In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Parameters of Boiler Sprocket

| Parameter | Common Values/Options |

| Type | Single/Double/Triple Strand |

| Material | ZG40Cr, 35CrMo, 45# Steel, Alloy Steel |

| Pitch (P) | 50mm, 63.5mm, 80mm, 100mm, etc. |

| Number of Teeth (Z) | 10-30 teeth (Designed according to boiler power and chain specifications) |

| Bore Diameter (D) | 30mm, 40mm, 50mm, 60mm, etc. |

| Hub Diameter | Designed for load and shaft diameter |

| Face Width | 20mm, 30mm, 40mm, etc. |

| Heat Treatment | Quenching & Tempering, Carburizing |

| Standard | GB/T 1243, ISO 606, ANSI B29.1 |

| Max RPM | 10-50 RPM (Typical Low Speed Heavy Load) |

| Lubrication | Grease Lubrication, Oil Bath |

Selection basis: Boiler sprocket parameters should be determined according to chain specifications (e.g. pitch, width), boiler load and transmission power.

Customized requirements: Non-standard boiler sprockets may need to provide detailed drawings, including keyway dimensions, tolerances, etc.

The Basic Functions of the Boiler Sprocket

The boiler sprocket is the core component of the chain grate drive system, and its core functions include:

Power transmission and fuel transportation: The sprocket is driven by a motor or reducer, which slowly moves the chain and grate, allowing the coal to be evenly advanced from the feed end to the slag discharge end. During this process, the fuel successively undergoes the stages of drying, combustion and burnout to ensure the maximization of combustion efficiency, while the ash and slag are stably discharged from the furnace.

Motion synchronous control: The precise meshing of the sprocket and the chain ensures the synchronous operation of all parts of the grate, avoiding fuel accumulation or incomplete local combustion caused by speed deviation. This stability is crucial for maintaining the balanced heat load of the boiler and reducing mechanical wear, directly affecting the long-term operational reliability of the boiler.

In addition, the high-temperature resistant and wear-resistant design of the sprocket enables it to operate continuously under harsh working conditions, which is a key guarantee for the efficient operation of coal-fired boilers.

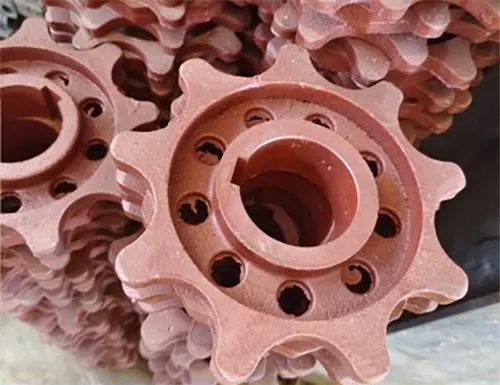

Boiler Chain Sprocket Structure and Characteristics

Boiler Sprocket Material: Usually, high-strength alloy steel (such as ZG40Cr, 35CrMo, etc.) is adopted, which is heat-resistant, wear-resistant and impact-resistant.

Tooth profile design: The tooth profile needs to be precisely matched with the chain. Common types include single-row or multi-row tooth structures. The tooth surface may undergo quenching treatment to extend its service life.

Installation method: Connect to the drive shaft through a keyway or flange. Strict alignment is required to avoid uneven wear.

How to Replace a Boiler Sprocket?

The boiler sprocket is a key component in the boiler transmission system. After long-term use, it may wear out or be damaged, affecting the operational efficiency of the equipment. The following are the basic steps for replacing the boiler sprocket.

- Turn off the power supply of the boiler

Make sure the boiler is completely powered off and wait for the equipment to cool down to avoid scalding or electric shock. - Open the protective cover

Carefully remove the protective cover at the sprocket part to expose the sprocket and the transmission system. - Loosen the chain or belt

If the sprocket is connected to a chain or belt, first loosen the tensioning device and remove the chain or belt. - Remove the old sprocket

Use an appropriate tool to remove the bolts or nuts that fix the sprocket, and gently take the sprocket off the shaft. - Inspection and cleaning

Check whether there is any wear or impurities in the bearings, shafts and other parts, and clean them. Apply lubricating oil when necessary. - Install the new sprocket

Align the new sprocket and install it on the shaft. Tighten the fixing bolts to ensure a firm installation without any offset. - Reinstall the chain or belt

Reinstall the chain or belt back to its original position and adjust the tension to an appropriate level to ensure normal operation. - Restore and test the equipment

Install the protective cover properly, power on and start the boiler, and observe whether the sprocket operates smoothly and if there is any abnormal noise.

Sprocket Maintenance for Boilers

As an important component of the boiler transmission system, the sprocket's operating condition directly affects the working efficiency and service life of the boiler. To ensure the stable operation of the boiler system, it is crucial to regularly maintain and service the sprocket. Here are the boiler sprocket maintenance tips.

- Regular cleaning

After long-term operation, the surface of the sprocket is prone to accumulate dust, oil stains or impurities. It is necessary to clean it regularly with a clean cloth or brush to avoid impurities accelerating the wear of the sprocket. - Check the wear condition

Regularly check whether the teeth of the sprocket are worn, cracked or deformed. If any abnormality is found, replace it in time to prevent transmission failure and equipment failure. - Lubrication and maintenance

Lubricate the sprocket and chain with special lubricating oil to reduce friction and extend service life. The lubrication frequency should be adjusted according to the usage frequency and environmental conditions. - Check the tension

Improper tightness of the chain can affect the operation of the sprocket. It is necessary to regularly check the tension of the chain to ensure that it is neither too tight nor too loose and operates smoothly. - Fastening inspection

Check whether the bolts fixing the sprocket are loose and ensure that the sprocket is firmly installed on the shaft to prevent it from falling off or slipping during operation.

Through regular maintenance and inspection, not only can the failure rate of the sprocket be reduced, but also the overall performance of the boiler can be improved and the service life of the equipment can be prolonged. Maintenance may be minor, but security guarantee is significant.

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...