Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

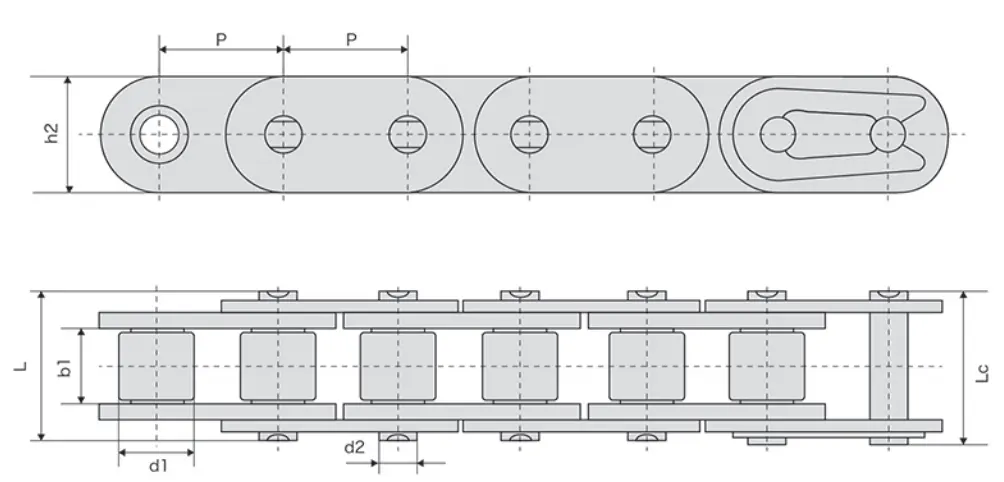

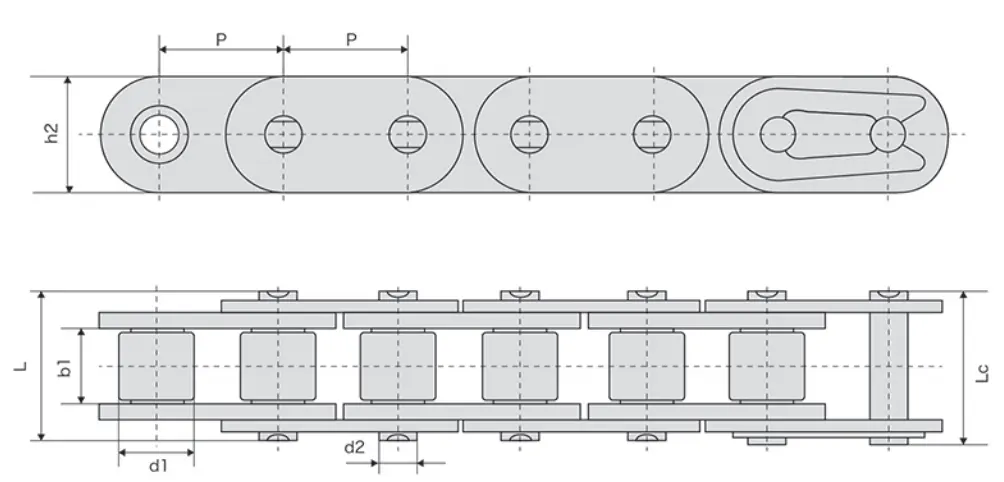

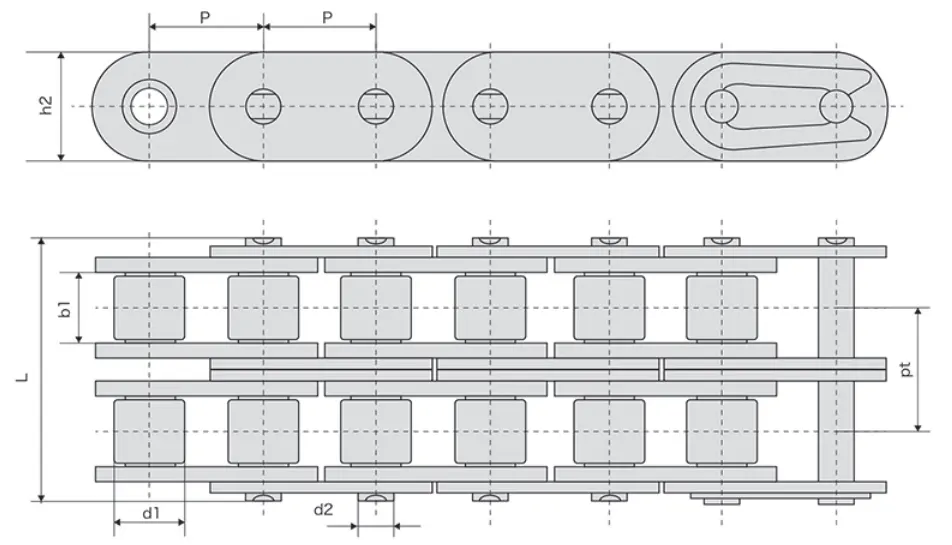

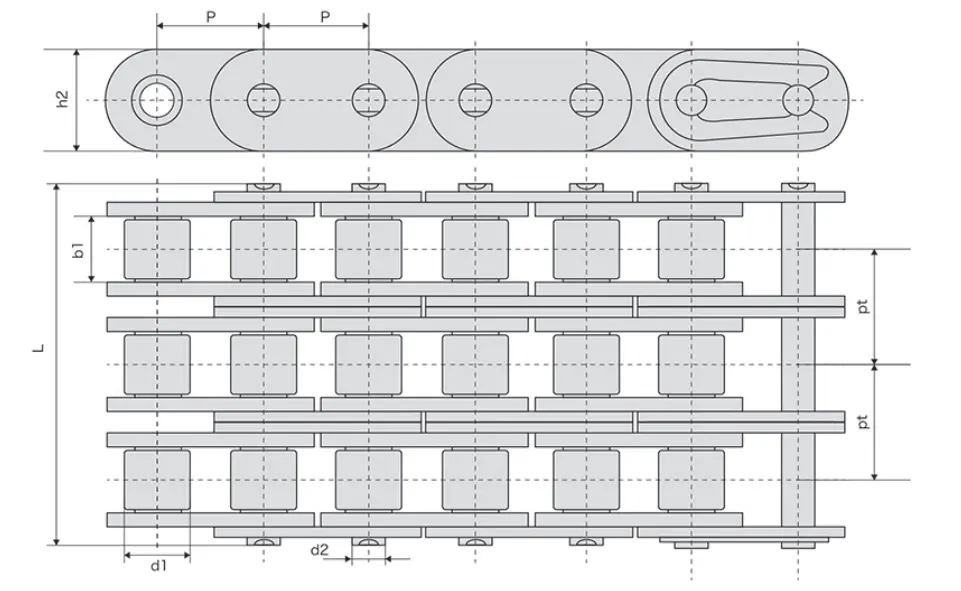

The C12BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates has the following parameters:

| DIN ISO Chain No. | DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

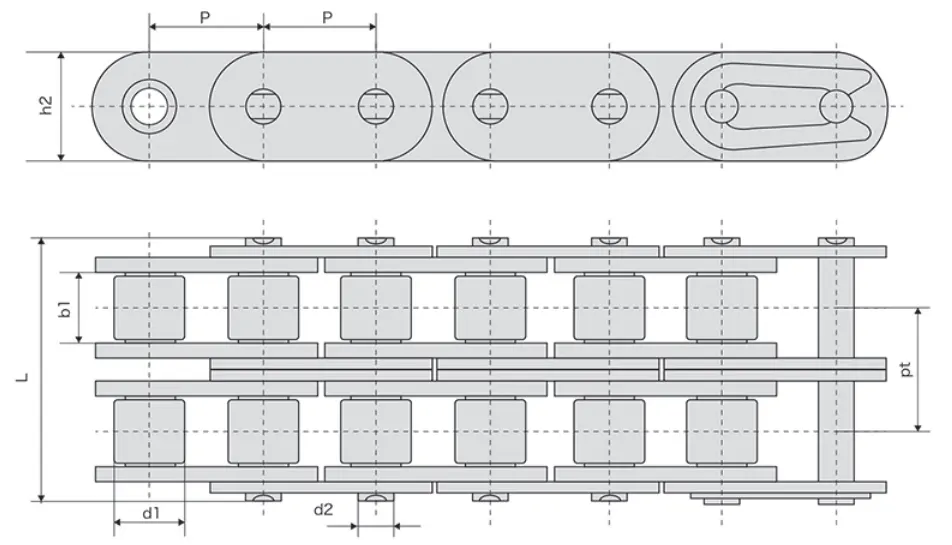

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Pt | Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

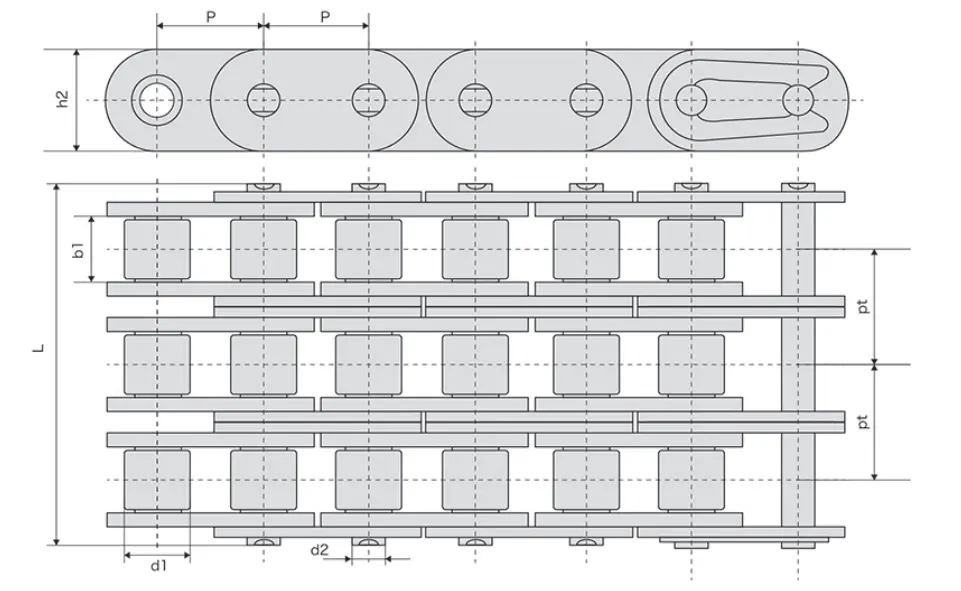

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Title 1: Introduction to C12BSS-2 Duplex Stainless Steel Roller Chain

In this section, we will provide a comprehensive overview of the C12BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates. This high-quality roller chain is designed specifically for applications that require corrosion resistance and superior strength.

Title 2: Key Features of C12BSS-2 Duplex Stainless Steel Roller Chain

Corrosion Resistance

The C12BSS-2 Duplex Stainless Steel Roller Chain is constructed using a special grade of duplex stainless steel, which provides exceptional resistance to corrosion in harsh environments. This makes it an ideal choice for industries such as marine, chemical processing, and food production.

High Strength

With its straight side plates made from duplex stainless steel, this roller chain offers remarkable strength and durability. It can withstand heavy loads and operate smoothly even in demanding conditions, ensuring reliable performance and minimal downtime.

Extended Service Life

Thanks to its robust construction and corrosion-resistant properties, the C12BSS-2 Duplex Stainless Steel Roller Chain has an extended service life compared to traditional roller chains. This helps reduce maintenance costs and improves overall productivity.

Wide Temperature Range

Designed to withstand extreme temperature variations, this roller chain is suitable for both high-temperature and low-temperature applications. It maintains its integrity and performance, ensuring consistent operation even in challenging environmental conditions.

Easy Installation and Maintenance

The C12BSS-2 Duplex Stainless Steel Roller Chain is engineered for easy installation and maintenance. Its design allows for quick assembly and disassembly, minimizing downtime and keeping production processes running smoothly.

Title 3: Applications of C12BSS-2 Duplex Stainless Steel Roller Chain

In this section, we will explore the various industries and applications that can benefit from the use of the C12BSS-2 Duplex Stainless Steel Roller Chain.

Marine Industry

This roller chain is widely used in marine applications, such as shipbuilding, offshore oil rigs, and fishing equipment. Its corrosion resistance and high strength make it suitable for withstanding the harsh conditions of saltwater environments.

Chemical Processing

In chemical processing plants, where exposure to corrosive chemicals is common, the C12BSS-2 Duplex Stainless Steel Roller Chain excels. Its resistance to chemical corrosion ensures reliable operation and minimizes the risk of chain failure.

Food Production

Food production facilities require equipment that meets stringent hygiene standards. This roller chain is an excellent choice for conveyors and other machinery used in food processing, as it is easy to clean and resistant to food acids and contaminants.

Automotive Industry

The automotive industry relies on durable and reliable components. The C12BSS-2 Duplex Stainless Steel Roller Chain is suitable for various automotive applications, including engine timing systems and power transmission, due to its high strength and resistance to wear and tear.

Packaging Machinery

With its ability to handle heavy loads and operate smoothly, this roller chain is commonly used in packaging machinery. It ensures efficient and reliable movement of conveyor belts, ensuring optimal productivity in packaging processes.

Title 4: Installation and Maintenance Guidelines

To ensure optimal performance and longevity of the C12BSS-2 Duplex Stainless Steel Roller Chain, proper installation and maintenance procedures should be followed. Here are some guidelines:

Installation

- Ensure the chain is properly aligned with the sprockets before installation.

- Lubricate the chain with a suitable lubricant to minimize friction and wear.

- Check the tension of the chain regularly and adjust if necessary to prevent excessive slack or tightness.

Maintenance

- Regularly inspect the chain for signs of wear, corrosion, or damage.

- Clean the chain using a mild detergent and water to remove dirt and debris.

- Apply lubrication as recommended by the manufacturer to maintain smooth operation.

Title 5: Conclusion

The C12BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a reliable and durable solution for industries that require corrosion resistance and high strength. Its exceptional performance, extended service life, and ease of installation make it a valuable asset in various applications. Invest in this roller chain to enhance productivity and reduce downtime in your operations.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the authorized sales agent for Ever-power Group in the Netherlands. Our C12BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a unique product that showcases our company's commitment to quality and service. We take pride in providing our customers with durable, reliable chains that are built to last.

Our stainless steel roller chains are manufactured to the highest standards using top-quality materials and state-of-the-art production techniques. Our chains are designed to withstand even the harshest environments, making them the ideal choice for a wide range of applications.

In addition to our C12BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, we offer a variety of other types of stainless steel roller chains for sale. Whatever your needs may be, we have a chain that is sure to meet them.

At RP Techniek BV, we are committed to providing our customers with the highest level of service and support. Our experienced team of professionals is always on hand to answer any questions you may have and to help you find the perfect chain for your needs.

Choose RP Techniek BV for all your stainless steel roller chain needs and experience the difference that quality and service can make.

Sprockets for Sale

If you are looking for the perfect sprocket to pair with your C12BSS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, look no further than our extensive selection of sprockets. Our company offers a wide variety of sprockets to meet the needs of any application, from agricultural machinery to heavy-duty industrial equipment.

All of our sprockets are made from high-quality materials and are designed to provide long-lasting performance. In addition to our standard sprockets, we also offer custom sprockets to meet the unique needs of our customers.

Whether you need a simple stock sprocket or a custom solution, our team of experts is here to help. We are committed to providing our customers with the best possible service and will work with you to find the perfect sprocket for your needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...