Features of Globoid Worm Gear

- High Efficiency: Globoid Worm Gears are designed to minimize friction and improve power transmission efficiency. This results in reduced energy consumption and prolonged equipment life.

- Compact Design: Their unique design allows for a compact layout, making them suitable for applications with limited space while still delivering high torque output.

- Versatile Applications: Globoid Worm Gears are versatile and can be used in various industries, including manufacturing, robotics, and automotive, enhancing the adaptability of machinery.

Applications of Globoid Worm Gear in Various Industries

The Globoid Worm Gear is an essential component widely used in various industrial applications due to its unique design and efficiency. This type of gear system is particularly effective in providing high torque and compactness, making it ideal for use in conveyors, robotics, and automotive systems. The Globoid Worm Gear facilitates smooth and precise motion control, which is crucial in high-performance machinery. Its capability to reduce speed while increasing torque makes it a preferred choice for engineers looking to optimize their designs across different sectors.

Manufacturing Process of Globoid Worm Gear

- Material Selection: The first step in the manufacturing process of the Globoid Worm Gear involves selecting high-quality materials that exhibit excellent wear resistance and mechanical properties. Common materials include alloy steel or bronze, which are chosen based on the gear's application requirements. The choice of material is critical as it directly impacts the durability and performance of the Globoid Worm Gear in various industrial settings.

- CNC Machining: Once the material is finalized, the next step is CNC (Computer Numerical Control) machining. This precise process shapes the material into the required dimensions and forms of the Globoid Worm Gear. CNC machines ensure that tolerances are maintained within specified limits, which is essential for achieving the desired meshing characteristics with worm shafts. This step guarantees that the Globoid Worm Gear will function effectively in its intended application.

- Heat Treatment: After machining, the Globoid Worm Gear undergoes heat treatment to enhance its hardness and wear resistance. This process typically involves quenching and tempering, which alters the microstructure of the material. Heat treatment is crucial for ensuring that the Globoid Worm Gear can withstand the operational stresses it will encounter during use, thus prolonging its service life and efficiency.

- Finishing Operations: The final stage of the manufacturing process includes finishing operations such as grinding and polishing. These steps refine the surface of the Globoid Worm Gear, reducing friction and improving its overall performance. A smooth surface finish is vital for ensuring efficient power transmission and minimizing wear over time. The finishing operations not only enhance the aesthetic appeal of the Globoid Worm Gear but also its functional reliability.

Worm Gear Supplier in Holland

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, and we are proud to be one of the top ten worm gear suppliers in the country.

Our product line includes:

- Globoid Worm Gears: Designed for high efficiency and reliability, these gears are suitable for various industrial applications.

- Superior Quality: Our products are manufactured using the highest quality materials, ensuring durability and performance.

- Expertise: With years of experience in the industry, we possess the technical knowledge to meet diverse customer needs.

- Exceptional Service: We pride ourselves on providing outstanding customer support, ensuring a seamless experience from consultation to delivery.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...