In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

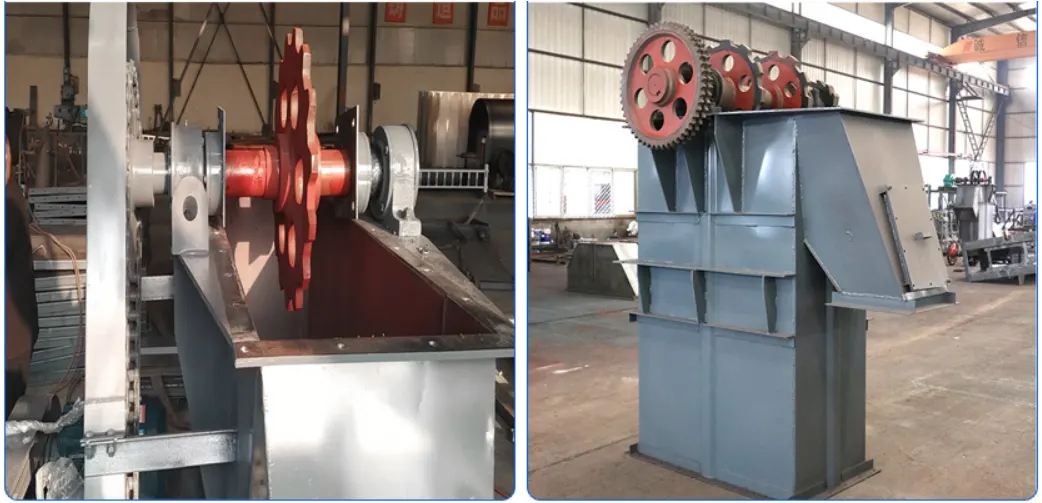

Bucket Elevator Sprocket

The sprocket for bucket elevator is used to mesh with a block of accurate pitch on a knuckle chain ring or cable, and is a solid or spoked gear that meshes with a roller chain to transmit motion. The sprocket tooth shape must ensure that the chain can save energy to enter and exit the mesh smoothly and freely, minimize the impact and contact stress of the chain links when meshing, and be easy to process. Our bucket elevator sprocket material ensures that the teeth have sufficient strength and wear resistance, so the sprocket tooth surface is generally heat-treated to a certain hardness.

Bucket Elevator Sprocket Types and Characteristics

| According to the structural form | According to the installation position | According to the transmission mode |

| Smooth sprocket: With a smooth surface, it is suitable for scenarios where chain wear is relatively small and operation is stable, but it is prone to chain detachment.

Toothed sprocket: The toothed design can effectively prevent the chain from swinging left and right, avoiding chain disengagement. It is suitable for heavy loads or conditions where the chain is prone to elongation. |

Head sprocket: It drives the chain to run and needs to withstand a large torque. It is usually made of high-strength materials and has an optimized tooth profile design.

Lower sprocket: It is used for redirecting and tensioning the chain and needs to be equipped with a tensioning device to accommodate the elongation of the chain after wear. |

Plate chain sprocket: In conjunction with the plate chain, it is suitable for working conditions with large conveying volume and high wear, such as the mining and building materials industries.

Chain sprocket: In conjunction with the chain, it is suitable for scenarios with light loads and medium to small conveying volumes, such as grain and feed processing. |

Plate Chain Bucket Elevator Sprocket VS Ring Chain Bucket Elevator Sprocket

There are mainly two types of bucket elevator sprockets: plate chain bucket elevator sprockets and ring chain bucket elevator sprockets.

Plate chain bucket elevator sprocketToothed design: The sprocket of the bucket elevator with plate chain has a toothed design, which enables better meshing with the traction chain. Complex discharge port: The design of its discharge port is rather complex, with a certain arc-shaped curvature, suitable for gravity discharge method. |

Ring chain bucket elevator sprocketSmooth surface : The sprocket of the chain bucket elevator has a smooth surface without teeth or grooves. Simple discharge port : The design of its discharge port is relatively simple and suitable for inertial discharge mode. |

|

|

The Design and Application of Bucket Elevator Sprocket

Our sprocket design for bucket elevator system has been precisely calculated and optimized to ensure excellent performance in various industrial scenarios, covering fields such as agriculture, mining, and building material processing. Designed specifically for efficient material transportation, bucket elevator sprocket pays attention to every detail in its design. From tooth profile optimization to material selection, all meet high-standard industrial requirements to ensure durability and performance stability. We also offer custom bucket elevator sprocket, which can be customized in terms of size and performance according to the specific requirements of customers to ensure a perfect match with the bucket elevator chain and other bucket elevator parts. Furthermore, our high torque bucket elevator sprocket is specially designed for heavy loads, suitable for high-intensity working environments, ensuring long-term stable operation and reducing maintenance costs. Choose our bucket conveyor sprocket for reliable power for your delivery system.

Bucket Elevator Sprocket Maintenance Guide

- Regular inspection

Check the wear condition of the sprocket tooth surface and the meshing state of the chain and sprocket, and adjust the tensioning device in time to prevent the chain from being too loose or too tight. - Lubrication management

Select the appropriate lubrication method (such as oil drip lubrication or oil spray lubrication) based on the working conditions to reduce tooth surface wear and noise. - Replace in time

When the tooth thickness of the sprocket is worn by more than 10% of the original tooth thickness or cracks appear, it should be replaced immediately to avoid equipment failure.

Bucket Elevator Parts

The bucket elevator mainly consists of the following parts:

- Hopper: used for loading and unloading materials.

- Traction chain: connects the hopper and transmits power.

- Drive unit: Provides the power source, usually an electric motor.

- Housing: Protects the internal structure and provides the necessary support.

- Tensioning device: Maintains the tension of the chain to ensure stable operation.

Bucket Elevator Sprocket Supplier

RP Techniek BV, as the sales agent of Ever-power Group in the Netherlands, has been deeply engaged in the field of bucket elevator sprockets and possesses industry-leading professional capabilities. We are equipped with advanced CNC machining centers and precision testing equipment. Combined with years of technological accumulation, we can precisely match the requirements of different working conditions and produce high-strength and wear-resistant sprocket products. The quality has passed the ISO certification standard.

Our core strength lies in the full-process service: from the customized design provided by the technical team (such as tooth profile optimization and material adaptation), to the rapid response after-sales guarantee, and then to the efficient logistics to ensure global delivery, we always take customer needs as the guide. Meanwhile, relying on the R&D resources of Ever-power Group, we continuously innovate to help customers improve the efficiency and service life of their equipment. Contact now!

Additional information

| Edited | Zqq. |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...