In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Dimensions of C63.5S-N1SS Stainless Steel Ice-cream Processing Chain

The C63.5S-N1SS Stainless Steel Ice-cream Processing Chain has the following parameters:

- Chain Pitch: 63.5mm

- Chain Thickness: 9.53mm

- Material: Stainless Steel

- Grade: N1SS

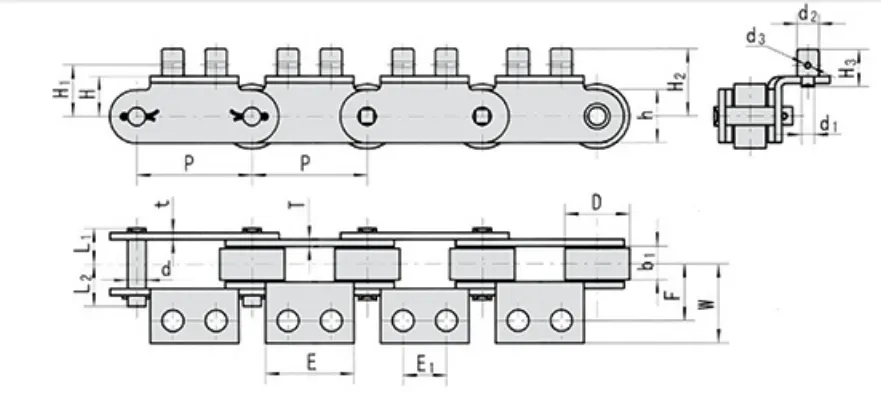

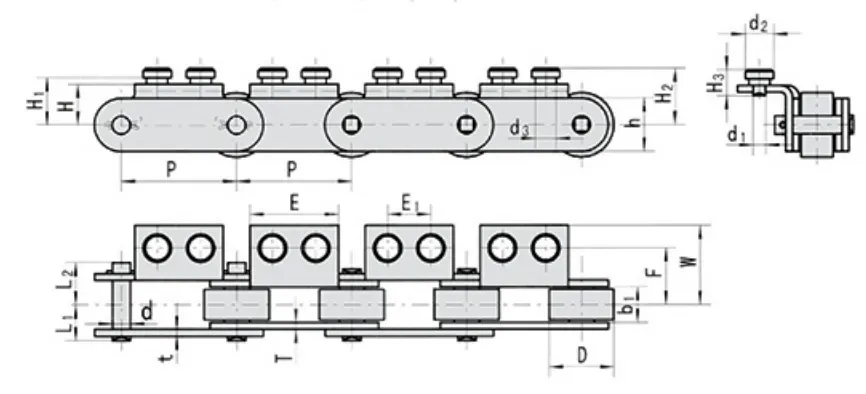

| E1 | E | F | W | H | H1 | H2 | H3 | d1 | d2 | d3 | ||

| Chain No | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Type |

| C216AL-K2ZB-RSS | 19.1 | 39 | 25.5 | 35.5 | 18 | 23 | 30 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C216AL-K2ZB-LSS | 19.1 | 39 | 25.5 | 35.5 | 18 | 21 | 25 | 11.5 | 6.6 | 12.5 | 9.3 | II |

| C216AL-SK2-N1SS | 19.05 | 39 | 28.18 | 38.73 | 19.05 | ¡ª¡ª | 31.75 | 17.2 | 6.6 | 9.5 | ¡ª¡ª | I |

| C216AL-SK2-N1SS | 19.05 | 39 | 28.18 | 38.73 | 19.05 | 22.05 | 26.05 | 11.5 | 6.6 | 12.5 | 9.3 | II |

| C63.5S-RSS | 25 | 47 | 25.5 | 36 | 24 | 29.5 | 36 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C63.5S-LSS | 25 | 47 | 25.5 | 36 | 24 | 27.5 | 31.5 | 12 | 6.6 | 12.5 | 9.3 | II |

| C63.5S-N2SS | 25 | 47 | 25.5 | 36 | 18 | 23.5 | 30 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C63.5S-N1SS | 25 | 47 | 25.5 | 36 | 18 | 21.5 | 25.5 | 12 | 6.6 | 12.5 | 9.3 | II |

| Chain No. |

Pitch | Width between inner plates |

Roller? diameter | Pin | Plate | UItimate tensile strength | Type | |||

| P | bl(min) | D(max) | d | L1 | L2 | h | t/T | Q(min) | ||

| mm | mm | mm | mm | mm | mm | mm | mm | KN | ||

| C216AL-K2ZB-RSS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | I |

| C216AL-K2ZB-LSS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | II |

| C216AL-SK2-N1SS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | I |

| C216AL-SK2-N1SS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | II |

| C63.5S-RSS | 63.5 | 15.75 | 39.68 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | I |

| C63.5S-LSS | 63.5 | 15.75 | 39.68 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | II |

| C63.5S-N2SS | 63.5 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | I |

| C63.5S-N1SS | 63.5 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | II |

1: Introduction

Welcome to the world of C63.5S-N1SS Stainless Steel Ice-cream Processing Chain, where innovation meets excellence. Our cutting-edge chain is specifically designed for the ice-cream industry, offering unmatched quality and performance. With our chain, you can elevate your production process to new heights, ensuring efficient and seamless ice-cream manufacturing.

2: Superior Durability

Our C63.5S-N1SS Stainless Steel Ice-cream Processing Chain is built to withstand the most demanding environments. Crafted from premium stainless steel, it exhibits exceptional strength and resistance to corrosion, ensuring longevity and reliability. Say goodbye to chain breakages and costly replacements, as our chain is built to endure even the harshest conditions.

3: Optimum Efficiency

Designed with precision engineering, our chain guarantees optimal performance in ice-cream processing. Its innovative design minimizes friction, allowing smooth and efficient movement throughout the production line. This reduces energy consumption and maximizes productivity, ultimately leading to higher output and cost savings.

4: Hygienic Excellence

Hygiene is of utmost importance in the food industry, and our C63.5S-N1SS Stainless Steel Ice-cream Processing Chain ensures uncompromising cleanliness. With its seamless construction and smooth surface finish, it prevents the accumulation of debris and bacteria, facilitating easy cleaning and maintenance. Rest assured that our chain meets the highest standards of food safety and hygiene.

5: Customization Options

We understand that every ice-cream processing facility has unique requirements. That's why our C63.5S-N1SS Stainless Steel Ice-cream Processing Chain offers a range of customization options. From length to width, pitch to attachments, we can tailor the chain to fit your specific needs. Our team of experts is ready to work closely with you to design a chain that optimizes your production process.

Experience the revolution in ice-cream processing with the C63.5S-N1SS Stainless Steel Ice-cream Processing Chain. Contact us today to discover how our chain can elevate your ice-cream manufacturing to new levels of excellence.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. Our company offers a wide range of superior quality stainless steel roller chains, including the C63.5S-N1SS Stainless Steel Ice-cream Processing Chain. Our unique selling point is our commitment to providing high-quality products and excellent customer service.

Our stainless steel roller chains are designed to provide optimal performance and durability. They are resistant to corrosion, high temperatures, and chemical exposure, making them ideal for use in harsh environments. Our chains are also easy to install and require minimal maintenance, ensuring that they consistently operate at their best.

Our production capability is another advantage that sets us apart from the competition. We have state-of-the-art manufacturing facilities and a team of experienced professionals that ensure our products meet the highest standards of quality and precision.

In addition to the C63.5S-N1SS Stainless Steel Ice-cream Processing Chain, we also offer a wide range of other stainless steel roller chains for sale. Our products are suitable for various applications, including food processing, agriculture, and industrial manufacturing.

Sprockets for Sale

When it comes to the C63.5S-N1SS Stainless Steel Ice-cream Processing Chain, we offer a wide range of suitable sprockets to ensure optimal performance. Our company specializes in providing various types of sprockets that cater to different needs and requirements.

Whether you are looking for standard sprockets, custom-made sprockets, or specialized sprockets for specific applications, we have got you covered. Our sprockets are designed with precision and manufactured using high-quality materials to ensure durability and long-lasting performance.

With our extensive selection of sprockets, you can find the perfect match for your C63.5S-N1SS Stainless Steel Ice-cream Processing Chain. We offer sprockets with different teeth counts, pitch sizes, and bore diameters to meet your specific needs.

At our company, we understand the importance of reliable and efficient chain and sprocket systems in various industries. That is why we strive to provide top-notch sprockets that deliver excellent functionality and enhance the overall performance of your equipment.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...