In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

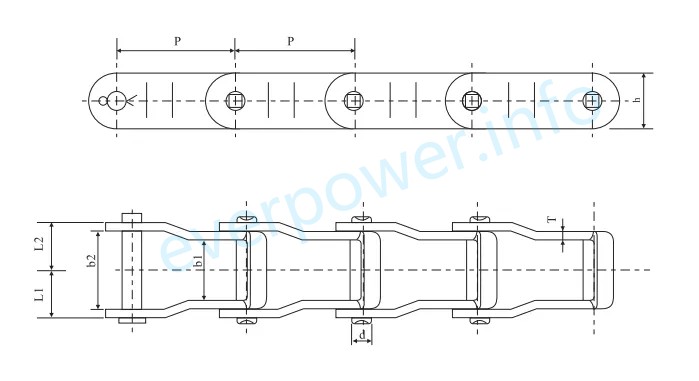

Specifications of 667X Stainless Steel Pintle Chain

Below are the specific parameters for the stainless steel pintle chains.

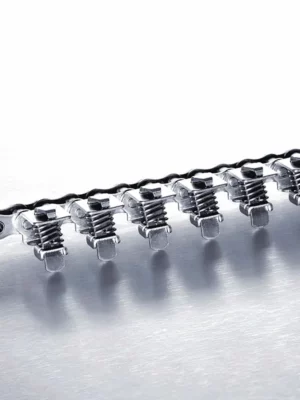

Introduction of 667X Stainless Steel Pintle Chain

This pintle chain, crafted from high-grade stainless steel, is engineered for exceptional durability and strength. Its corrosion and wear resistance ensures a prolonged lifespan. The innovative design of the chain allows for remarkable load-bearing capabilities and seamless operation, making it suitable for a range of industrial applications that demand dependable and efficient conveying systems.

Advantages of 667X Stainless Steel Pintle Chain

The 667X Stainless Steel Pintle Chain from our company boasts several benefits compared to other chain varieties. Its construction from stainless steel provides unmatched durability and resistance to corrosion, making it ideal for harsh or corrosive environments where other types might quickly deteriorate.

Moreover, the pintle design facilitates easy assembly and disassembly, simplifying maintenance and repairs. Its compact and low-profile design enables it to fit into limited spaces while maintaining high performance and reliability.

Whether you require the movement of heavy loads, operation in high temperatures, or functionality in corrosive settings, our 667X Stainless Steel Pintle Chain is the perfect solution. Don’t settle for less!

Applications of 667X Stainless Steel Pintle Chain

The 667X Stainless Steel Pintle Chain is a robust and efficient choice suitable for numerous applications. Below are some specific uses for this chain:

- Conveyor Systems: The 667X Stainless Steel Pintle Chain is perfectly designed for conveyor systems that must endure heavy loads and tough environments. Its stainless steel build guarantees durability and corrosion resistance, making it well-suited for the food and beverage, pharmaceutical, and chemical sectors.

- Paper Manufacturing: This chain is frequently employed in paper manufacturing where it is necessary to transport heavy paper rolls or sheets. Its strength and durability allow it to handle the weight of substantial paper rolls and function in elevated temperature conditions.

- Wastewater Treatment: It is also utilized in wastewater treatment facilities where exposure to corrosive materials occurs. The stainless steel construction allows it to withstand harsh environmental challenges and resist corrosion.

With its adaptability, the 667X Stainless Steel Pintle Chain is an excellent option across a variety of industries.

Maintenance Tips for 667X Stainless Steel Pintle Chain

To maintain optimal performance and extend the lifespan of your 667X stainless steel pintle chain, proper upkeep is essential. Here are some recommendations to keep your chain in excellent condition:

Cleaning:

It's vital to routinely clean your chain to prevent debris and dirt accumulation. A soft-bristled brush and a mild detergent solution work well for cleaning. Steer clear of harsh chemicals or abrasive materials that could harm the chain's surface.

Lubrication:

After cleaning, it’s important to lubricate your chain to ensure smooth functioning. Use a lubricant suitable for stainless steel, such as silicone-based or PTFE-based options. Apply the lubricant evenly across the chain, ensuring all moving parts are covered.

Inspection:

Conduct regular inspections of your chain for any signs of wear, such as elongation, corrosion, or damage to the pins, links, or rollers. If you observe any issues, replacing the chain is advisable to prevent potential malfunction during use.

By adhering to these maintenance guidelines, you can ensure that your 667X stainless steel pintle chain remains in prime condition and operates efficiently for an extended period.

Sprockets for Stainless Steel Chains

When selecting the appropriate sprockets for your 667X Stainless Steel Pintle Chain, several factors must be considered. Firstly, it’s essential to choose sprockets specifically engineered for stainless steel chains. These sprockets are crafted from high-quality materials that guarantee excellent corrosion resistance and durability, leading to a longer lifespan for your chains.

Another important consideration is the number of teeth on the sprockets. It is crucial that the number of teeth aligns with the pitch of the chain to ensure proper engagement and smooth operation. Consulting the manufacturer's specifications or seeking professional guidance is recommended to determine the optimal number of teeth for your application.

Our company provides a comprehensive selection of sprockets to accommodate different types of stainless steel chains. Whether you need standard sprockets, double-pitch sprockets, or custom options, we have solutions for you. Our sprockets are manufactured with precision and strict quality control to ensure maximum performance and dependability.

With our broad assortment of sprockets, you can find the perfect match for your 667X Stainless Steel Pintle Chain. Contact us today to explore our sprocket offerings and discuss your specific needs.

Why Choose Our Stainless Steel Pintle Chains?

The 667X Stainless Steel Pintle Chain stands out as an excellent option for a variety of industrial uses. At RP Techniek BV, we pride ourselves on providing high-quality products and exceptional services to our esteemed clients.

A significant advantage of our stainless steel pintle chains is their remarkable durability. Constructed from premium stainless steel, our chains exhibit excellent corrosion resistance, ensuring a prolonged lifespan and dependable performance in even the most challenging conditions.

In addition to their quality, our pintle chains are designed for smooth and efficient operation. With precise engineering and careful attention to detail, our chains provide optimal performance, minimizing downtime and enhancing productivity in your operations.

As the sales representative for Ever-power Group in the Netherlands, we are affiliated with a well-respected organization recognized for its expertise in power transmission solutions. This collaboration allows us to uphold the highest quality and reliability standards in our products.

Moreover, we offer a diverse array of other stainless steel roller chains to meet various industry requirements. Whatever your specific needs may be, we have the right chain solution for you.

Explore our collection of stainless steel pintle chains and witness the quality and service that distinguish us from the competition. Trust RP Techniek BV for all your stainless steel chain requirements.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...