Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

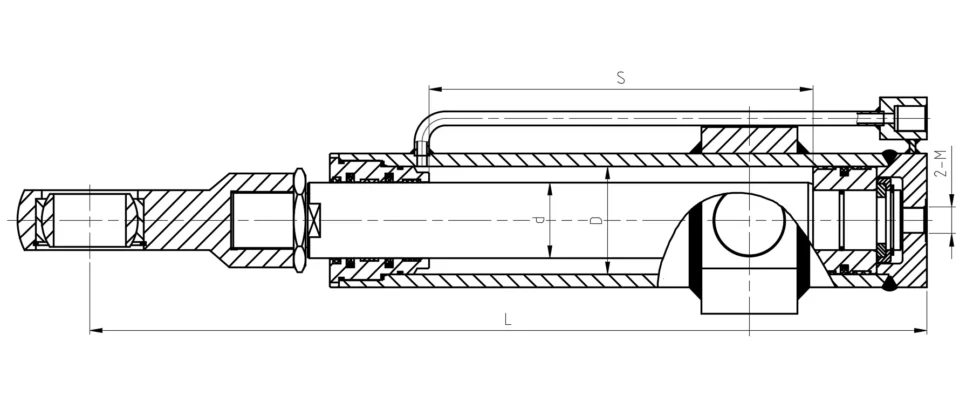

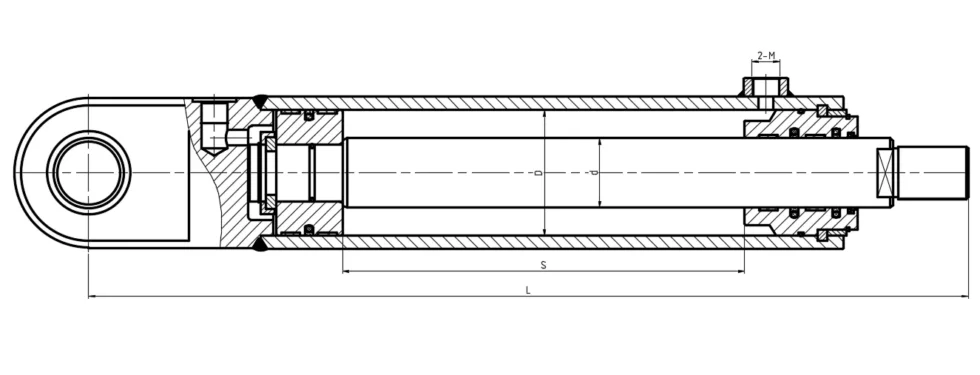

Specification of Forward Thrust Cylinder for Sanitation Machinery

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Forward thrust cylinder | LPE416B.4.4-2-00 | Φ90 | Φ63 | 320 | 878 | 16MPa | 2-M22*1.5 | 47kg |

|

|

| Cylinder Name | Drawing number | Bore diameter (D) | Rod diameter (d) | Stroke (S) | Installation distance (L) | Working pressure | Interface dimensions (M) | Weight |

| Forward thrust cylinder | LPG418.4.4-2-00 | Φ100 | Φ55 | 320 | 700 | 16MPa | 2-M22*1.5 | 41kg |

Introduction to Forward Thrust Cylinder in Sanitation Machinery

The forward thrust cylinder operates through the principle of pushing fluid into one end of the cylinder, which in turn pushes out from the other end, enabling linear motion. This mechanism provides an efficient means of converting hydraulic energy into mechanical movement. The design allows for smooth and powerful action, making it a vital component in various machinery, particularly in sanitation vehicles.

One of the key features of the forward thrust cylinder is its alignment with the direction of the force applied by the hydraulic system. This alignment not only enhances the transmission efficiency but also contributes to a more stable power output. As the fluid pressure builds within the cylinder, the resultant push aligns perfectly with the intended direction of movement, ensuring that operations are carried out seamlessly and with minimal energy loss.

The performance characteristics of the forward thrust cylinder include high thrust capabilities, excellent rigidity, and smooth motion. These attributes make it particularly effective in applications that require significant pushing, stretching, compacting, and lifting forces. Its robustness allows it to withstand the demanding conditions often encountered in heavy-duty operations, making it a reliable choice for various industrial applications.

In the context of sanitation vehicles, the forward thrust cylinder plays a crucial role in tasks that require stable and powerful pushing motions, such as garbage compression and loading operations. Its capability to exert substantial force ensures that waste is efficiently compacted and transported, enhancing the overall operational effectiveness of the vehicle.

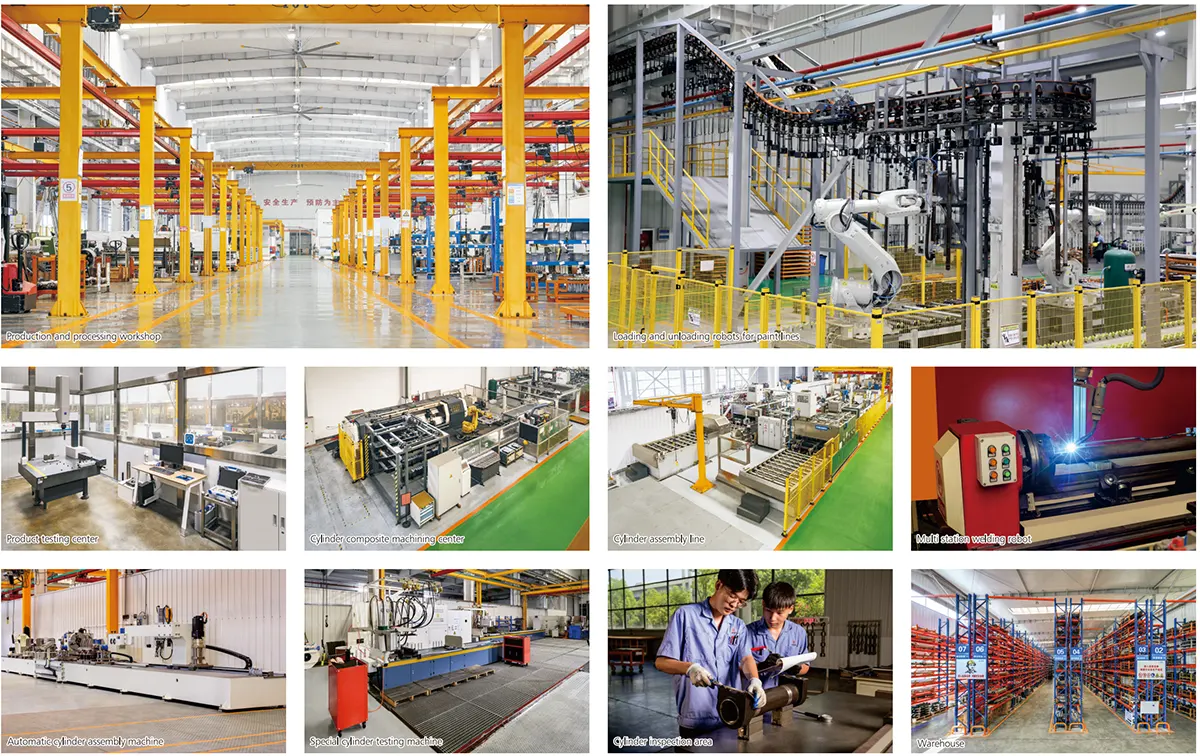

Hydraulic Cylinders for Sanitary Vehicles Manufacturer

Techniek BV is the Dutch sales agent for Ever-power Group, a leading manufacturer in the hydraulic cylinder industry. Our commitment to quality and innovation positions us as a reliable partner for businesses in the sanitation machinery sector. We specialize in producing high-performance hydraulic cylinders, such as the Forward Thrust Cylinder for Sanitation Machinery, designed to meet the rigorous demands of the industry. Our products are engineered to provide optimal efficiency and durability, ensuring seamless operation in various applications.

In addition to our standard hydraulic cylinders, we offer customized solutions tailored to meet specific client requirements. We can manufacture non-standard cylinders with a diameter of D360MM and a stroke length of L6000MM, accommodating unique specifications and designs. We invite customers to collaborate with us, providing drawings or samples for bespoke cylinder solutions that perfectly fit their operational needs.

Additional information

| Edited by | Sylvia |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...