Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

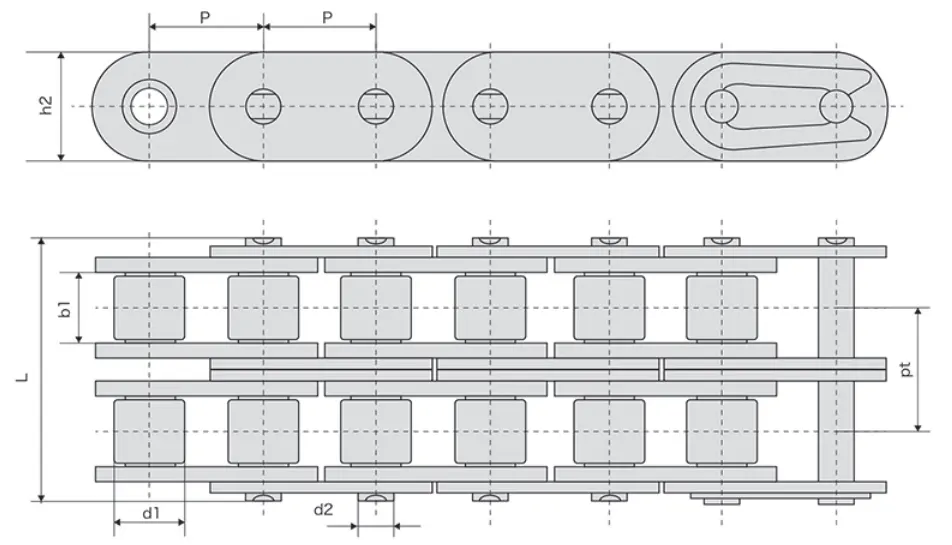

Specifications of C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates

- Chain Series: C40SS-2

- Material: Duplex Stainless Steel

- Side Plates: Straight

- Maximum Allowable Load: 5,400 lbs

- Pitch Size: 0.5 inch

- Roller Diameter: 0.3125 inch

- Plate Height: 0.591 inch

- Plate Thickness: 0.078 inch

- Pin Diameter: 0.156 inch

- Overall Width: 0.992 inch

- Average Tensile Strength: 11,200 lbs

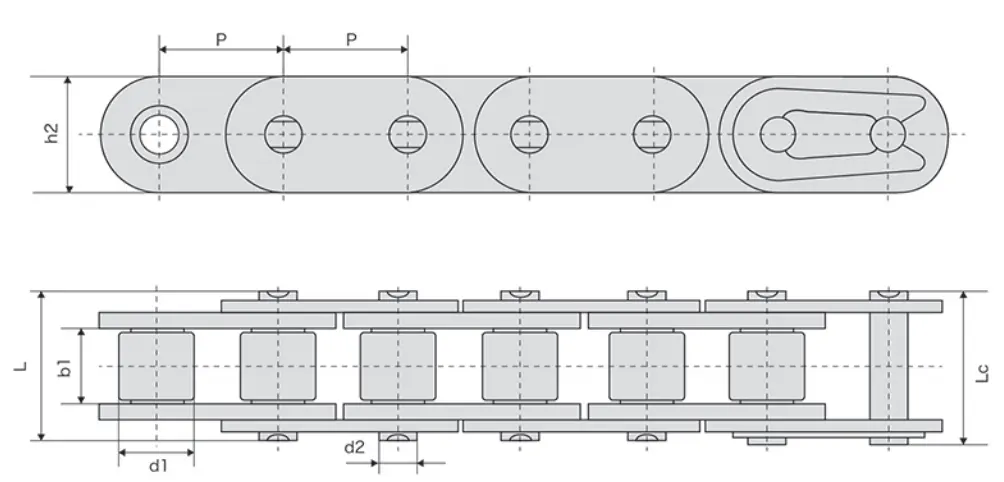

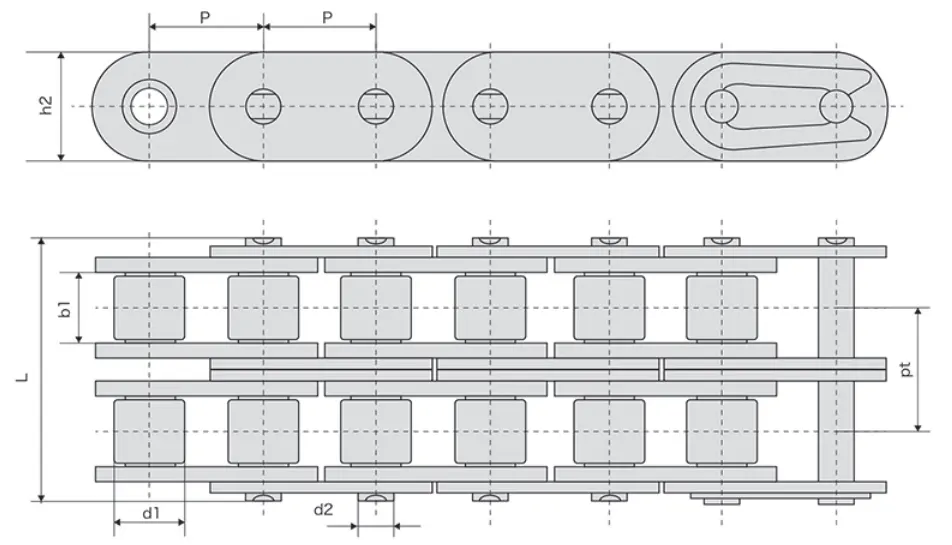

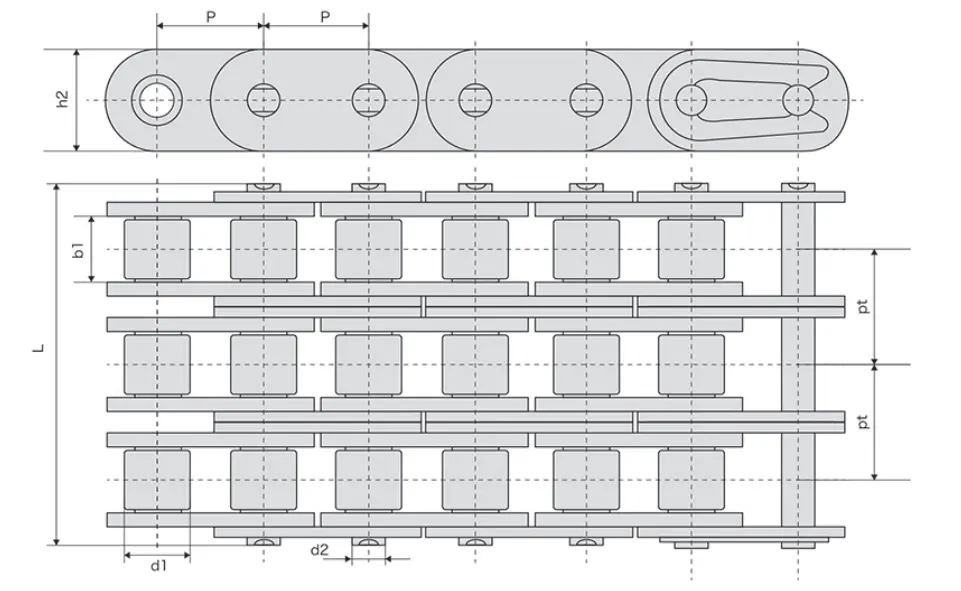

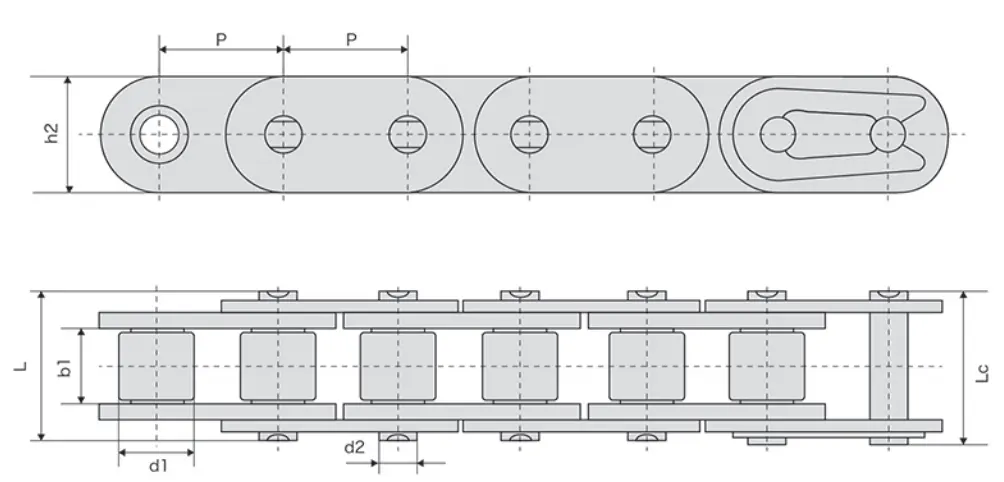

| DIN ISO Chain No. | DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

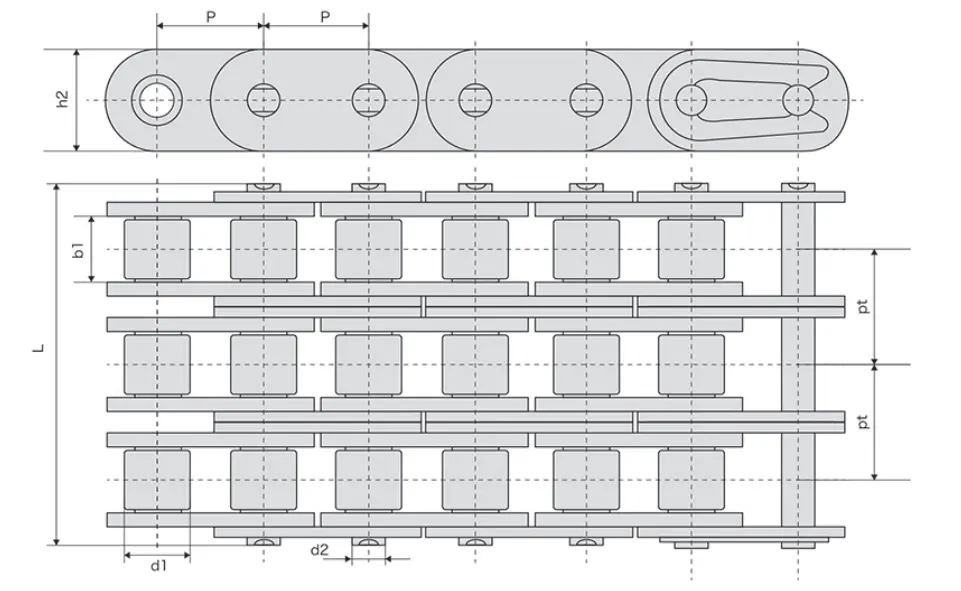

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Pt | Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Introduction

The C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a high-performance roller chain that is designed to provide excellent corrosion resistance and durability in harsh environments. Made from high-quality duplex stainless steel, this roller chain is ideal for applications that require high strength and resistance to corrosion and wear.

Features and Benefits

- High-strength: The C40SS-2 roller chain is made from high-quality duplex stainless steel, which provides excellent strength and durability.

- Corrosion resistance: Duplex stainless steel is highly resistant to corrosion, making this roller chain ideal for use in harsh environments.

- Wear resistance: The straight side plates of the C40SS-2 roller chain provide excellent wear resistance, ensuring a longer service life.

- Wide temperature range: This roller chain can operate in temperatures ranging from -40¡ãC to +230¡ãC, making it suitable for use in a variety of applications.

- Low maintenance: The C40SS-2 roller chain requires minimal maintenance, reducing downtime and increasing productivity.

Applications

The C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is suitable for use in a variety of applications, including:

- Food and beverage processing

- Marine and offshore environments

- Chemical processing

- Mining and quarrying

- Pulp and paper mills

- Wastewater treatment plants

Technical Specifications

| Chain Size | Pitch | Ultimate Strength | Weight per Meter |

|---|---|---|---|

| C40SS-2 | 1/2 inch | 31.2 kN | 2.9 kg/m |

Installation and Maintenance

Proper installation and maintenance of the C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is essential for ensuring optimal performance and maximum service life. Before installation, inspect the chain for any damage or defects, and ensure that it is properly lubricated. During operation, regularly inspect the chain for wear and lubricate as needed. When replacing the chain, be sure to use a chain of the same size and type.

Conclusion

The C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality roller chain that is designed to provide excellent performance in harsh environments. With its high strength, corrosion resistance, and wear resistance, this roller chain is ideal for a wide range of applications, from food and beverage processing to marine and offshore environments. Proper installation and maintenance are essential for ensuring optimal performance and maximum service life.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the authorized sales representative of Ever-power Group in the Netherlands. Our company offers a wide range of stainless steel roller chains, including the exceptional C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates.

Our chains stand out in terms of their superior quality and durability, ensuring reliable performance in harsh operating conditions. Moreover, we pride ourselves on delivering exceptional customer service, ensuring that our clients receive the right product for their applications.

At RP Techniek BV, we have a state-of-the-art production facility that utilizes the latest manufacturing technologies and equipment. This enables us to produce high-quality stainless steel roller chains that meet and exceed our clients' expectations.

Apart from C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, we offer various other types of stainless steel roller chains for sale. You can count on us to provide you with the right chain that suits your specific requirements.

Choose RP Techniek BV for your stainless steel roller chain needs, and experience unmatched quality and service.

Sprockets for Sale

When it comes to the C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, we have the perfect sprocket options to complement it. Our company offers a wide range of different types of sprockets for sale.

Our sprockets are designed with precision to ensure optimal performance and durability. Whether you need a smaller sprocket for high-speed applications or a larger one for heavy-duty operations, we have got you covered. Our sprockets are made from high-quality materials, including stainless steel, which makes them resistant to corrosion and wear.

With our extensive selection, you can find the right sprocket to match your specific needs. We offer various tooth counts and sizes to accommodate different chain configurations. Our sprockets are compatible with the C40SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, ensuring a reliable and efficient power transmission system.

Take a look at the image below to get a visual representation of our sprocket options:

For more information or to place an order, please contact us. We are here to assist you in finding the perfect sprocket solution for your application.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...