In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications of 667H Stainless Steel Pintle Chain

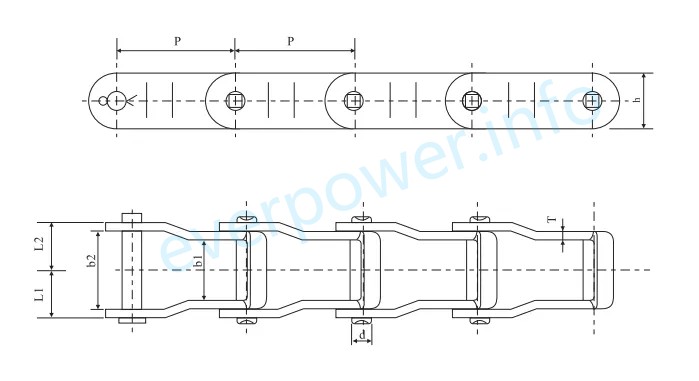

This segment outlines the specifications of stainless steel pintle chains.

Introduction of 667H Stainless Steel Pintle Chain

The 667H Stainless Steel Pintle Chain is known for its strength and reliability, making it suitable for a variety of industrial uses. Constructed from premium stainless steel, this chain provides outstanding resistance to both corrosion and wear. Its distinctive design allows for smooth functioning and effective power transmission. With its high-quality materials and remarkable performance, the 667H Stainless Steel Pintle Chain is an excellent option for challenging environments.

Advantages of 667H Stainless Steel Pintle Chain

We take pride in the exceptional quality of our 667H Stainless Steel Pintle Chain. The following are key benefits of using this dependable chain:

- Corrosion Resistance: Our 667H Stainless Steel Pintle Chain is crafted from high-grade stainless steel, allowing it to endure tough environments and resist corrosion over time.

- High Strength: Featuring robust construction, our 667H Stainless Steel Pintle Chain is capable of supporting heavy loads while maintaining its structural integrity under significant stress.

- Durability: Thanks to our rigorous quality control measures and advanced manufacturing methods, our 667H Stainless Steel Pintle Chain is designed to withstand demanding applications and environments.

Whether you require a dependable chain for a high-pressure manufacturing setting or a rugged outdoor environment, our 667H Stainless Steel Pintle Chain provides unmatched performance and longevity. Discover why countless customers rely on us for the best chain products in the market.

Applications of 667H Stainless Steel Pintle Chain

The 667H Stainless Steel Pintle Chain is a versatile option suitable for numerous industrial applications. Here are some specific uses for this chain:

- Conveyor Systems: The 667H Stainless Steel Pintle Chain is frequently utilized in conveyor systems across sectors like food processing, pharmaceuticals, and automotive. Its robust design and corrosion resistance make it an ideal choice for these applications.

- Packaging: This chain is also widely employed in packaging machinery to transport products through the packaging process. Its strength and durability ensure it can endure the demanding conditions of packaging equipment.

- Agriculture: The 667H Stainless Steel Pintle Chain is implemented in agricultural machinery, including combine harvesters and grain elevators. Its resistance to rust and corrosion makes it perfect for challenging environments.

In summary, the 667H Stainless Steel Pintle Chain is a reliable option for numerous industrial applications due to its strength, durability, and corrosion resistance. Below is an image showcasing this chain:

Maintenance of 667H Stainless Steel Pintle Chain

Regular maintenance is crucial for prolonging the lifespan and ensuring the efficiency of the 667H stainless steel pintle chain. Here are some maintenance tips:

- Periodically clean the chain to eliminate dirt, debris, and other contaminants that may cause degradation.

- Utilize a mild detergent and water for cleaning, avoiding harsh chemicals that may induce corrosion.

- Thoroughly dry the chain after cleaning to avert rust and corrosion.

- Examine the chain frequently for any signs of wear or damage, such as bent or broken links, and replace any damaged segments promptly.

- Lubricate the chain consistently with a high-quality lubricant to minimize friction and wear.

- Choose a lubricant that is specifically designed for stainless steel chains and apply it evenly across the chain.

By adhering to these maintenance guidelines, you can help ensure that your 667H stainless steel pintle chain operates at peak performance and enjoys a long service life. Here’s an image of the chain:

Sprockets for Stainless Steel Chains

When selecting the correct sprocket for the 667H Stainless Steel Pintle Chain, it is vital to take several factors into account. Key specifications such as pitch diameter, bore size, and tooth count must align with the chain. Additionally, the sprocket's material should be compatible with the stainless steel chain.

We offer an extensive range of sprockets designed to meet our customers' demands. Our sprockets come in various materials, including stainless steel and cast iron, to guarantee compatibility with different chains. Furthermore, we provide sprockets with diverse tooth counts to accommodate varying speeds and torque requirements.

Whether you require a standard sprocket or a custom solution, our experienced team is ready to assist you in finding the ideal sprocket for your specific needs. Reach out to us today to explore our sprocket options and learn how we can support your chain drive requirements.

Why Choose Our Stainless Steel Pintle Chains?

Our 667H Stainless Steel Pintle Chain exemplifies our company’s unique selling points. We take pride in delivering outstanding quality in our products and exceptional customer service. With a dedication to excellence, we ensure that our stainless steel pintle chains comply with the highest industry standards.

What differentiates us from competitors is our commitment to providing reliable and long-lasting products. Our stainless steel pintle chains are produced using high-quality materials, making them resistant to both corrosion and wear, resulting in enhanced durability and reduced maintenance costs for our clients.

As the Dutch sales representative for Ever-power Group, RP Techniek BV is honored to represent a well-respected brand recognized for its superior engineering and manufacturing capabilities. We are committed to offering a comprehensive selection of stainless steel roller chains, in addition to the 667H Pintle Chain, effectively catering to various industrial needs and applications.

We understand that each customer has distinct requirements, and our knowledgeable team is always available to offer personalized support. Whether you need assistance in selecting the appropriate chain for your specific application or require technical support, we are here to help.

To provide you with a glimpse of our offerings, we have included an image below:

Contact us today to experience the reliability, durability, and outstanding quality of our stainless steel pintle chains and related products. We eagerly anticipate the opportunity to serve you and exceed your expectations.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...