Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

60 Weld on Sprockets

The 60 Weld on Sprockets and Hubs are essential components for various machinery, designed for durability and high performance. These sprockets pair seamlessly with the Weld-on Hubs series, ensuring reliable connections and efficient power transmission in industrial applications.

Types and Sizes of 60 Weld on Sprockets and Hubs

| No.Teeth | 60 |

| 3/4" Pitch | |

| 9 | 60V9 |

| 10 | 60V10 |

| 11 | 60V11 |

| 12 | 60W12 |

| 13 | 60W13 |

| 14 | 60W14 |

| 15 | 60W15 |

| 16 | 60X16 |

| 17 | 60X17 |

| 18 | 60X18 |

| 19 | 60X19 |

| 20 | 60X20 |

| 21 | 60X21 |

| 22 | 60X22 |

| 23 | 60X23 |

| 24 | 60X24 |

| 25 | 60X25 |

| 26 | 60X26 |

| 27 | 60X27 |

| 28 | 60X28 |

| 29 | 60X29 |

| 30 | 60X30 |

| 31 | 60X31 |

| 32 | 60X32 |

| 33 | 60X33 |

| 34 | 60X34 |

| 35 | 60X35 |

| 36 | 60X36 |

| 37 | 60X37 |

| 38 | 60X38 |

| 39 | 60X39 |

| 40 | 60X40 |

| 42 | 60X42 |

| 43 | 60X43 |

| 44 | 60X44 |

| 45 | 60X45 |

| 48 | 60X48 |

| 50 | 60X50 |

| 54 | 60X54 |

| 60 | 60X60 |

| 70 | 60X70 |

| 72 | 60X72 |

| 80 | 60X80 |

| 84 | 60X84 |

| 96 | 60X96 |

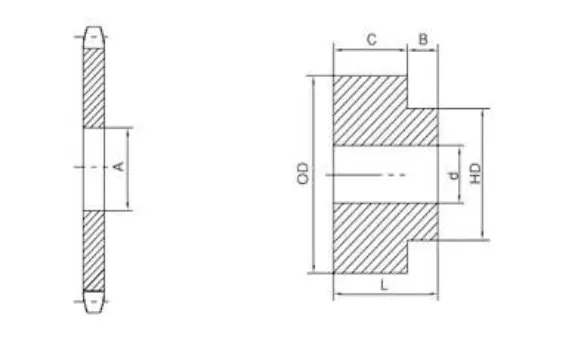

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | A |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | 1-1/8 |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | 1-5/8 |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | 2 |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | 2 |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | 2-3/4 |

Applications of 60 Weld on Sprockets and Hubs

The 60 Weld on Sprockets and Hubs are widely used in various industries, including manufacturing, agriculture, and automotive. They are ideal for applications requiring robust power transmission systems, such as conveyor belts, agricultural machinery, and custom machinery builds. Their durability and versatility make them suitable for both heavy-duty and precision tasks, ensuring efficiency in your operations.

Installation of 60 Weld on Sprockets and Hubs

To install the 60 Weld on Sprockets and Hubs, follow these steps:

- Ensure the surface is clean and free from rust or debris.

- Align the sprocket with the hub, ensuring proper fit.

- Secure the sprocket in place using clamps or fixtures.

- Weld around the perimeter, maintaining consistent heat to prevent warping.

- Allow the assembly to cool before removing clamps.

Check for proper alignment and functionality before use.

How to Choose the Right Weld on Sprockets and Hubs

When selecting the appropriate weld on sprockets and hubs, consider the following steps:

- Determine the Application: Assess the specific needs of your machinery or project.

- Size and Compatibility: Measure the dimensions and ensure compatibility with existing components.

- Material Selection: Choose durable materials that can withstand the operational environment.

- Load Capacity: Evaluate the load requirements to select sprockets and hubs that can handle the stress.

- Consult Manufacturer Specifications: Review technical data sheets for detailed information.

Weld on Sprockets and Hubs for Sale in Netherlands

RP Techniek BV is the Dutch sales agent for Ever-power Group and is recognized as one of the top sprocket suppliers in the Netherlands. Our extensive range of products includes 60 different types of weld on sprockets and hubs, catering to various industrial needs. Each sprocket is engineered for durability and performance, ensuring optimal compatibility with your machinery. Our commitment to quality means that you can rely on our products for your operational efficiency.

In addition to supplying high-quality sprockets, we pride ourselves on providing exceptional customer service. Our knowledgeable team is always ready to assist you with any inquiries and ensure that you find the perfect solution for your requirements.

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...