In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

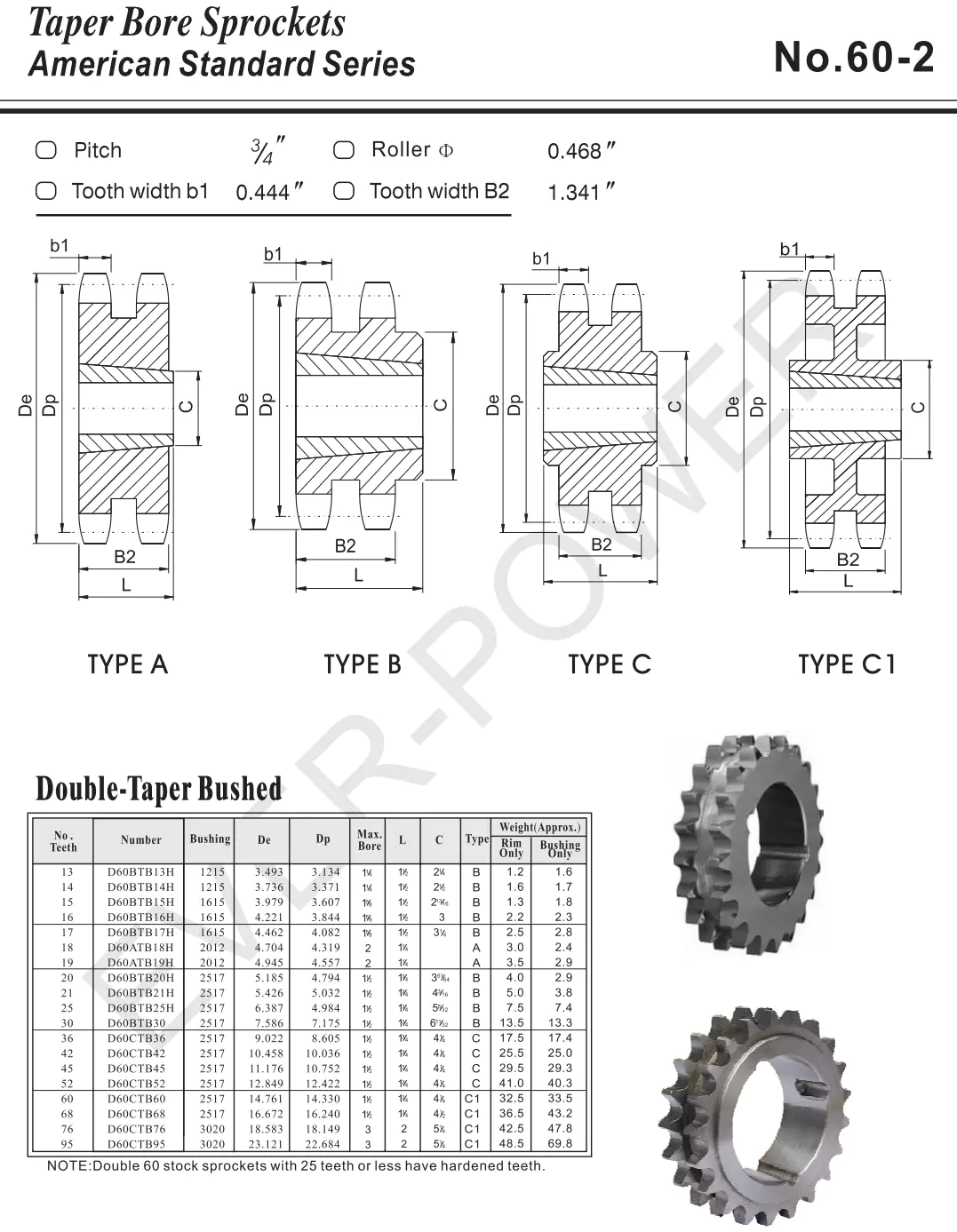

#60-2 3/4″ Taper Bore Sprocket

The #60-2 3/4″ Taper Bore Sprocket is engineered for durability and precision in power transmission systems. Its taper bore design allows for easy installation on various shafts, ensuring a secure fit. Ideal for industrial applications, this sprocket delivers reliable performance and efficiency in demanding environments.

#60-2 3/4" Taper Bore Sprocket Specifications

The #60-2 3/4" Taper Bore Sprocket is a crucial component widely used in power transmission systems. It features a specialized tapered bushing that allows for effortless installation and removal from the shaft. This design minimizes the risk of damaging either the sprocket or the shaft during the process. The ability to easily attach and detach the sprocket significantly enhances maintenance efficiency, making this component a favored choice in various applications.

Definition and Basic Structure

A taper bore sprocket is a particular kind of sprocket that utilizes a tapered bushing for secure attachment to a shaft. It is characterized by teeth that engage with a chain, facilitating power transmission, and a hub that connects the sprocket to the shaft. The tapered bushing is positioned on the shaft and then tightened, ensuring the sprocket remains securely in place during operation.

Features and Functions

- Easy installation: The tapered bushing design allows for straightforward and quick installation of the sprocket onto the shaft, significantly reducing downtimes during setup.

- High precision positioning: This tapered bushing guarantees that the sprocket is positioned accurately on the shaft, which is essential for smooth and efficient power transmission without unnecessary wear.

- Wide applicability: Taper bore sprockets are versatile and can be adapted to a wide range of shaft sizes, making them suitable for numerous power transmission applications across industries.

- Reliability: The taper lock mechanism ensures a secure and stable connection between the sprocket and the shaft, providing confidence in their operational integrity.

- Low maintenance cost: The uncomplicated installation and removal process associated with taper bore sprockets lead to lower maintenance costs and time savings.

The convenience of the taper bore sprocket's installation and removal is a significant advantage. Its tapered bushing design eliminates the need for additional keyways, set screws, or locking devices, streamlining the overall installation process and enhancing efficiency in operations.

Installation and Removal Process

Installing and removing a taper bore sprocket involves several clear steps to ensure proper handling:

- Prepare tools and materials: Collect a torque wrench, a socket set, and a clean cloth, as these will be essential for the proper installation or removal of the taper bore sprocket.

- Clean shaft and sprocket surface: It is vital to ensure that both the shaft and sprocket surfaces are clean, free from debris, or any contaminants that could interfere with the installation or performance.

- Place taper lock bushing: Slide the taper lock bushing onto the shaft, ensuring that it is properly seated and all screws are tightened to the manufacturer-recommended torque specifications.

- Install sprocket: Carefully slide the sprocket onto the bushing, making sure to align the keyway, if present, with the key on the shaft for secure engagement.

- Tighten locking nut: Use a torque wrench to fasten the locking nut to the specified torque value, ensuring a secure fit.

Sprockets Supplier in Netherlands

RP Techniek BV is the sales representative for Ever-power Group in the Netherlands, recognized for their high-quality sprockets and related products. Our #60-2 3/4" Taper Bore Sprocket is engineered for durability and efficiency, making it an indispensable component in various industrial applications. We take pride in delivering exceptional products that adhere to rigorous quality standards, ensuring optimal performance in all mechanical systems.

In addition to our standard sprockets, we provide customized solutions tailored to meet our clients' specific needs. Whether you require a unique size or a different configuration, our team is ready to assist you in developing custom sprockets based on your specifications and samples. We invite customers to contact us with their requirements for a personalized solution.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...