Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications of C40SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates

- Chain Size: C40SS-1

- Material: Stainless Steel

- Plate Type: Straight

- Number of Strands: 1

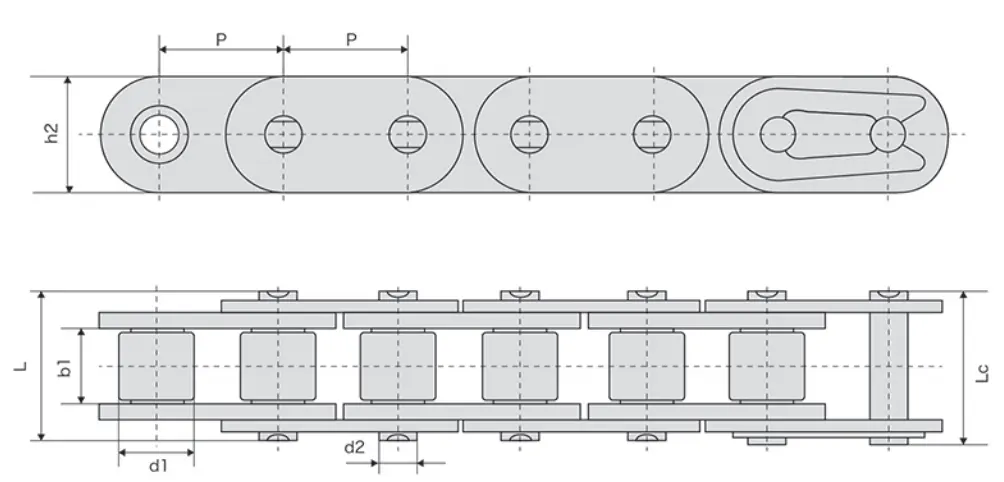

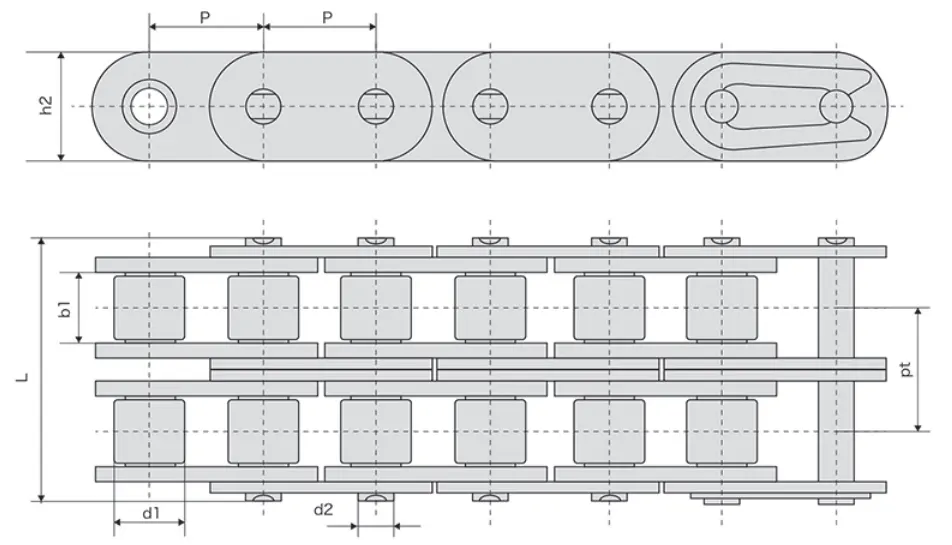

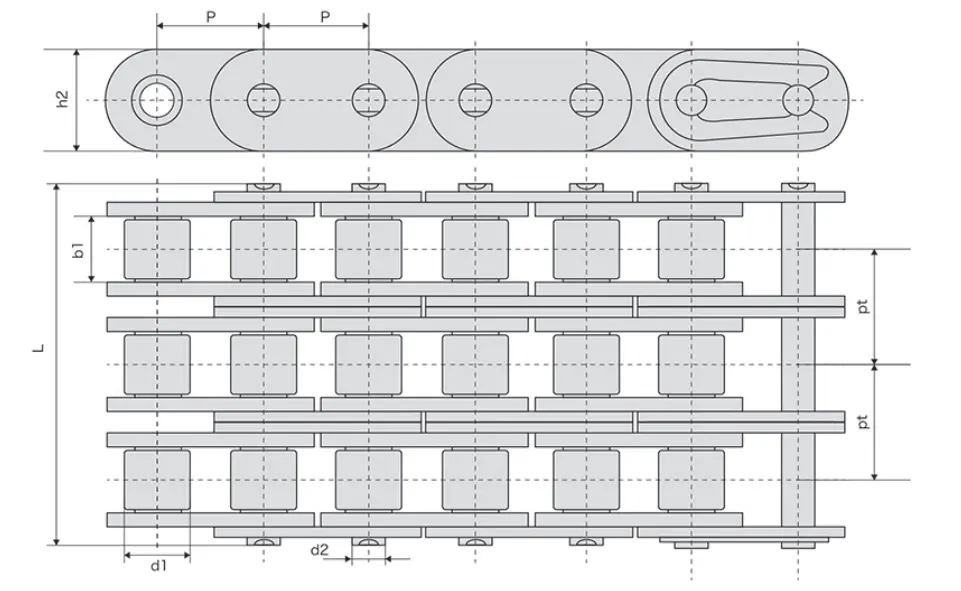

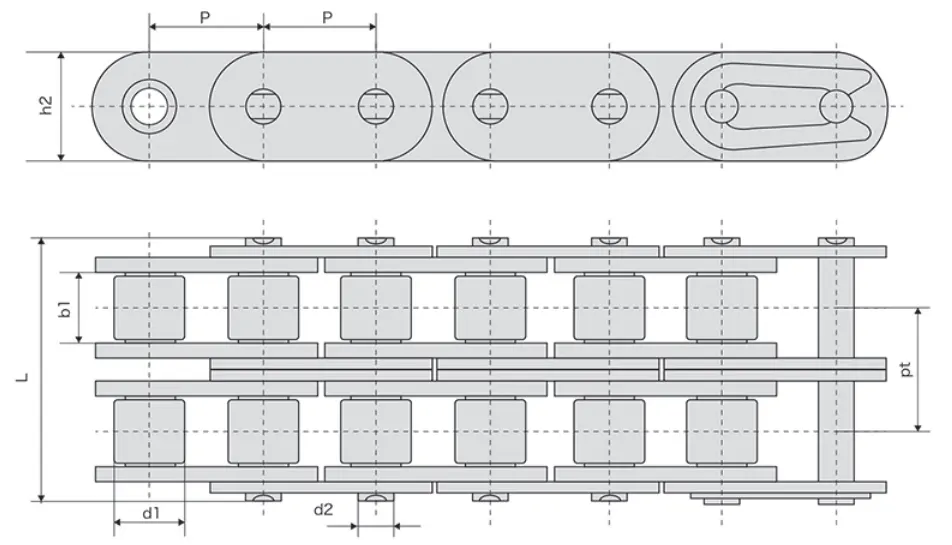

| DIN ISO Chain No. | DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

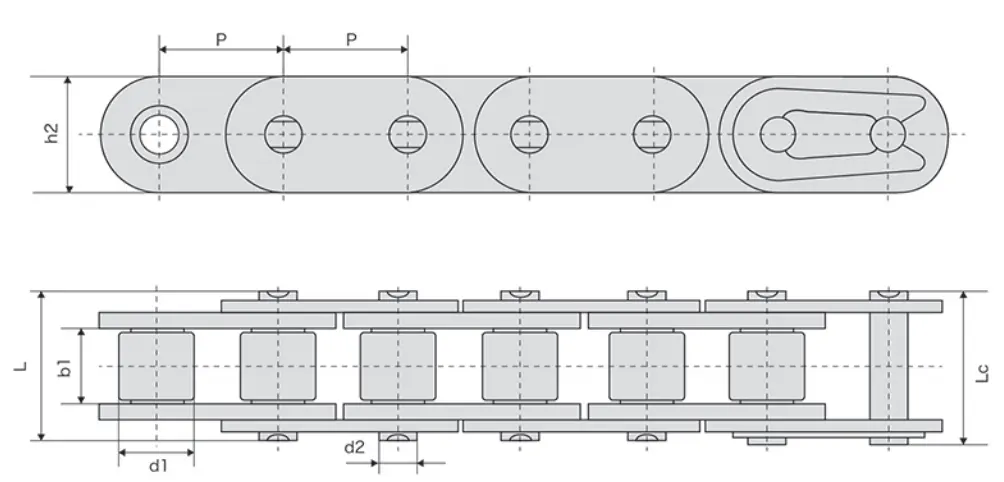

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

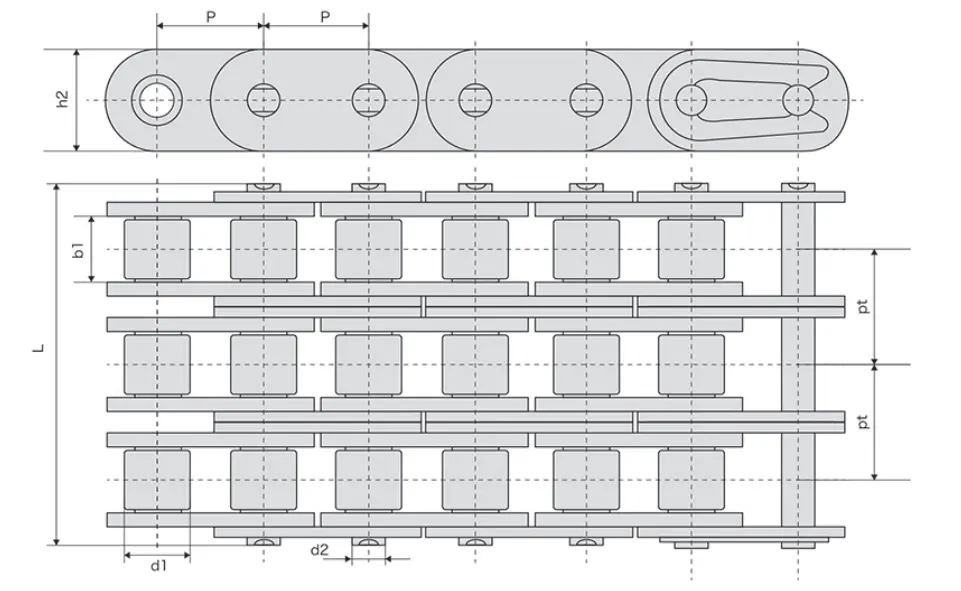

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Pt | Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Introduction

Welcome to the product knowledge introduction of C40SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates. In this article, we will explore the features and benefits of this exceptional roller chain, designed to meet the highest standards in various industries. Let's dive into the details!

1. Superior Durability and Corrosion Resistance

The C40SS-1 roller chain is constructed using top-quality stainless steel, ensuring remarkable durability and corrosion resistance. This chain is optimized for applications in harsh environments, such as marine, food processing, and chemical industries. The stainless steel material provides excellent protection against rust, making it ideal for challenging operating conditions.

2. Straight Side Plates for Enhanced Performance

One of the standout features of the C40SS-1 roller chain is its straight side plates. This design optimizes the chain's performance by providing smooth engagement with sprockets and minimizing the risk of chain derailing. With straight side plates, the chain operates with increased efficiency, reducing wear and tear and prolonging the overall lifespan of the chain.

2.1 Enhanced Load Capacity

The straight side plates of the C40SS-1 roller chain also contribute to its enhanced load capacity. This feature allows the chain to handle heavier loads, making it suitable for demanding applications. Whether it's transmitting power or conveying materials, this chain is built to withstand high tension and deliver reliable performance even under extreme conditions.

3. Precise Manufacturing and Tight Tolerance

The C40SS-1 roller chain is precision-manufactured with tight tolerances, ensuring consistent and reliable performance. Each component is meticulously crafted to fit together seamlessly, providing smooth and efficient power transmission. The precise manufacturing process guarantees minimal elongation and extends the chain's life, reducing the need for frequent replacements.

4. Wide Range of Applications

Thanks to its exceptional durability and performance, the C40SS-1 roller chain finds applications in various industries. Some common uses include conveyor systems, packaging machinery, agricultural equipment, and industrial automation. Whether it's moving heavy loads or driving complex machinery, this roller chain is a reliable choice.

5. Easy Installation and Maintenance

The C40SS-1 roller chain is designed for easy installation and maintenance. Its standardized dimensions and clear assembly instructions simplify the installation process, saving valuable time and effort. Additionally, periodic lubrication and regular inspection are all that's needed to keep this chain operating smoothly, ensuring minimal downtime and maximizing productivity.

Conclusion

The C40SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates stands out as a superior choice for demanding applications. With its durability, corrosion resistance, enhanced performance, and easy maintenance, this roller chain offers exceptional value for a wide range of industries. Invest in the C40SS-1 roller chain today and experience the difference it makes in your operations!

Choose Our Stainless Steel Roller Chains

RP Techniek BV, the Netherlands sales agent of Ever-power Group, is proud to offer the C40SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates. This chain showcases our unique selling points, highlighting the exceptional quality and service we provide. With our robust manufacturing capabilities, we ensure that our products meet the highest standards.

In addition to the C40SS-1, we offer a wide range of other stainless steel roller chains for sale. Our diverse selection caters to various needs and applications. Whether you require chains for industrial machinery or automotive systems, we have you covered.

At RP Techniek BV, we understand the importance of reliability and durability. That's why our stainless steel roller chains are designed to withstand demanding environments and deliver optimal performance. Trust us to provide you with the superior products you need.

To learn more about our stainless steel roller chains and explore our extensive product line, please visit our website. Don't miss out on the opportunity to enhance your operations with our top-quality chains.

Sprockets for Sale

When it comes to finding the right chain and sprocket combination for your industrial application, it's important to choose quality components that can withstand the demands of your operation. The C40SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates is one of our recommended chains that pairs well with our various sprockets.

At our company, we offer a wide selection of sprockets to accommodate different chain sizes, tooth counts, and materials. Whether you need a standard carbon steel sprocket or a specialized, high-performance stainless steel sprocket, we have options to suit your needs. We also provide custom sprocket machining services that allow us to create bespoke sprockets to your exact specifications.

With our extensive inventory and competitive prices, you can trust us to supply the right sprocket for your application. Contact us to learn more about our selection of sprockets and other power transmission components.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...