In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

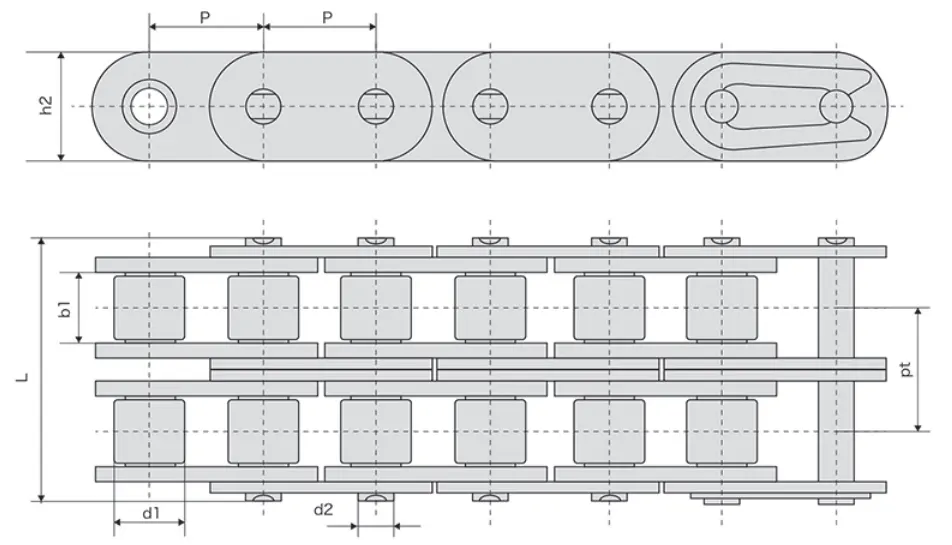

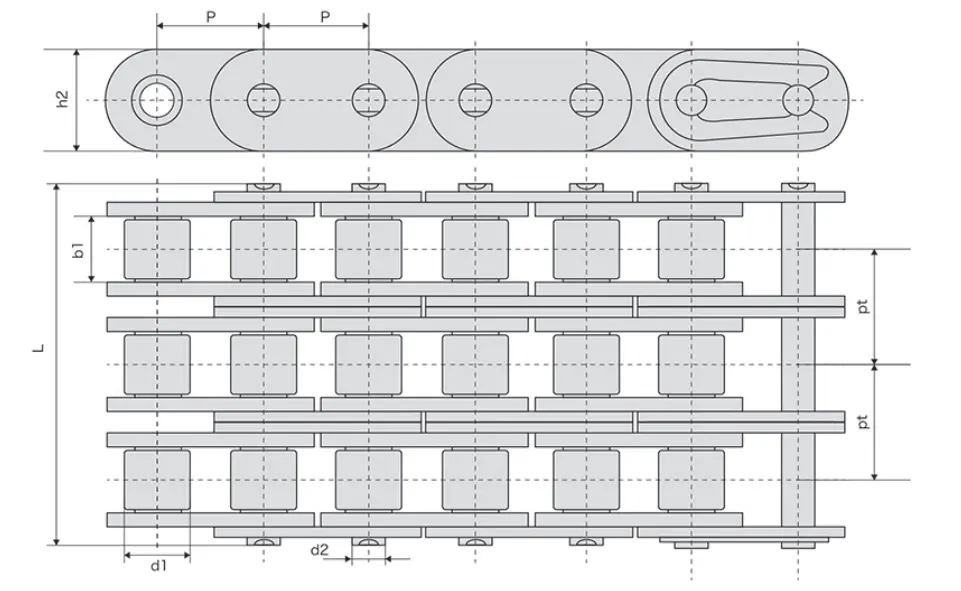

Specifications for C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates

- Chain Size: C100SS-2

- Material: Duplex Stainless Steel

- Plate Type: Straight

- Roller Type: Standard

- Pin Type: Riveted

- Maximum Allowable Load: 10,000 lbs

- Maximum Allowable Speed: 2,000 RPM

- Connecting Link: Included

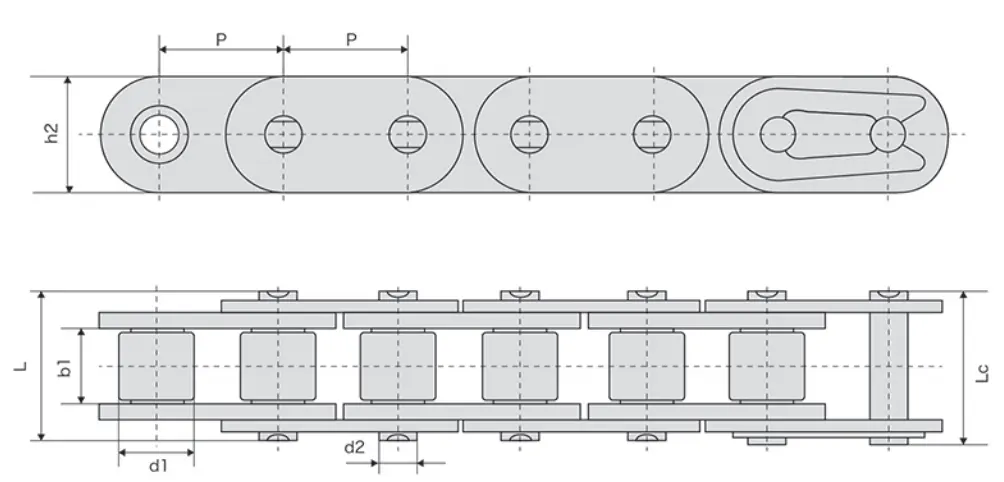

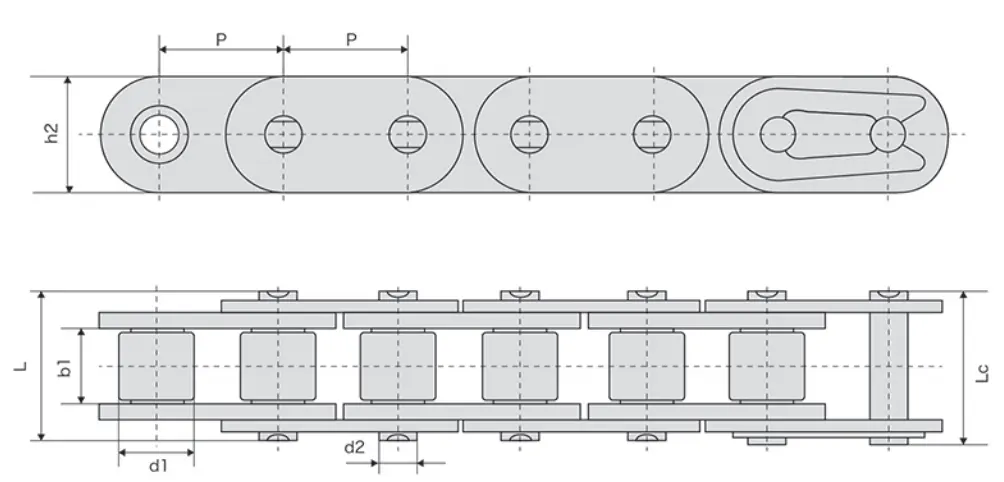

| DIN ISO Chain No. | DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

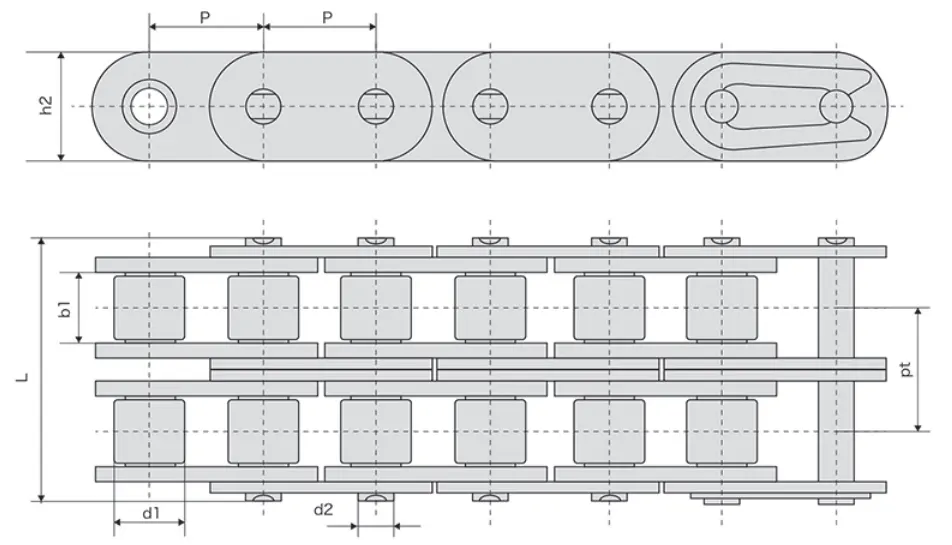

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

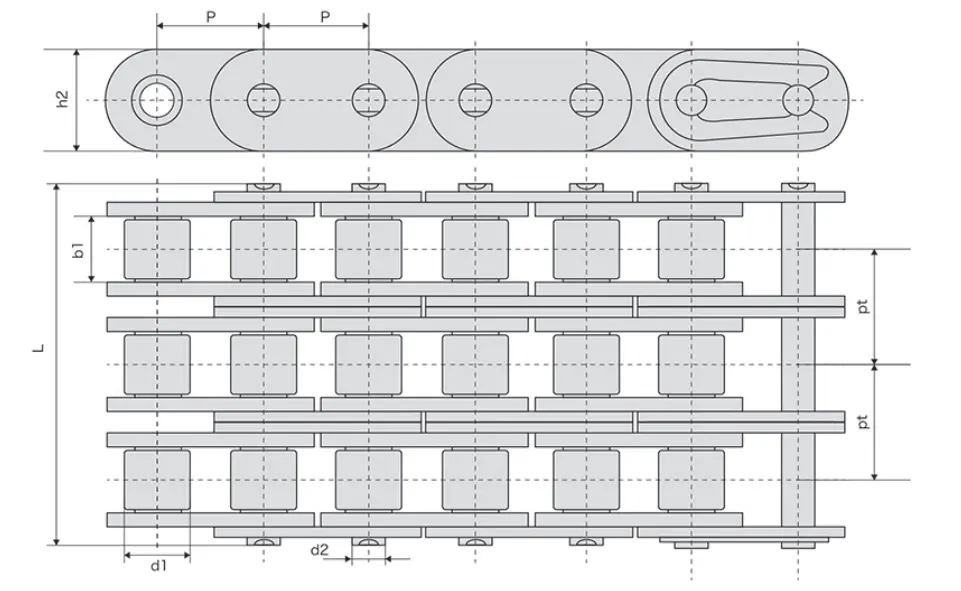

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Pt | Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Introduction

The C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality roller chain that is designed for use in demanding applications that require high strength and corrosion resistance. This roller chain is made from duplex stainless steel, which is a type of stainless steel that has a two-phase microstructure consisting of both austenitic and ferritic phases. This unique microstructure provides the chain with superior strength and corrosion resistance, making it ideal for use in harsh environments.

Features

1. High Strength

The C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is designed to provide high tensile strength, making it ideal for use in applications that require heavy loads and high stress. The duplex stainless steel material provides the chain with excellent strength and durability, ensuring that it can withstand even the most demanding conditions.

2. Corrosion Resistance

The duplex stainless steel material used in the C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates provides excellent resistance to corrosion, making it ideal for use in environments where exposure to harsh chemicals and saltwater is common. The chain is also resistant to stress corrosion cracking, which is a common problem in many other types of roller chains.

3. Extended Service Life

The C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is designed to provide an extended service life, even in harsh environments. The superior strength and corrosion resistance of the chain help to prevent premature wear and failure, ensuring that the chain can provide reliable performance for many years.

4. Easy Maintenance

The C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is designed for easy maintenance, with simple lubrication and cleaning requirements. The chain is also resistant to dirt and debris buildup, reducing the need for frequent cleaning and maintenance.

5. Wide Range of Applications

The C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is suitable for use in a wide range of applications, including marine, food processing, and chemical processing industries. The chain is also commonly used in mining, construction, and agricultural applications, as well as in high-temperature and high-moisture environments.

Conclusion

The C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality roller chain that provides superior strength and corrosion resistance. With its extended service life, easy maintenance, and wide range of applications, this roller chain is an excellent choice for demanding applications that require reliable performance in harsh environments.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the sales agent of Ever-power Group in the Netherlands. We are proud to present our C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, which showcases our unique selling points and emphasizes our product quality and exceptional services. Our roller chains are known for their durability, reliability, and superior performance.

With a focus on precision engineering, our stainless steel roller chains are designed to withstand demanding applications in various industries. Our chains are manufactured using high-grade materials, ensuring exceptional strength and resistance to corrosion. We prioritize quality at every stage of production, from design to final inspection, to deliver products that exceed customer expectations.

In addition to the C100SS-2 Duplex Stainless Steel Roller Chain, we offer a wide range of other stainless steel roller chains to meet diverse industrial needs. Whether you require standard roller chains or specialized chains for specific applications, we have you covered. Our extensive selection ensures that you can find the perfect chain for your requirements.

Choose RP Techniek BV as your trusted supplier of stainless steel roller chains. We combine our expertise, exceptional products, and outstanding service to provide you with the most reliable and efficient solutions for your industrial needs.

Sprockets for Sale

When it comes to finding the perfect match for the C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates, our company offers a wide range of different types of sprockets for sale. Whether you need a standard sprocket, a custom-designed sprocket, or a specialized sprocket for a specific application, we have you covered.

Our sprockets are made from high-quality materials and undergo rigorous testing to ensure durability and performance. We understand the importance of reliability and precision in chain and sprocket systems, which is why we only offer top-notch products.

With our diverse selection, you can choose from various sizes, tooth counts, and configurations to find the perfect fit for your needs. Whether you require a small sprocket for light-duty applications or a large sprocket for heavy-duty industrial machinery, we have options to meet your requirements.

Take a look at the image below to get a glimpse of the sprockets we have available:

Contact us today to discuss your specific requirements and find the ideal sprocket to complement your C100SS-2 Duplex Stainless Steel Roller Chain with Straight Side Plates.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...