Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

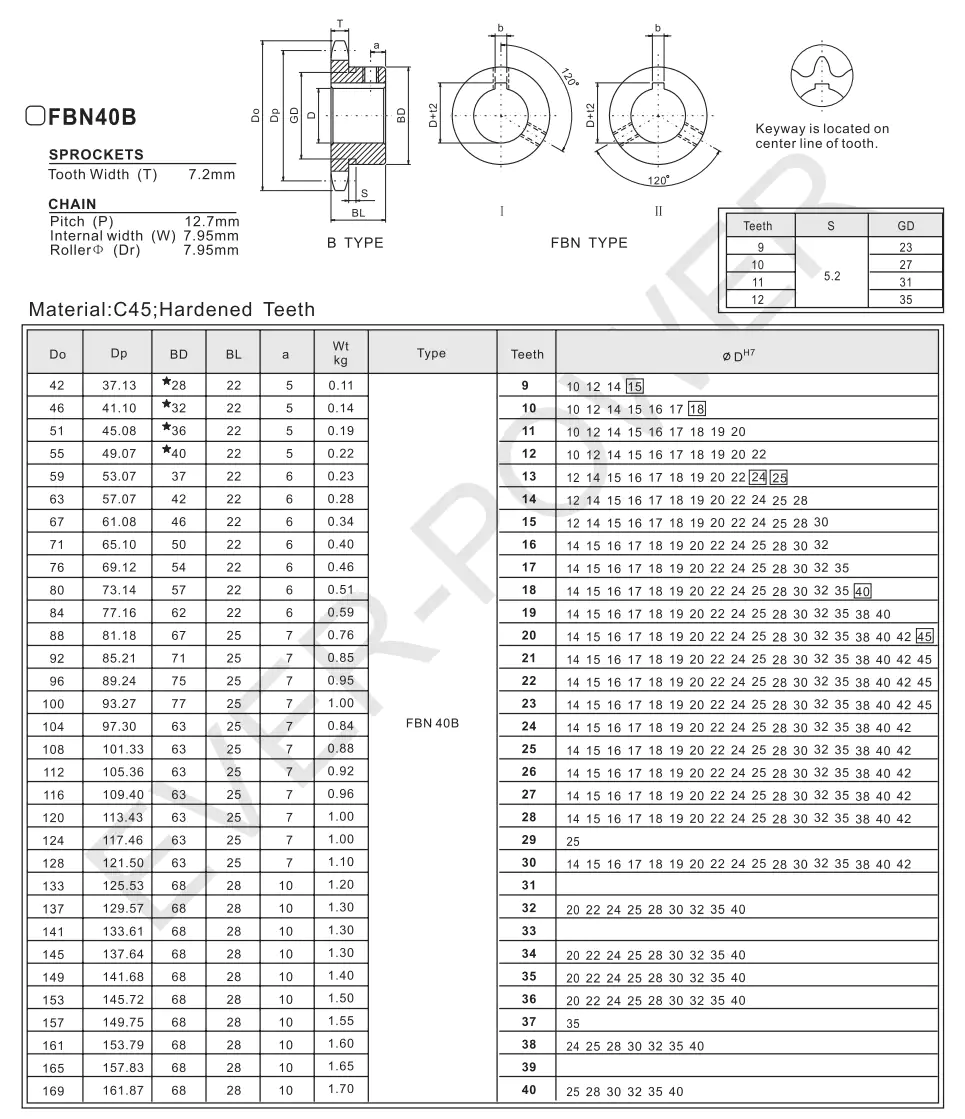

FBN40B Finished Bore Sprocket

The FBN40B Finished Bore Sprocket is designed for optimal performance in various applications. Crafted from high-quality materials, it ensures durability and reliability. With precise engineering, this sprocket facilitates smooth power transmission and is compatible with a range of chains. Ideal for industrial machinery and automotive use, it delivers consistent performance.

Specifications of FBN40B Finished Bore Sprocket

The FBN40B finished bore sprocket features a meticulously designed pre-bored hole, which significantly simplifies the installation process onto a shaft without the need for further machining. This sprocket is an exceptional choice for a wide range of applications, attributing its reputation to its robustness and adaptability. Below are additional details regarding this product:

Materials and Manufacturing Process

- Materials: High carbon steel, alloy steel, or stainless steel

- Manufacturing process: Material selection, cutting, stamping, forging, machining, quenching and tempering, surface hardening, rust prevention, quality inspection

The use of high-quality materials and meticulous manufacturing processes ensures that the FBN40B sprocket is not only robust but also durable, making it capable of enduring heavy loads and considerable wear over time.

Applications

The FBN40B finished bore sprocket finds its applications across various industries, including:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceuticals

- Assembly lines

- Logistics and warehousing

These sectors require reliable and durable sprockets to facilitate seamless operations, and the FBN40B sprocket is designed to meet those demanding standards effortlessly.

Maintenance and Troubleshooting

To ensure the longevity and efficient performance of the FBN40B finished bore sprocket, proper maintenance is essential. Here are some valuable maintenance tips:

- Conduct daily inspections and cleaning routines

- Ensure proper lubrication is applied as needed

- Regularly adjust and calibrate the sprocket

Despite regular upkeep, certain issues may arise, such as jumping teeth, breakage, wear, excessive noise, or chain slippage. Below are some common problems along with their solutions:

- Jumping teeth: Adjust the chain tension or replace the sprocket if you notice signs of wear

- Breakage: Replace either the sprocket or the chain if any component is worn or damaged

- Wear: If either the sprocket or chain is beyond repair, a replacement is necessary

- Excessive noise: Investigate potential misalignment or tension issues, and lubricate the chain

- Chain slippage: Adjust the tension or consider replacing the chain if it appears worn

Other Products

In addition to the FBN40B finished bore sprocket, we offer a variety of sprocket types including taper lock sprockets, QD sprockets, idler sprockets, and various models of chains. Below is an image of one of our transmission sprockets:

Our extensive selection of products ensures that we can provide our customers with optimal solutions tailored to their specific requirements.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, specializing in delivering high-quality sprocket solutions suited for various industrial applications. One of our highlighted products is the FBN40B Finished Bore Sprocket, which exemplifies our unwavering commitment to quality and reliability. This sprocket is engineered to adhere to rigorous industry standards, guaranteeing optimal performance within your machinery and systems.

Beyond our standard offerings, we take pride in our capability to deliver customized solutions tailored to the unique needs of our clients. Customers are encouraged to share drawings or samples for any non-standard customization, enabling us to create sprockets precisely designed for their distinct applications.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...