In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications for D88C Stainless Steel Pintle Chain

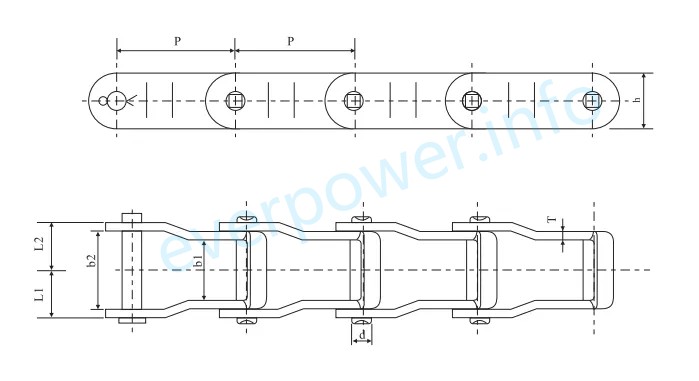

This section outlines the detailed specifications of stainless steel pintle chains.

Introduction of D88C Stainless Steel Pintle Chain

This article presents an in-depth overview of the D88C Stainless Steel Pintle Chain, detailing its construction, material composition (stainless steel), and operational benefits. Designed for durability, this chain is ideal for an array of industrial uses. The image below depicts the stainless steel pintle chain.

Advantages of D88C Stainless Steel Pintle Chain

The D88C Stainless Steel Pintle Chain offers numerous benefits compared to other chain types. Firstly, it is constructed from premium stainless steel, making it highly resistant to rust and corrosion, even in challenging conditions. This feature ensures a longer lifespan and less maintenance compared to chains made from inferior materials.

Furthermore, the D88C Pintle Chain is designed for easy assembly and disassembly, making it an excellent option for applications that require regular adjustments or maintenance.

Another significant benefit of the D88C Stainless Steel Pintle Chain is its robustness and longevity. It can withstand heavy loads and high speeds without degrading, making it perfect for demanding applications.

In summary, the D88C Stainless Steel Pintle Chain is a dependable and adaptable choice for various industrial tasks. Its corrosion resistance, low maintenance needs, and exceptional durability provide excellent value for companies seeking a reliable chain solution.

Applications of D88C Stainless Steel Pintle Chain

The D88C Stainless Steel Pintle Chain is a versatile and dependable option that is utilized across multiple applications. Below are specific areas where this chain is employed:

- Food Processing Industry: The D88C Stainless Steel Pintle Chain is particularly well-suited for the food processing sector due to its corrosion-resistant properties and ability to withstand high temperatures. It is commonly used in conveyors, washers, and dryers.

- Bottling Plants: This chain is essential in bottling facilities for transporting bottles between different stages. Its resistance to corrosion makes it ideal for environments exposed to moisture and chemicals.

- Chemical Industry: In the chemical sector, the D88C Stainless Steel Pintle Chain is utilized for transporting chemicals and hazardous materials. Its resistance to high temperatures and corrosion makes it a reliable choice in demanding conditions.

- Packaging Industry: The chain is frequently employed in packaging machinery for the movement and packing of various products. Its strength and durability render it perfect for high-speed packaging equipment.

Maintenance of D88C Stainless Steel Pintle Chain

Effective maintenance of the D88C stainless steel pintle chain is vital for maximizing its performance and longevity. Below are some maintenance recommendations:

- Regularly clean the chain: Use a high-pressure water hose or a soft brush to eliminate dirt, debris, and other contaminants. Avoid wire brushes or abrasive materials that could harm the chain's surface.

- Conduct frequent inspections: Check for signs of wear, corrosion, or broken links. Promptly replace any damaged or worn components to avoid further issues.

- Lubricate the chain consistently: Use a high-quality lubricant suitable for stainless steel chains. Apply it evenly to the chain surface and remove any excess oil with a clean cloth.

- Properly store the chain: When the chain is not in use, keep it in a dry and cool location to prevent corrosion and other environmental damage.

By adhering to these maintenance guidelines, you can prolong the lifespan of your D88C stainless steel pintle chain and ensure reliable performance. For additional information regarding our stainless steel pintle chains, please visit our website: https://netherlandsdrive.com/wp-content/uploads/2024/11/stainless-steel-pintle-chain-3.jpg

Sprockets for Stainless Steel Chains

When choosing the right sprocket for your D88C Stainless Steel Pintle Chain, several factors must be taken into account. The primary consideration is the number of teeth on the sprocket, which should align with the number of pitches in the chain for optimal compatibility. Additionally, ensure that the bore size of the sprocket fits the shaft diameter of the equipment in use.

Our company provides a diverse range of sprockets for sale, including those specifically designed for stainless steel chains. Our sprockets are crafted from high-quality materials and are available in various sizes and tooth counts to meet your specific requirements. We also offer custom sprocket manufacturing to accommodate unique specifications.

Explore our online selection of sprockets or contact us for more details on how we can assist you in finding the ideal sprocket for your D88C Stainless Steel Pintle Chain.

Why Choose Our Stainless Steel Pintle Chains?

Our D88C Stainless Steel Pintle Chain is a top-tier product that distinguishes itself from competitors. Constructed from high-quality stainless steel, our pintle chains guarantee durability and longevity, even in the harshest conditions. Each chain undergoes rigorous testing to ensure compliance with the highest quality and safety standards. Furthermore, our knowledgeable and experienced team provides outstanding customer service, ready to assist clients with any inquiries or concerns.

As the Holland sales representative for Ever-power Group, RP Techniek BV is dedicated to delivering the best possible products and services to our clientele. In addition to our stainless steel pintle chains, we also offer a wide selection of other stainless steel roller chains. With options designed for various applications and industries, we have solutions to meet diverse needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...