Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

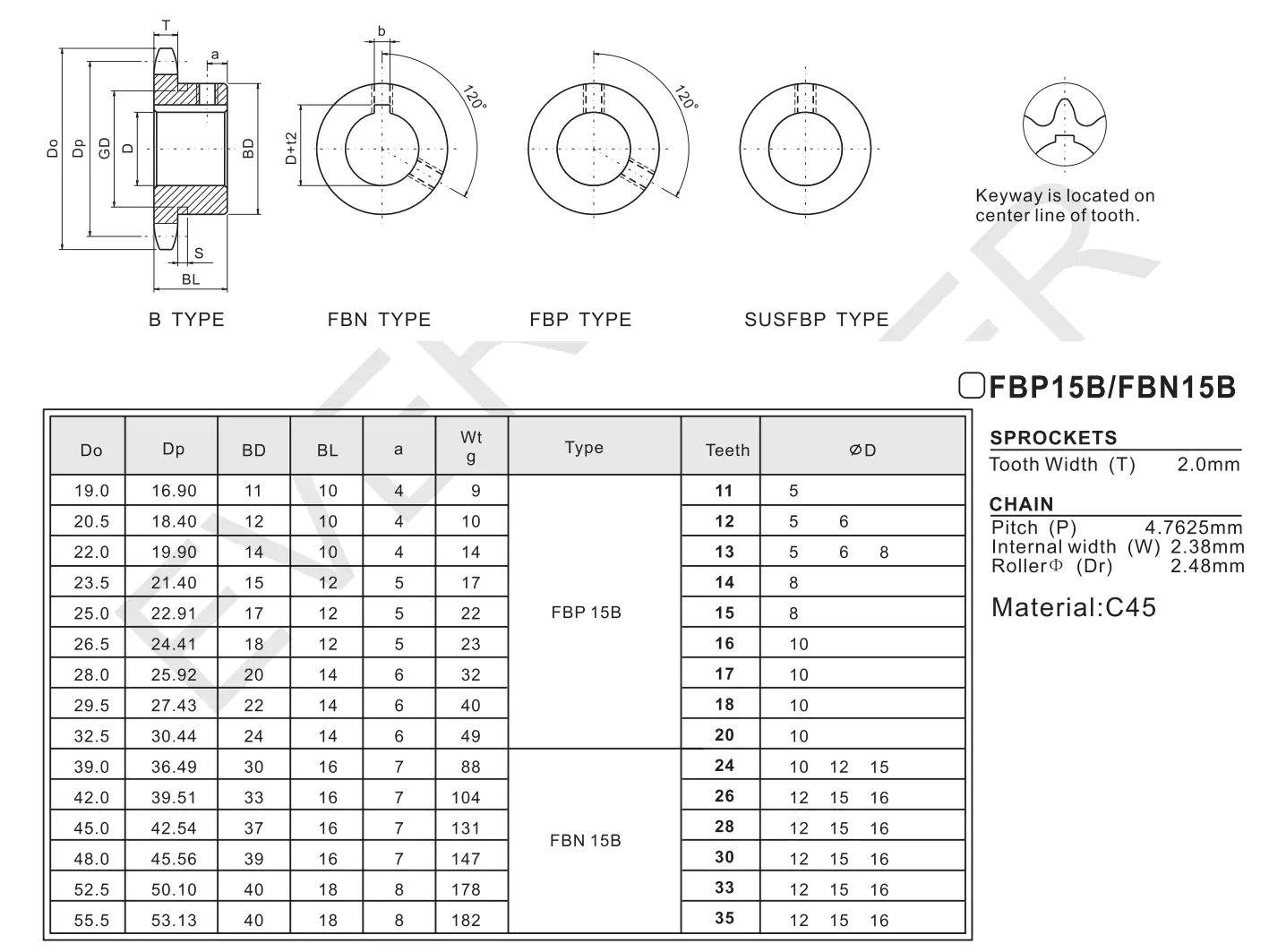

FBP15B FBN15B Finished Bore Sprocket

The FBP15B and FBN15B Finished Bore Sprockets are expertly designed for durability and precision. These high-quality sprockets ensure seamless power transmission in various applications. Crafted from premium materials, they provide reliable performance and longevity, making them an ideal choice for industrial machinery and equipment. Enhance your operations with our trusted sprockets.

Specifications of FBP15B FBN15B Finished Bore Sprocket

A finished bore sprocket is a specialized type of chain sprocket that features a pre-bored hole, allowing it to seamlessly fit onto a specific shaft diameter. This design significantly simplifies installation, as the sprocket is already machined with the necessary hole. RP Techniek BV provides the FBP15B and FBN15B finished bore sprockets, which are engineered for compatibility with a diverse range of applications.

Materials and Manufacturing Process

Our finished bore sprockets are crafted from materials such as high carbon steel, alloy steel, or stainless steel, tailored to meet specific application demands. The manufacturing process encompasses several stages, including meticulous material selection, precise cutting, punching, forging, machining, heat treatment, surface hardening, surface treatment, and rigorous quality inspection.

- Material Selection: We meticulously choose suitable materials based on application requirements, encompassing factors like load capacity, corrosion resistance, and temperature tolerance.

- Cutting: Advanced cutting machines are employed to transform raw materials into the required sizes and shapes with precision.

- Punching and Forging: High-precision punching and forging machines are utilized to mold raw materials into the desired sprocket shape.

- Machining: Various machining techniques, including turning, milling, drilling, and boring, are applied to achieve precise dimensions and tolerances.

- Heat Treatment: Heat treatment processes, such as quenching and tempering, are implemented to attain the desired hardness, strength, and toughness of the sprocket.

- Surface Hardening: Surface hardening techniques, including carburizing and nitriding, are used to enhance wear resistance and extend the sprocket's service life.

- Surface Treatment: We employ different surface treatment techniques, such as plating, painting, and oiling, to improve corrosion resistance and enhance appearance.

- Quality Inspection: Strict quality inspections, including dimensional measurement, surface inspection, and performance testing, ensure that our sprockets meet all specified requirements.

Applications of Finished Bore Sprocket

Finished bore sprockets find extensive application across various industries, including heavy machinery, food processing and packaging, chemical and pharmaceutical sectors, assembly lines, as well as logistics and warehousing. These sprockets are integral components that facilitate the transmission of power and motion between rotating shafts and chains, playing a crucial role in numerous mechanical systems.

Maintenance and Troubleshooting

To maximize performance and longevity of the finished bore sprocket, regular maintenance and troubleshooting are essential. Here are some recommended practices:

- Daily Inspection: Regularly examine the sprocket for signs of wear, damage, or misalignment. Ensure that all bolts and nuts are securely tightened.

- Cleaning: Clean the sprocket on a regular basis to eliminate dirt, debris, and rust. Utilize a brush, cloth, or compressed air to efficiently clean the teeth and bore.

- Lubrication: Apply an appropriate lubricant to the sprocket teeth and bore to minimize friction and wear. Select a high-quality lubricant that is suitable for the working conditions.

- Adjustment and Calibration: Regularly check the tension and alignment of the chain. Use a tension gauge and alignment tool for precise adjustments and calibrations of both the sprocket and chain.

- Common Problems and Solutions: Below are common issues associated with finished bore sprockets, along with their solutions:

- Skipping Teeth: This issue may arise from a loose chain, worn teeth, or misalignment. Tighten the chain, replace the sprocket, or make necessary alignment adjustments.

- Broken Teeth: Often caused by overloading, fatigue, or impact. Replace the sprocket, reduce the load, or prevent impacts to avoid this problem.

- Wear: Abrasion, corrosion, or fatigue can lead to wear over time. Replace the sprocket, apply suitable surface treatments, or enhance lubrication practices.

- Noise: Vibration, misalignment, or insufficient lubrication can produce unwanted noise. Adjust alignment, enhance lubrication, or consider installing a vibration damper.

- Chain Slip: Similar to skipping teeth, this may stem from a loose chain, worn teeth, or misalignment. Tighten the chain, replace the sprocket, or correct alignment as needed.

Other Types of Sprockets and Chains

Alongside the finished bore sprocket, RP Techniek BV also provides an array of other sprocket types, including taper lock sprockets, QD sprockets, and idler sprockets. Our selection extends to a variety of chains, including roller chains, conveyor chains, and agricultural chains. Regardless of your specific needs and requirements, we are dedicated to delivering high-quality products and exceptional service.

Sprockets Supplier in the Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, offering high-quality sprockets and related products to our clientele. Our featured products include the FBP15B and FBN15B Finished Bore Sprockets, renowned for their robust construction and precise engineering. These sprockets are designed to fulfill diverse industrial requirements, ensuring optimal performance across various machinery and equipment.

In addition to our standard offerings, we also specialize in custom solutions based on specific customer specifications. We welcome clients to present their designs and samples for tailored solutions that meet their unique needs.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...