In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications for C100SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates

- Chain Type: Simplex roller chain

- Material: Stainless steel

- Plate Type: Straight side plates

- Pitch Size: 1 inch

- Roller Diameter: 0.625 inch

- Overall Width: 0.75 inch

- Pin Diameter: 0.3125 inch

- Average Tensile Strength: 7,920 pounds

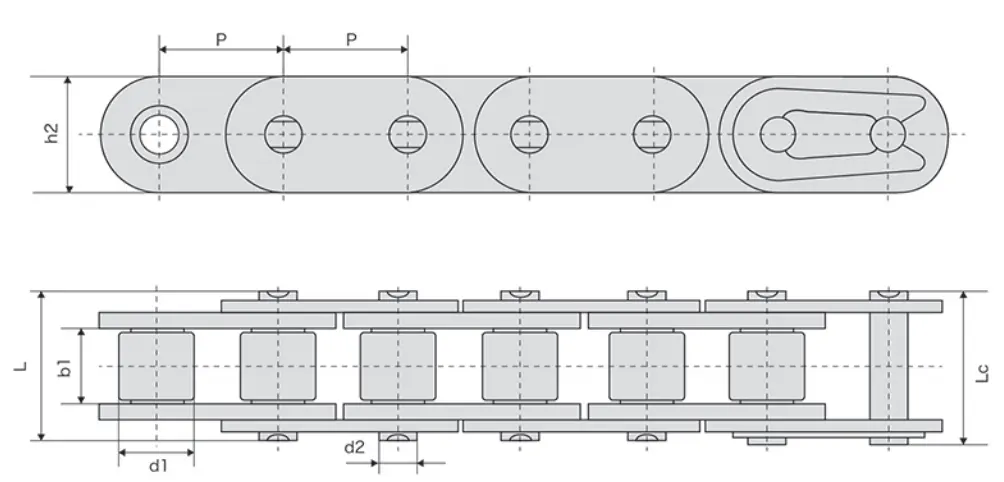

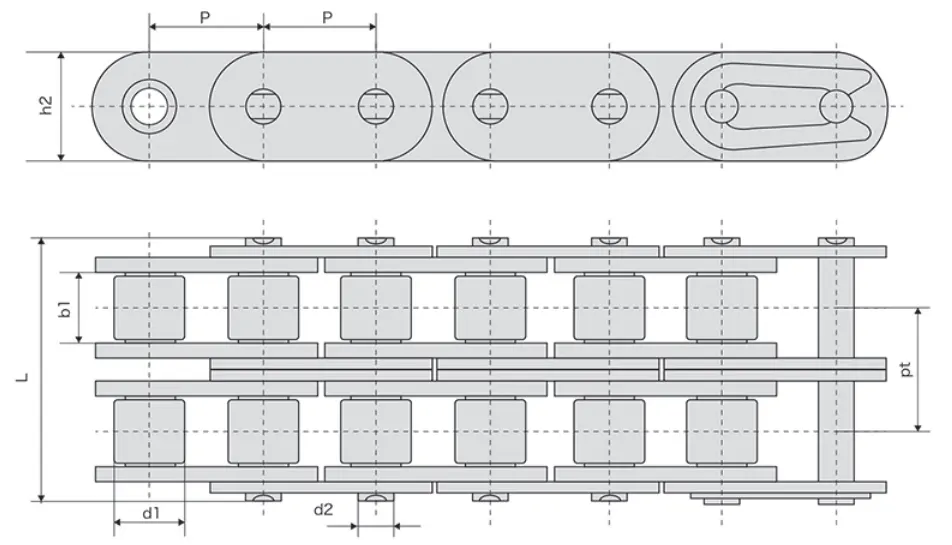

| DIN ISO Chain No. | DIN ISO Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| C08ASS-1 | C40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 18.8 | 12 | 1.5 | 8.46 | 10.5 | 0.73 | |

| C10ASS-1 | C50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 23.3 | 15.09 | 2.03 | 13.32 | 17.64 | 1.23 | |

| C12ASS-1 | C60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 28.3 | 18.0/18.2 | 2.42 | 19.05 | 24.9 | 1.81/1.83 | |

| C16ASS-1 | C80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 36.5 | 24 | 3.25 | 34.02 | 41.64 | 3.09 | |

| C20ASS-1 | C100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 66.52 | 4.56 | |

| C24ASS-1 | C120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 6.86 | |

| C28ASS-1 | C140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 8.49 | |

| C32ASS-1 | C160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 163.34 | 11.5 | |

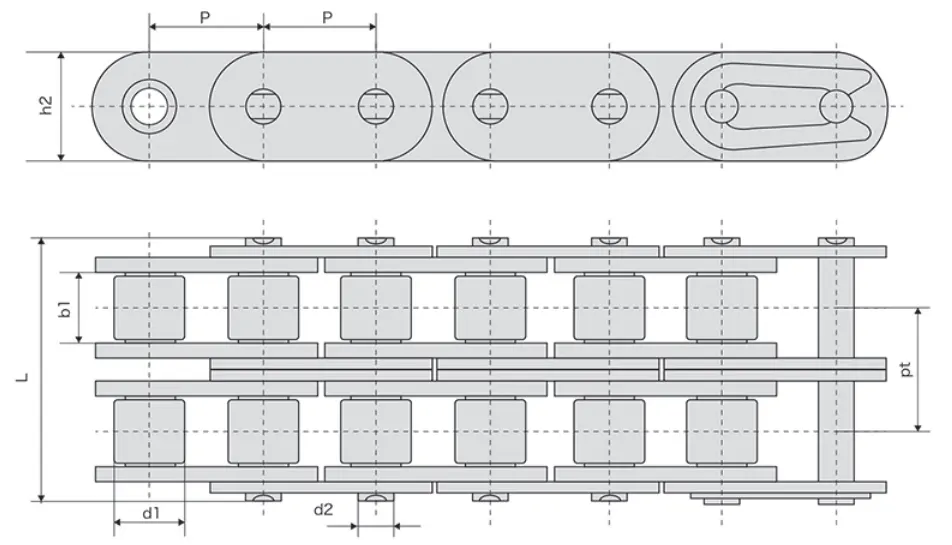

| C08ASS-2 | C40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 33.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.43 |

| C10ASS-2 | C50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 41.4 | 15.09 | 2.03 | 18.11 | 26.64 | 34.86 | 2.42 |

| C12ASS-2 | C60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 51.1 | 18.0/18.2 | 2.42 | 22.78 | 38.16 | 49.26 | 3.58/3.62 |

| C16ASS-2 | C80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 65.8 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 6.12 |

| C20ASS-2 | C100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 9.08 |

| C24ASS-2 | C120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 13.6 |

| C28ASS-2 | C140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 16.86 |

| C32ASS-2 | C160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 315.84 | 22.9 |

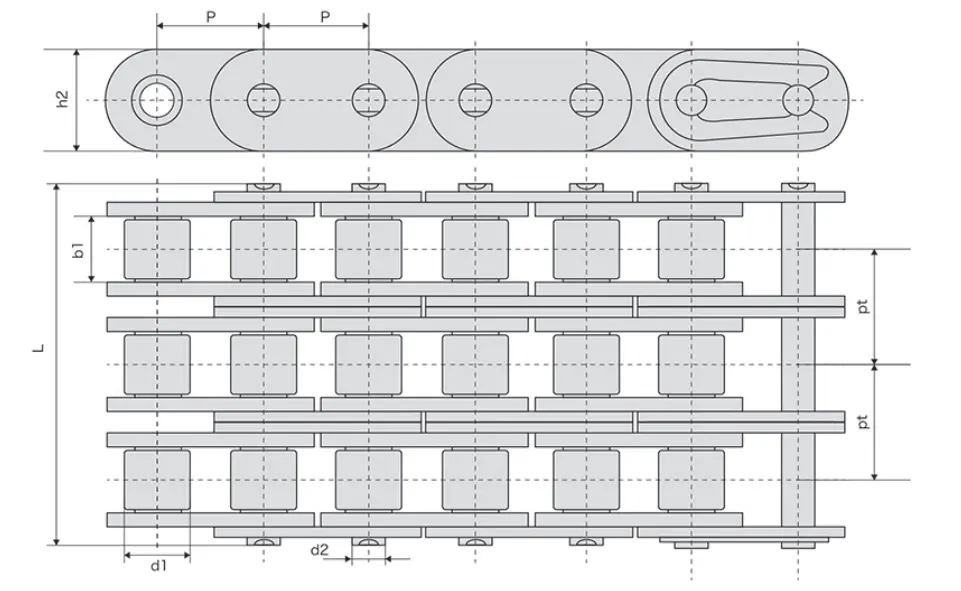

| C08ASS-3 | C40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 47.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 2.14 |

| C10ASS-3 | C50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 59.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.88 | 3.62 |

| C12ASS-3 | C60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.9 | 18.0/18.2 | 2.42 | 22.78 | 57.24 | 66.66 | 5.36/5.41 |

| C16ASS-3 | C80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 95.1 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 9.1 |

| C20ASS-3 | C100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 13.6 |

| C24ASS-3 | C120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 20.43 |

| C28ASS-3 | C140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 310.32 | 355.98 | 25.23 |

| C32ASS-3 | C160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 34.19 |

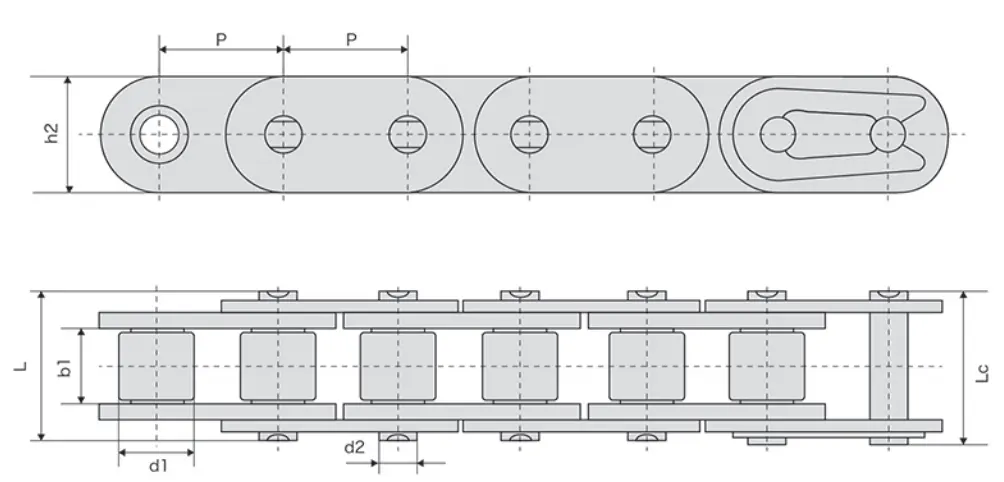

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-1 | 12.7 | 8.51 | 7.75 | 4.45 | 16.8 | 11.8 | 12 | 12.2 | 0.82 |

| C10BSS-1 | 15.875 | 10.16 | 9.65 | 5.08 | 19.2 | 14.6 | 14.9 | 16.2 | 1.07 |

| C12BSS-1 | 19.05 | 12.07 | 11.68 | 5.72 | 22 | 16 | 17.4 | 17.7 | 1.33 |

| C16BSS-1 | 25.4 | 15.88 | 17.02 | 8.28 | 35.6 | 21 | 40.6 | 46.7 | 3.1 |

| C20BSS-1 | 31.75 | 19.05 | 19.56 | 10.19 | 40.4 | 26 | 56 | 64.3 | 4.18 |

| C24BSS-1 | 38.1 | 25.4 | 25.4 | 14.63 | 53.4 | 33.4 | 96 | 115.6 | 7.48 |

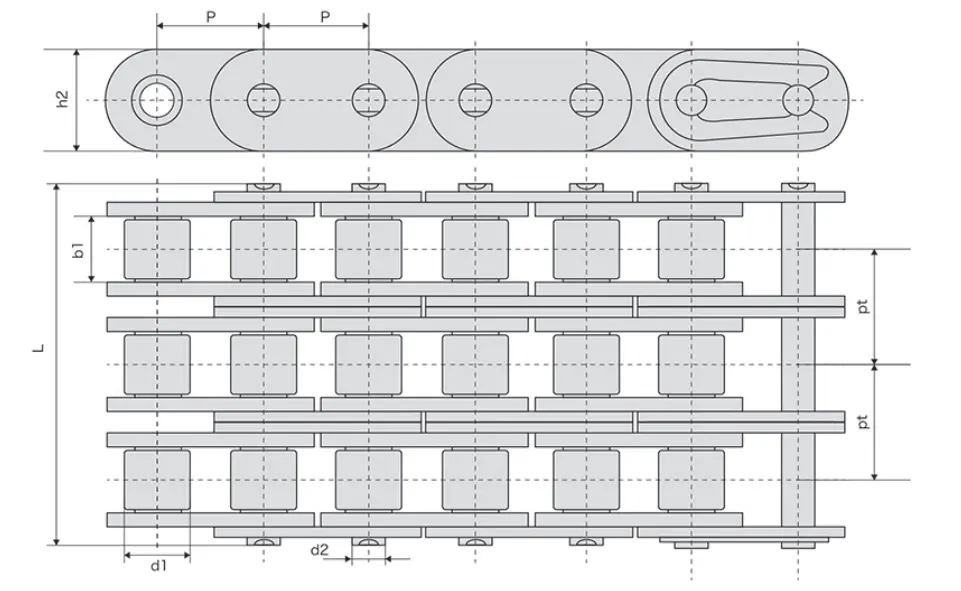

| Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter |

| P | d1 max |

bl min |

d2 max |

L max |

h2 max |

Pt | Q min |

Qo | q | |

| mm | mm | mm | mm | mm | mm | mm | KN | KN | kg/m | |

| CO8BSS-2 | 12.7 | 8.51 | 7.75 | 4.45 | 31 | 11.8 | 13.92 | 22.5 | 23.5 | 1.46 |

| C10BSS-2 | 15.875 | 10.16 | 9.65 | 5.08 | 35.8 | 14.6 | 16.59 | 29.8 | 31.5 | 2.05 |

| C12BSS-2 | 19.05 | 12.07 | 11.68 | 5.72 | 41.5 | 16 | 19.46 | 34.6 | 35.2 | 2.67 |

| C16BSS-2 | 25.4 | 15.88 | 17.02 | 8.28 | 67.2 | 21 | 31.88 | 78 | 89.7 | 6.14 |

| C20BSS-2 | 31.75 | 19.05 | 19.56 | 10.19 | 77.7 | 26 | 36.45 | 110 | 125.3 | 8.25 |

| C24BSS-2 | 38.1 | 25.4 | 25.4 | 14.63 | 101.8 | 33.4 | 48.36 | 168 | 191.5 | 14.78 |

| C08BSS-3 | 12.7 | 8.51 | 7.75 | 4.45 | 45 | 11.8 | 13.92 | 31 | 32.8 | 2.14 |

| C10BSS-3 | 15.875 | 10.16 | 9.65 | 5.08 | 52.7 | 14.6 | 16.59 | 37.8 | 43.6 | 2.89 |

| C12BSS-3 | 19.05 | 12.07 | 11.68 | 5.72 | 61.5 | 16 | 19.46 | 52 | 61 | 3.9 |

| C16BSS-3 | 25.4 | 15.88 | 17.02 | 8.28 | 99.7 | 21 | 31.88 | 108 | 124.2 | 9.12 |

| C20BSS-3 | 31.75 | 19.05 | 19.56 | 10.19 | 114.3 | 26 | 36.45 | 151.2 | 173.6 | 11.32 |

| C24BSS-3 | 38.1 | 25.4 | 25.4 | 14.63 | 150.4 | 33.4 | 48.36 | 255 | 285.4 | 22.12 |

Introduction

The C100SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality, durable chain that is designed for use in a variety of industrial applications. Made from high-grade stainless steel, this chain is able to resist corrosion, rust, and other forms of damage, making it ideal for use in harsh environments.

Features

High-Grade Stainless Steel

The C100SS-1 chain is made from high-grade stainless steel which is both strong and resistant to corrosion. This makes it ideal for use in harsh environments such as those found in the food and beverage industry, pharmaceutical industry, and chemical industry.

Strengthened Side Plates

The side plates of the C100SS-1 chain are strengthened to provide extra durability and strength. This makes the chain less likely to break or wear down over time, even when subjected to heavy use or high loads.

Wide Temperature Range

The C100SS-1 chain is designed to operate at a wide temperature range, making it ideal for use in both high and low-temperature environments. This makes it suitable for use in applications such as food processing, where the temperature can vary greatly.

Quiet Operation

The C100SS-1 chain is designed to operate quietly, making it ideal for use in applications where noise levels need to be kept low. This makes it suitable for use in environments such as hospitals or laboratories where noise levels need to be kept to a minimum.

Easily Maintained

The C100SS-1 chain is designed to be easily maintained, with simple cleaning and lubrication procedures. This helps to extend the life of the chain, reducing downtime and maintenance costs.

Applications

The C100SS-1 chain is suitable for use in a wide range of industrial applications, including:

- Food and beverage processing and packaging

- Pharmaceutical manufacturing

- Chemical processing and manufacturing

- Pulp and paper manufacturing

- Automotive manufacturing

Conclusion

The C100SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates is a high-quality, durable chain that is ideal for use in a wide range of industrial applications. Its high-grade stainless steel construction, strengthened side plates, wide temperature range, quiet operation, and easy maintenance make it the perfect choice for anyone looking for a reliable and long-lasting chain.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We pride ourselves on providing high-quality, durable, and reliable C100SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates. Our products are uniquely designed to meet the demands of our customers, providing excellent performance and long-lasting service.

Our stainless steel roller chains are manufactured using only the highest quality materials, ensuring that they are resistant to corrosion, wear and tear, and other environmental factors. Our commitment to quality extends to our customer service, where we are dedicated to providing prompt, efficient, and reliable support to our customers.

In addition to the C100SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates, we also offer a wide range of other stainless steel roller chains that are suitable for various applications. Whether you need a heavy-duty chain for industrial use or a lightweight chain for a conveyor system, we have you covered.

At RP Techniek BV, we are committed to providing our customers with the best quality products and services. We take pride in our production capabilities and are confident that we can meet all your needs when it comes to stainless steel roller chains.

Sprockets for Sale

If you are in need of compatible sprockets for C100SS-1 Simplex Stainless Steel Roller Chain with Straight Side Plates, you have come to the right place. Our company offers a wide range of sprockets to complement your roller chain needs.

Our sprocket selection includes various sizes, materials, and tooth counts to accommodate different chain requirements. Whether you need a standard steel sprocket for industrial applications or a custom-machined sprocket for a specialized project, we have what you need.

Our sprockets are manufactured with high-quality materials and precision engineering to ensure durability and reliability. We also offer a range of surface treatments and coatings to enhance the performance and longevity of our sprockets.

Our commitment to customer satisfaction means that we offer competitive pricing and excellent customer service. Our knowledgeable staff is available to answer any questions or help you find the right sprocket for your application.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...