In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

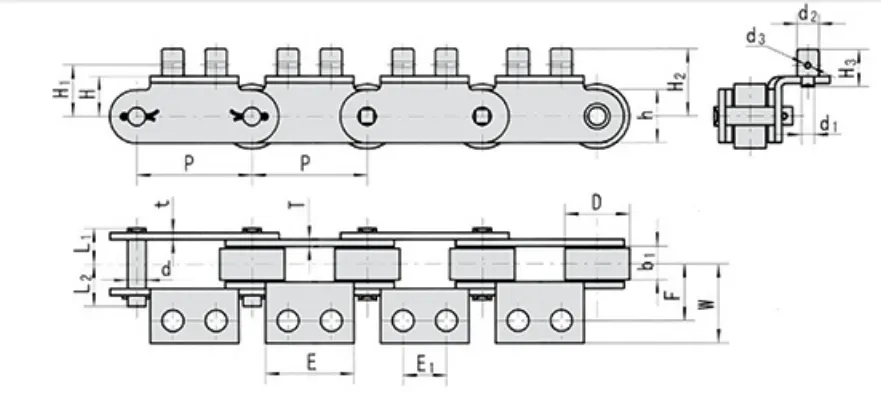

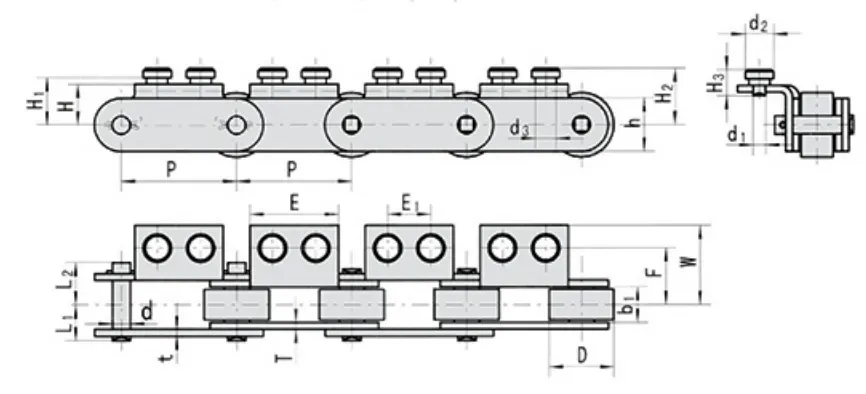

Dimensions of C216AL-SK2-N1SS Stainless Steel Ice-cream Processing Chain

Below are the parameters of the C216AL-SK2-N1SS Stainless Steel Ice-cream Processing Chain:

- Material: Stainless steel

- Model: C216AL-SK2-N1SS

- Chain Pitch: 1.5 inch

- Width: 0.88 inch

- Height: 1.23 inch

- Weight per foot: 2.46 pounds

- Maximum allowable load: 6,000 pounds

| E1 | E | F | W | H | H1 | H2 | H3 | d1 | d2 | d3 | ||

| Chain No | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | Type |

| C216AL-K2ZB-RSS | 19.1 | 39 | 25.5 | 35.5 | 18 | 23 | 30 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C216AL-K2ZB-LSS | 19.1 | 39 | 25.5 | 35.5 | 18 | 21 | 25 | 11.5 | 6.6 | 12.5 | 9.3 | II |

| C216AL-SK2-N1SS | 19.05 | 39 | 28.18 | 38.73 | 19.05 | ¡ª¡ª | 31.75 | 17.2 | 6.6 | 9.5 | ¡ª¡ª | I |

| C216AL-SK2-N1SS | 19.05 | 39 | 28.18 | 38.73 | 19.05 | 22.05 | 26.05 | 11.5 | 6.6 | 12.5 | 9.3 | II |

| C63.5S-RSS | 25 | 47 | 25.5 | 36 | 24 | 29.5 | 36 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C63.5S-LSS | 25 | 47 | 25.5 | 36 | 24 | 27.5 | 31.5 | 12 | 6.6 | 12.5 | 9.3 | II |

| C63.5S-N2SS | 25 | 47 | 25.5 | 36 | 18 | 23.5 | 30 | 16.5 | 6.6 | 9.5 | 2.5 | I |

| C63.5S-N1SS | 25 | 47 | 25.5 | 36 | 18 | 21.5 | 25.5 | 12 | 6.6 | 12.5 | 9.3 | II |

| Chain No. |

Pitch | Width between inner plates |

Roller? diameter | Pin | Plate | UItimate tensile strength | Type | |||

| P | bl(min) | D(max) | d | L1 | L2 | h | t/T | Q(min) | ||

| mm | mm | mm | mm | mm | mm | mm | mm | KN | ||

| C216AL-K2ZB-RSS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | I |

| C216AL-K2ZB-LSS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | II |

| C216AL-SK2-N1SS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | I |

| C216AL-SK2-N1SS | 50.8 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.6 | 3 | 40 | II |

| C63.5S-RSS | 63.5 | 15.75 | 39.68 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | I |

| C63.5S-LSS | 63.5 | 15.75 | 39.68 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | II |

| C63.5S-N2SS | 63.5 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | I |

| C63.5S-N1SS | 63.5 | 15.75 | 28.58 | 7.92 | 16.35 | 18.85 | 23.5 | 3 | 40 | II |

1: Introduction

In this article, we will explore the innovative C216AL-SK2-N1SS Stainless Steel Ice-cream Processing Chain. This high-quality chain is specifically designed to meet the unique demands of ice-cream processing, providing exceptional reliability, durability, and efficiency.

2: Superior Stainless Steel Construction

With its superior stainless steel construction, the C216AL-SK2-N1SS chain offers outstanding resistance to corrosion, heat, and wear. The use of high-quality stainless steel ensures the longevity of the chain, making it ideal for the rigorous demands of ice-cream processing.

3: Advanced Lubrication System

The C216AL-SK2-N1SS chain is equipped with an advanced lubrication system that ensures smooth operation even in extreme conditions. This system reduces friction, minimizes wear and tear, and extends the lifespan of the chain, resulting in improved efficiency and reduced maintenance costs.

4: Enhanced Design for Optimal Performance

Designed with precision engineering, the C216AL-SK2-N1SS chain features specially designed attachments that maximize its performance in ice-cream processing applications. The unique design reduces product contamination risks, ensures consistent product quality, and enhances overall productivity.

5: Customizable Options

The C216AL-SK2-N1SS chain offers a range of customizable options to meet specific processing requirements. From different chain lengths to various attachment configurations, this chain can be tailored to fit different ice-cream processing machines, providing flexibility and versatility to manufacturers.

In conclusion, the C216AL-SK2-N1SS Stainless Steel Ice-cream Processing Chain is a reliable, durable, and efficient solution for the demanding needs of ice-cream processing. With its superior stainless steel construction, advanced lubrication system, enhanced design, and customizable options, this chain provides manufacturers with the confidence and performance they need to optimize their production processes.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official Netherlands sales agent for Ever-power Group. Our company takes pride in offering only the best products and services to our clients. One of our unique selling points is the C216AL-SK2-N1SS Stainless Steel Ice-cream Processing Chain, which is known for its exceptional quality and durability.

This chain is made of high-quality stainless steel, making it resistant to corrosion, heat, and wear. It is specifically designed for ice-cream processing applications, making it the perfect chain for use in the food industry. In addition, we offer a wide range of other types of stainless steel roller chains for sale.

At RP Techniek BV, we are committed to providing our clients with the best possible products and services. We have a team of experienced professionals who are dedicated to ensuring that every chain we sell meets our high standards for quality and reliability. We also have state-of-the-art production facilities that allow us to produce chains of the highest quality in large quantities.

We believe that our commitment to quality and our focus on customer satisfaction sets us apart from our competitors. If you are in need of a high-quality stainless steel roller chain, then look no further than RP Techniek BV.

Sprockets for Sale

For the C216AL-SK2-N1SS Stainless Steel Ice-cream Processing Chain, we recommend using a matching sprocket made from high-quality stainless steel for optimal performance and durability. Our company offers a wide variety of sprockets for sale, including a range of tooth counts and sizes to fit your specific needs.

All of our sprockets are manufactured using top-grade materials and precise machining techniques to ensure the highest level of accuracy and reliability. We also offer custom sprocket designs to meet your unique requirements.

Whether you need a standard sprocket or a custom solution, our team of experts can help you find the perfect product to maximize the performance of your machinery.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...