In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications of 667J Stainless Steel Pintle Chain

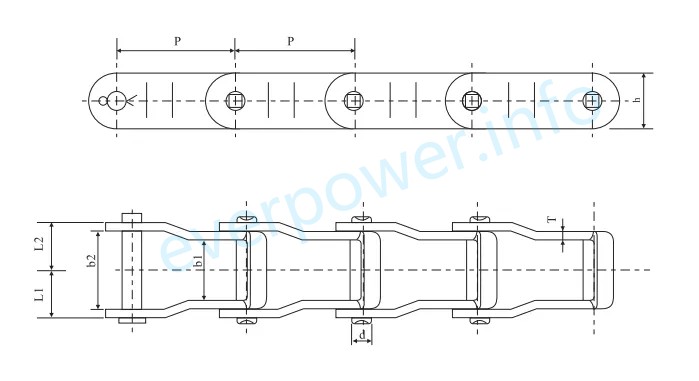

This section outlines the specific parameters of stainless steel pintle chains in detail.

Introduction of 667J Stainless Steel Pintle Chain

The 667J Stainless Steel Pintle Chain is designed for a range of industrial applications, featuring high-quality stainless steel construction that offers remarkable resistance to corrosion and increased longevity. Its robust build allows it to endure heavy loads and harsh operating conditions. This pintle chain delivers dependable performance, making it an excellent option for industries that demand efficient and reliable power transmission.

Advantages of 667J Stainless Steel Pintle Chain

The 667J Stainless Steel Pintle Chain presents several benefits compared to other chains available in the market. Its stainless steel design grants exceptional resistance to corrosion and rust, making it perfect for environments exposed to moisture or aggressive chemicals.

Furthermore, the 667J chain is built for strength, capable of managing heavy loads and meeting the challenges of the most demanding applications. This makes it a trusted choice for diverse industrial and agricultural environments.

The pintle design of the chain also provides unique advantages. Its open configuration promotes flexibility and facilitates easy maintenance, while the interlocking links guarantee a secure fit and smooth functionality. Additionally, it is compatible with various attachments, enhancing its versatility for multiple tasks.

In summary, if you seek a robust and long-lasting chain that can withstand difficult conditions, our 667J Stainless Steel Pintle Chain is an outstanding option. Refer to the image below for a visual overview of its features and design.

Applications of the 667J Stainless Steel Pintle Chain

The 667J Stainless Steel Pintle Chain is a multipurpose chain utilized across various industries. Here are several primary applications of this chain:

1. Food Processing Industry: The 667J Stainless Steel Pintle Chain is extensively used in food processing facilities due to its resistance to corrosion. It is ideal for the conveyance and transfer of food items, ensuring hygienic and dependable operations.

2. Packaging Machinery: This chain is particularly well-suited for packaging machinery, facilitating the movement of packaged products. Its strength and durability allow it to handle heavy loads in demanding environments.

3. Industrial Ovens and Furnaces: The 667J chain is commonly found in industrial ovens and furnaces, where high temperatures and challenging conditions prevail. Its stainless steel composition enables it to resist extreme heat while ensuring efficient operation.

4. Waste Water Treatment: In waste water treatment facilities, the 667J chain is employed in diverse applications, including dewatering systems, sludge conveyors, and grit removal setups. Its durability against corrosion and wear makes it suitable for such rigorous conditions.

5. Automotive Assembly Lines: This chain is also utilized in automotive assembly lines for transporting components and ensuring efficient production workflows. Its reliability and sturdiness are crucial for maintaining seamless operations.

Overall, the 667J Stainless Steel Pintle Chain is a reliable and versatile solution extensively used in food processing, packaging machinery, industrial ovens, waste water treatment, and automotive assembly lines.

Maintenance Recommendations for 667J Stainless Steel Pintle Chain

To maintain optimal performance and extend the lifespan of the 667J stainless steel pintle chain, proper maintenance is essential. Regular cleaning and lubrication are crucial for keeping the chain in excellent condition. Follow the steps below for effective cleaning and lubrication:

- Begin by eliminating any dirt, debris, or contaminants from the chain. Use a soft brush or cloth to gently clean the chain, focusing on areas with significant buildup.

- Once cleaned, thoroughly rinse the chain with water to eliminate any remaining residues.

- Dry the chain completely using a clean cloth or compressed air, ensuring no moisture remains on the surface.

- Apply a high-quality lubricant specifically formulated for stainless steel chains, selecting one that resists water, heat, and corrosion.

- Utilize a lubrication brush or spray to uniformly distribute the lubricant along the entire length of the chain, ensuring all inner links, rollers, and pins are covered.

- Wipe off any excess lubricant to prevent attracting dirt and debris.

It is recommended to establish regular maintenance intervals based on the chain's usage and operating environment. By following these maintenance guidelines, you can ensure that the 667J stainless steel pintle chain remains in peak condition, optimizing its performance and durability.

Sprockets for Stainless Steel Chains

When selecting the appropriate sprockets for your 667J Stainless Steel Pintle Chain, several factors should be taken into account. It is crucial to choose sprockets specifically designed for stainless steel chains to guarantee maximum durability and performance. Stainless steel sprockets resist corrosion, making them ideal for sectors such as food processing, chemical production, and pharmaceuticals.

Our company provides a diverse array of sprockets to accommodate various applications and needs. Our assortment includes single, double, and triple strand sprockets, in addition to taper lock and idler sprockets. Each type is meticulously designed to ensure reliable performance and an extended service life.

Manufactured from high-quality materials, our sprockets undergo stringent testing to confirm they meet the highest standards. With our wide range of sprockets, you can easily find the perfect fit for your 667J Stainless Steel Pintle Chain, ensuring smooth operation and minimizing chain wear.

Why Choose Our Stainless Steel Pintle Chains?

At RP Techniek BV, we pride ourselves on offering top-notch stainless steel pintle chains. Our 667J Stainless Steel Pintle Chain exemplifies this quality. With exceptional durability and strength, it serves as the perfect solution for a variety of industrial applications.

Our commitment to product excellence is one of our distinguishing features. Our stainless steel pintle chains undergo extensive testing to ensure they comply with the highest industry standards, ensuring their reliability and extended lifespan even in demanding conditions.

In addition to product quality, we emphasize outstanding customer service. Our dedicated team is always available to assist with any questions or concerns, providing prompt and knowledgeable support. We aim to foster long-lasting relationships with our customers based on trust and satisfaction.

Moreover, RP Techniek BV is the authorized sales representative for Ever-power Group in the Netherlands. This partnership enables us to provide a comprehensive selection of stainless steel roller chains, in addition to the 667J Stainless Steel Pintle Chain. With our extensive inventory, you are likely to find the ideal chain for your specific requirements.

Check out the image below to witness the quality and craftsmanship of our stainless steel pintle chains.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...