In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications of 80-2-TRSS Double Strand Stainless Steel Conveyor Chains with Top Rollers

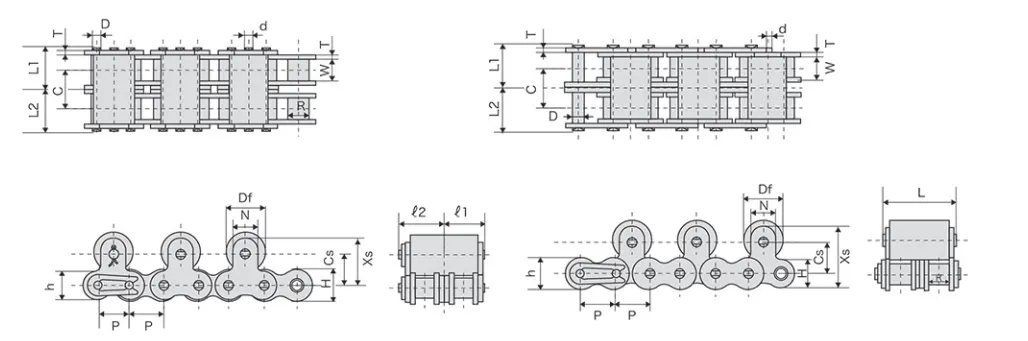

The specifications for the 80-2-TRSS Double Strand Stainless Steel Conveyor Chains equipped with Top Rollers are as follows:

- Chain Size: 80-2

- Chain Material: Stainless Steel

- Number of Strands: Double Strand

- Roller Type: Top Rollers

| Chain No | P | W | R | C | D | L1 | L2 | h | H | T | Df | Cs | Xs | N | L | ¦Ã1 | ¦Ã2 | d |

| 40-2-TRSS | 12.7 | 7.95 | 7.94 | 14.4 | 3.97 | 15.45 | 17.15 | 10.4 | 12 | 1.5 | 15.88 | 12.7 | 17.45 | 9.5 | 28.3 | 15.45 | 16.95 | 3.97 |

| 50-2-TRSS | 15.875 | 9.53 | 10.16 | 18.1 | 5.09 | 19.35 | 21.15 | 13 | 15 | 2 | 19.05 | 15.9 | 22.25 | 12.7 | 34.3 | 19.35 | 21.15 | 5.09 |

| 60-2-TRSS | 19.05 | 12.7 | 11.91 | 22.8 | 5.96 | 24.25 | 26.25 | 15.6 | 18.1 | 2.4 | 22.23 | 18.3 | 26.25 | 15.9 | 43.4 | 24.25 | 26.75 | 5.96 |

| 80-2-TRSS | 25.4 | 15.88 | 15.88 | 29.3 | 7.94 | 30.9 | 33.9 | 20.8 | 24.1 | 3.2 | 28.58 | 24.61 | 34.15 | 19.1 | 55 | 30.9 | 33.9 | 7.94 |

| 100-2-TRSS | 31.75 | 19.05 | 19.05 | 35.8 | 9.54 | 37.7 | 40.8 | 26 | 30.1 | 4 | 39.69 | 31.8 | 44.5 | 25.4 | 66.9 | 37.7 | 40.8 | 9.73 |

Overview

The 80-2-TRSS double strand stainless steel conveyor chains with top rollers consist of two parallel strands made of stainless steel, linked via top rollers. These chains are widely used in material handling systems that demand durability and resistance to corrosion.

Features and Benefits

Stainless Steel Construction

A key characteristic of these chains is their construction from stainless steel. This material is known for its exceptional durability and resistance to corrosion, allowing it to endure harsh conditions and high temperatures. Therefore, it is particularly well-suited for applications that involve significant exposure to moisture and wear.

High Strength

These chains also offer remarkable strength. The stainless steel material provides the capability to handle heavy loads and considerable tension without succumbing to failure or deformation. This makes them ideal for demanding material handling scenarios.

Double Strand Design

The double strand configuration enhances the strength and stability of these chains compared to single strand alternatives. The two parallel strands work in unison to evenly distribute loads, thereby minimizing stress on individual links and bolstering the chain's overall strength.

Top Rollers

The inclusion of top rollers on these chains serves to minimize friction and wear at the interface between the chain and the conveyor. These rollers facilitate smooth and quiet movement of the chain, leading to reduced noise and vibration throughout the material handling system.

Applications

Food Processing

The remarkable strength and corrosion resistance of these chains make them particularly suitable for food processing applications. They can endure exposure to aggressive chemicals and high temperatures without degrading, thus ensuring their safe and reliable use in food-related tasks.

Beverage Production

These chains are also well-fitted for beverage production applications due to their smooth and quiet operational characteristics. They transport products along the conveyor seamlessly, minimizing the risk of spills and damage.

Automotive Manufacturing

Given their high strength and durability, these chains are a fitting choice for automotive manufacturing environments. They can endure the heavy loads and intense tension commonly observed in automotive assembly processes, ensuring reliable movement of components and parts along production lines.

Conclusion

The 80-2-TRSS double strand stainless steel conveyor chains with top rollers are exceptionally strong, corrosion-resistant, and versatile, making them suitable for a diverse array of material handling applications. Whether in food processing, beverage production, automotive manufacturing, or any sector that demands dependable, high-performance conveyor chains, these products are an outstanding option.

Choose Our Stainless Steel Roller Chains

RP Techniek BV proudly serves as the official sales representative of Ever-power Group in the Netherlands. Our 80-2-TRSS Double Strand Stainless Steel Conveyor Chains with Top Rollers stand as a testament to the quality and service excellence of our offerings. We are dedicated to our manufacturing capabilities and are committed to providing exceptional solutions to our customers.

In addition to the 80-2-TRSS model, we provide a wide selection of stainless steel roller chains. All our chains are crafted to meet the highest quality standards, ensuring longevity and outstanding performance. Our team of professionals is committed to delivering exceptional customer service and support, helping you identify the best solutions for your specific needs.

Sprockets for Sale

Finding the appropriate sprocket is crucial for optimal machinery performance when using the 80-2-TRSS double strand stainless steel conveyor chains with top rollers. Our company offers a range of compatible sprockets, making it easy for you to find the right match for your requirements.

Our sprocket selection features various materials, sizes, tooth counts, and designs. Recognizing that each application presents unique challenges, we provide a diverse array of sprocket options. Whether you seek a standard or a custom-designed sprocket, we can fulfill your needs.

Manufactured from high-quality materials using precise techniques, our sprockets ensure durability and reliability, capable of handling heavy loads and enduring challenging conditions. Furthermore, we offer competitive pricing and prompt delivery to ensure you receive your sprockets as needed.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...