In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

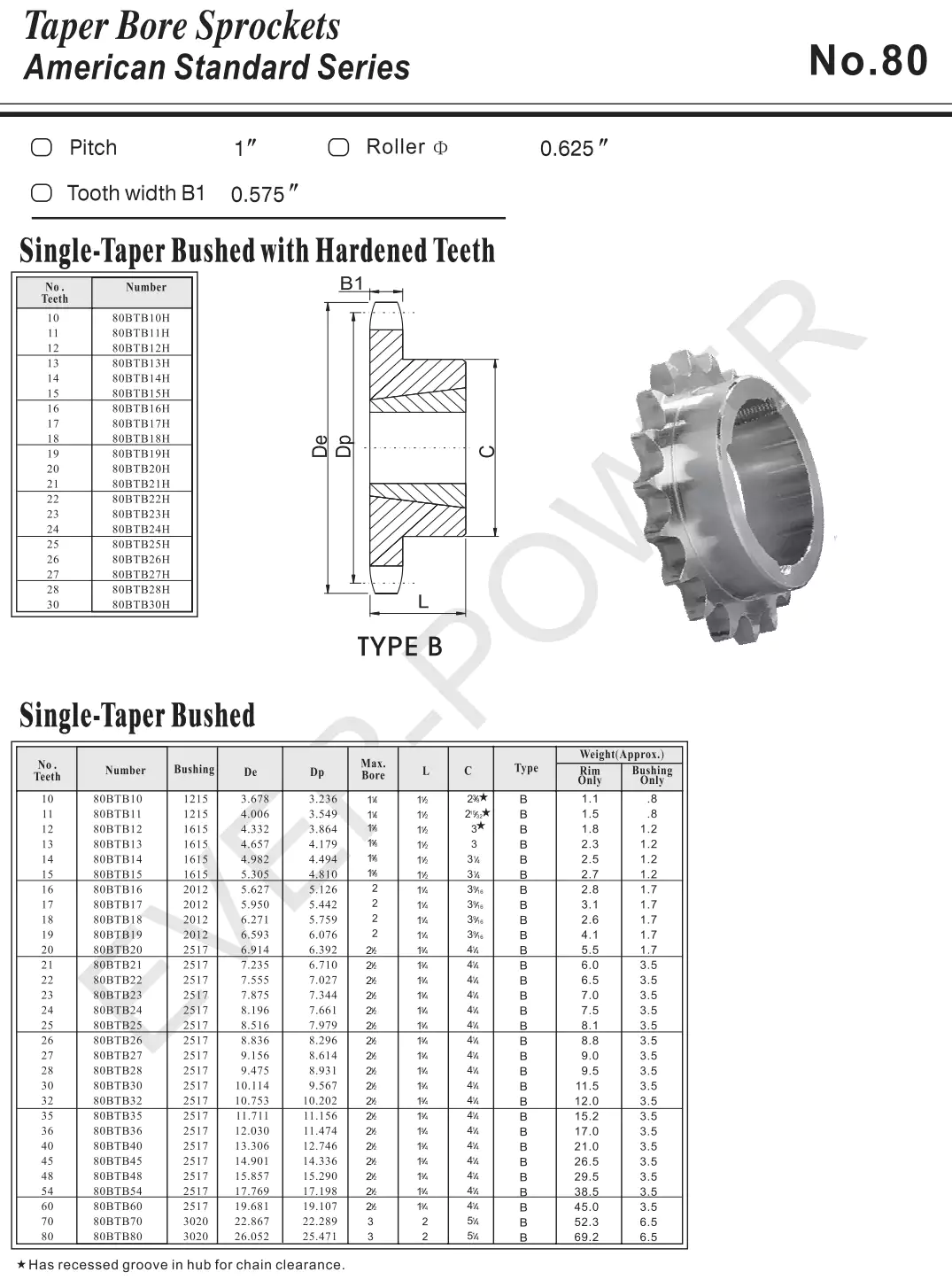

#80 1″ Taper Bore Sprocket

The #80 1″ Taper Bore Sprocket is a high-quality, durable component designed for efficient power transmission in various machinery. With its precise taper design, it ensures a secure fit on shafts, minimizing slippage. Ideal for industrial applications, this sprocket enhances performance and longevity, making it a reliable choice for your needs.

#80 1" Taper Bore Sprocket Specifications

#80 1" Taper Bore Sprocket is frequently used in power transmission systems due to its efficient design. The core principle of a taper bore sprocket is to simplify the installation and removal process, eliminating the need for specialized tools or expertise. This is achieved using a tapered bushing that fits snugly into the bore of the sprocket, which guarantees accuracy and dependability during operation.

Definition and Basic Structure

A taper bore sprocket consists of a tapered bore and a corresponding bushing, which ensures a secure fit on the shaft. The fundamental construction includes a sprocket with a tapered bore, a matching tapered bushing that fits within this bore, and a locking mechanism designed to secure the bushing in place, ensuring stability during operation.

Features and Applications

- Easy to install: The design of the tapered lock bushing greatly simplifies the installation process, allowing for a quick setup without the requirement of additional tools or in-depth training.

- High precision positioning: The tapered bushing provides a precise fit, ensuring that the sprocket is securely attached to the shaft, reducing the risk of misalignment.

- Wide applicability: These sprockets are widely utilized in power transmission systems across various sectors and industries.

- Reliability: Taper bore sprockets are engineered for exceptional reliability and long-lasting performance, which helps to minimize maintenance needs and replacement frequency.

- Low maintenance costs: The design contributes to low upkeep requirements, significantly reducing overall ownership costs for users.

Easy to Install and Remove

The tapered lock bushing allows for a straightforward process to both install and remove the sprocket. To install, simply insert the bushing into the tapered bore and align the sprocket with the shaft. After this alignment, tighten the locking mechanism securely. For removal, you simply need to loosen the locking mechanism and carefully slide the sprocket off the shaft without any hassle.

Installation and Removal Process

- Prepare tools and materials: Before starting the installation, gather all necessary tools and materials to ensure a smooth process.

- Clean shaft and sprocket surfaces: It's essential to ensure that both surfaces are devoid of any dirt, debris, or contaminants that could affect installation.

- Place taper lock bushing: Insert the taper lock bushing into the sprocket's tapered bore to establish a firm connection.

- Install sprocket: Align the sprocket with the shaft and carefully slide it onto the taper lock bushing to complete the setup.

- Tighten locking nut: Utilize a torque wrench to tighten the locking nut according to the torque specifications provided by the manufacturer for optimal security.

Manufacturing Process

The manufacturing process of a sprocket encompasses several critical stages, which include:

- Prepare raw materials: High-quality steel and other materials are selected to ensure durability and performance.

- Cut to size: The raw material is precisely cut to the required dimensions for the sprocket.

- Forging or casting: The material is shaped through either forging or casting methods, depending on the design requirements.

- Machining: The sprocket undergoes machining to achieve specific tolerances and specifications to meet industry standards.

- Rolling teeth: The teeth of the sprocket are rolled to ensure consistent quality and precision in their formation.

- Heat treatment: This step enhances the strength and durability of the sprocket, making it suitable for heavy-duty applications.

- Surface treatment: The surface of the sprocket is treated to protect against rust and corrosion, prolonging its lifespan.

- Quality inspection: A comprehensive inspection is conducted to confirm that the sprocket meets all specifications and quality standards.

Sprockets Supplier in Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, recognized as a leading manufacturer in the sprocket sector. One of our flagship products is the #80 1" Taper Bore Sprocket, engineered for outstanding performance and durability across a variety of industrial applications. Our sprockets are crafted from premium materials, ensuring they are both reliable and long-lasting.

In addition to offering standard sprockets, we provide tailor-made solutions designed to meet the unique requirements of our clients. Whether you're seeking specialized designs or non-standard specifications, we encourage customers to present their drawings or samples for personalized manufacturing. Our dedicated team is committed to delivering exceptional service and high-quality products that cater to the diverse needs of our clientele.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...