In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

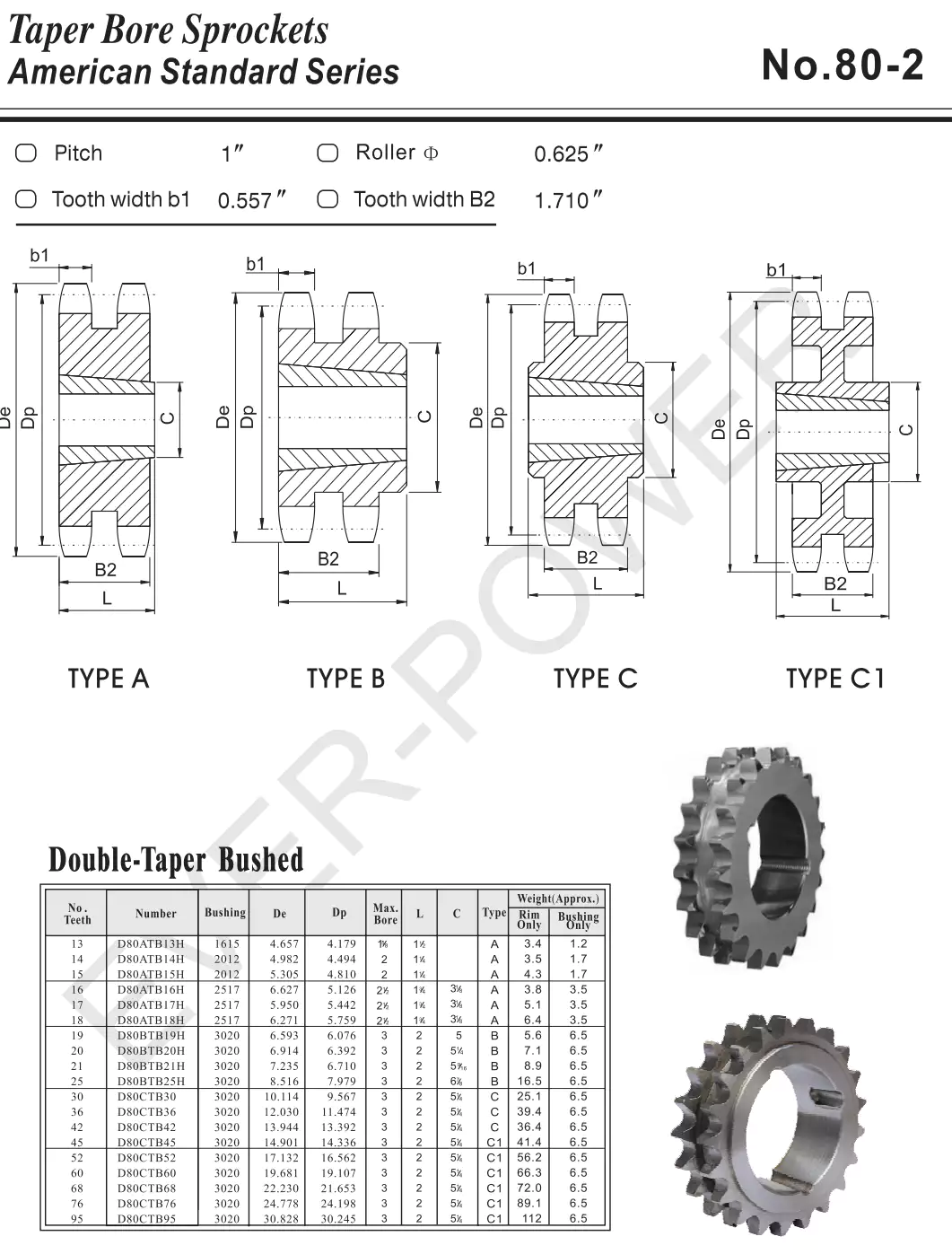

#80-2 1″ Taper Bore Sprocket

The #80-2 1″ Taper Bore Sprocket is designed for high-performance applications, offering durability and precision. Engineered with a taper bore design, it ensures easy installation and optimal alignment on shafts. This sprocket is ideal for various machinery, providing reliable power transmission and enhanced efficiency in demanding environments.

#80-2 1" Taper Bore Sprocket Specifications

The #80-2 1" Taper Bore Sprocket, adhering to the American Standard, serves a crucial role in power transmission systems. This sprocket is specifically engineered with a tapered bore design, which enables straightforward installation and effortless removal from a shaft. Its dependable nature and precise positioning make it a favored choice across multiple industries, ensuring broad applicability and effective performance.

Definition and Basic Structure

A taper bore sprocket is distinguished by its tapered bore that facilitates mounting on a shaft through a tapered bushing. This design guarantees a tight and precise fit. The essential components of the sprocket include engaging teeth that work with a chain, a central hub, and the tapered bore for secure mounting on the shaft, ensuring optimal functionality in various applications.

Characteristics and Functions

Taper bore sprockets are recognized for several key characteristics and functions:

- Easy Installation: The tapered bore and bushing design make it simple to install the sprocket onto the shaft, ensuring a secure and tight fit.

- High Precision Positioning: The taper lock mechanism allows for accurate positioning on the shaft, which reduces the risk of misalignment and enhances the efficiency of power transmission.

- Wide Applicability: These sprockets find applications in various power transmission systems, including conveyor systems, industrial machinery, and agricultural equipment.

- Reliability: The taper lock design ensures a secure connection between the sprocket and the shaft, minimizing the risks of slippage or disengagement during operation.

- Low Maintenance Cost: With their durable and reliable construction, taper bore sprockets typically require minimal maintenance, leading to significant cost savings over time.

Installation and Removal Process

Installing and removing a taper bore sprocket involves the following methodical steps:

- Prepare Tools and Materials: Collect the necessary tools, such as a hex key or wrench. Ensure that both the taper lock bushing and sprocket are clean and free from any debris to ensure a smooth installation process.

- Clean Shaft and Sprocket Surface: Make sure that the surfaces of the shaft and sprocket are thoroughly cleaned to facilitate a smooth connection with the taper lock bushing, ensuring optimal performance.

- Place Taper Lock Bushing: Carefully slide the taper lock bushing onto the shaft, ensuring it is properly seated against the shoulder or face of the shaft for effective mounting.

- Install Sprocket: Position the sprocket over the taper lock bushing, making sure the hub aligns accurately with the tapered bore of the bushing for a secure fit.

- Tighten Locking Nut: Utilize the appropriate hex key or wrench to securely fasten the locking nut on the taper lock bushing, ensuring everything is tight and secure.

Manufacturing Process

The manufacturing of taper bore sprockets consists of several critical stages:

- Prepare Raw Materials: Assemble the essential raw materials required for production, typically including steel or various alloys.

- Cutting: Cut the raw materials into the necessary shapes and sizes required for the sprocket.

- Forging or Casting: Depending on the desired outcome, the sprocket may be forged or cast to achieve its strength and specific shape.

- Machining: The sprocket undergoes machining to achieve precise dimensions and tooth profiles that are vital for functionality.

- Teeth Rolling: The teeth are rolled to ensure that they engage accurately and smoothly with the chain during operation.

- Heat Treatment: Apply heat treatment processes to the sprocket to enhance its hardness and overall durability, ensuring long-lasting performance.

- Surface Treatment: The surface of the sprocket is treated to improve its resistance to corrosion and enhance its aesthetic appearance.

- Quality Inspection: Conduct thorough quality inspections to ensure that the sprockets meet the necessary standards and specifications required for safe and effective use.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, specializing in high-quality industrial components. Our product range includes the #80-2 1" Taper Bore Sprocket, designed with durability and efficiency for various applications. The robust taper lock design ensures a secure fit on shafts, significantly reducing the risk of slippage and enhancing performance. We are committed to providing exceptional service and support to our customers, helping you find the ideal products for your specific needs.

In addition to our standard sprockets, we offer customized solutions tailored to our clients' specifications. We encourage customers to provide drawings or samples for bespoke manufacturing, ensuring that we meet your unique requirements with precision.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...