In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

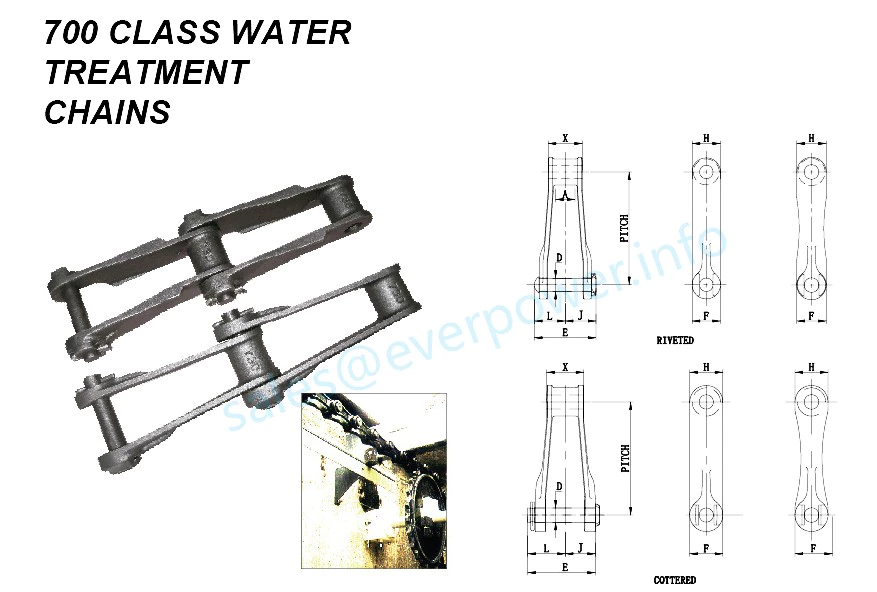

Specifications of 720S Wastewater Treatment Chain

- Material: Stainless Steel

- Chain Pitch: 1 inch

- Chain Width: 6 inches

- Maximum Working Load: 10,000 lbs

- Operating Temperature Range: -40¡ãF to 300¡ãF

- Corrosion Resistance: Excellent

- Chain Speed: Up to 100 ft/min

- Chain Tensile Strength: 50,000 lbs

- Warranty: 2 years

| Chain No. | Pitch in Inches | Weight Per Foot LBS. | Average Ultimate Strength LBS. | Maximum Working Load LBS. | A | C | D | E | F | H | X | Available Attachments |

| 720 | 6 | 4.5 | 27500 | 3720 | 1.12 | 3.44 | 0.69 | 3.31 | 1.5 | 1.38 | 1.81 | A2,A53,AM116,F2,F22-6,F22-8,K1,K2,M1,PDF2,PDF22-6,PDF22-8 |

| 720S | 6 | 5.3 | 37500 | 4200 | 1.12 | 3.81 | 0.75 | 3.69 | 1.56 | 1.44 | 1.88 | A2,A53,AM116,F2,F22-6,F22-8,K2,M1 |

| MS720S | 6 | 6.2 | 41000 | 4200 | 1.12 | 3.81 | 0.75 | 3.69 | 1.56 | 1.44 | 1.88 | A2,A42,F2,F22-6,F22-8,K2,M1 |

| 730 | 6 | 6.35 | 37500 | 4500 | 1.12 | 3.81 | 0.75 | 3.69 | 1.75 | 1.5 | 2 | A2,A42,F2,F22-6,F22-8,K2,M1 |

| MS730 | 6 | 6.3 | 41000 | 4500 | 1.12 | 3.81 | 0.75 | 3.69 | 1.75 | 1.5 | 2 | F2,F22-6,F22-8,M1 |

| 788 | 2.609 | 4.6 | 22000 | 2740 | 0.94 | 3.31 | 0.56 | 3.19 | 1.19 | 0.88 | 1.62 | None |

| TAW710 | 6 | 6.3 | 27500 | 4220 | 5.63 | 3.81 | 0.69 | 2.38 | 1.38 | 1.13 | 3.03 | A2,K2 |

| TAW720 | 6 | 4.3 | 27500 | 3700 | 3.55 | 3.81 | 0.69 | 1.13 | 1.5 | 1.38 | 1.81 | A474,F2,F3,F22-6,F22-8,K2,M1 |

| TAW720S | 6 | 5.3 | 37500 | 4070 | 3.84 | 3.81 | 0.75 | 1.13 | 1.56 | 1.44 | 1.88 | A21,A53,A474,AM116,F2,F3,F22-6,F22-8,M1 |

| TAW730 | 6 | 6.1 | 420000 | 4310 | 3.81 | 3.31 | 0.75 | 1.13 | 1.75 | 1.5 | 2 | A42,A53,AM116,F2,F3(SF4),F22-6,F22-8,M1,K2 |

Introduction

The 720S Wastewater Treatment Chain is a highly efficient and comprehensive solution for treating wastewater. This system combines several advanced technologies to remove contaminants and impurities from water, making it safe for discharge or reuse.

Primary Treatment

The primary treatment stage of the 720S Wastewater Treatment Chain involves the removal of large solids and debris from the water. This is done through a process called screening, where the wastewater is passed through screens of various sizes to capture any large objects. The water then moves on to the next stage of treatment.

Secondary Treatment

In the secondary treatment stage, the 720S Wastewater Treatment Chain uses a biological process to remove organic matter from the water. This is done by introducing microorganisms to the wastewater, which consume the organic matter as their food source. As the microorganisms consume the organic matter, they produce a type of sludge that can then be removed from the water.

Tertiary Treatment

The tertiary treatment stage of the 720S Wastewater Treatment Chain is designed to remove any remaining contaminants and impurities from the water. This is done through a variety of methods, such as filtration, disinfection, and chemical treatment. The result is water that is safe for discharge or reuse.

Effluent Discharge

The effluent discharge stage of the 720S Wastewater Treatment Chain is where the treated water is released back into the environment. This water is carefully monitored to ensure that it meets all relevant regulatory standards for discharge. Once the water has been discharged, the cycle begins again with the treatment of new wastewater.

Benefits

The 720S Wastewater Treatment Chain offers a number of important benefits. It is a cost-effective solution for treating wastewater, as it combines several advanced technologies to achieve maximum efficiency. It is also highly customizable, allowing it to be tailored to the specific needs of different industries and applications. Additionally, the system is environmentally friendly, as it removes contaminants and impurities from wastewater before it is discharged back into the environment.

Overall, the 720S Wastewater Treatment Chain is a reliable and effective solution for treating wastewater. Its combination of advanced technologies and customizable design make it a valuable asset for any industry that produces wastewater.

Choose Our Malleable Casting Chains

RP Techniek BV is the Netherlands sales agent of Ever-power Group. We take pride in offering high-quality malleable cast iron chains, such as the 720S Wastewater Treatment Chain, which is designed to withstand harsh wastewater treatment environments. Our malleable casting chains are known for their unique selling points, including their durability, reliability, and exceptional performance.

Our company takes quality and customer service seriously. We ensure that our products meet the highest industry standards, and our team is always ready to provide prompt and efficient assistance to our clients. Our production capabilities are also top-notch, allowing us to manufacture and deliver our products quickly and efficiently to clients worldwide.

Aside from our malleable casting chains, we also offer various other types of casting chains for sale. Our extensive product range includes everything from standard chains to specialized chains for specific industries.

Sprockets for Sale

If you're in the market for a high-quality, durable sprocket to go with your 720S wastewater treatment chain, you've come to the right place. Our company offers a wide range of sprockets to fit any application, and we're confident that we have the perfect solution for your needs.

Not only do we offer a variety of sizes and tooth counts to ensure a perfect match with your chain, but we also provide sprockets made from a variety of materials, including steel, cast iron, and plastic. This allows us to meet the specific needs of each customer, whether you're looking for a heavy-duty sprocket for a rugged application or a lightweight sprocket for more sensitive equipment.

No matter what your requirements are, our team of experts has the knowledge and experience to help you find the perfect sprocket for your needs. And with our commitment to quality and customer satisfaction, you can trust that you'll be getting a top-of-the-line product that will provide reliable performance for years to come.

So if you're in the market for sprockets, look no further than our company. Contact us today to learn more about our wide range of sprocket options and how we can help you find the perfect solution for your needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...