Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications for 52 Casting Detachable Chain

The following are the parameters of the 52 Casting Detachable Chain:

| CHAIN NO. | PITCH IN INCHES |

HEIGHT PER FOOT LBS |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | ?F | H | ?L | X | AVAILABLE ATTACHMENTS |

| 25 | 0.902 | 2.4 | 700 | 120 | 0.38 | 0.14 | ¡ª¡ª | 0.20 | ?0.78 | 0.41 | A1-R.A1-L | ||

| 32 | 1.154 | 3.5 | 1,100 | 185 | 0.50 | 0.17 | ¡ª¡ª | 0.25 | ?0.97 | 0.58 | A1-R.A1-L.K1 | ||

| 34 | 1.398 | 4.0 | 1.300 | 220 | 0.50 | 0.19 | 1.25 | 0.56 | None | ||||

| 42 | 1.375 | 5.5 | 1.600 | 270 | 0.62 | 0.22 | ¡ª¡ª | 0.28 | 1.28 | 0.77 | A1-R,A1-L.K1 | ||

| 45 | 1.630 | 5.2 | 1.700 | 285 | 0.69 | 0.22 | ¡ª¡ª | 0.30 | ?1.31 | 0.80 | A1-R.A1-L.K1 | ||

| 50 | 1.381 | 7.1 | 1.900 | 320 | 0.63 | 0.27 | 0.33 | ?1.31 | 0.62 | None | |||

| 51 | 1.155 | 7.0 | 1.900 | 320 | 0.56 | 0.27 | ¡ª¡ª | 0.36 | ?1.25 | 0.67 | K1 | ||

| S51 | 1.136 | 7.B | 1.900 | 315 | 0.56 | 0.27 | ¡ª¡ª | 0.30 | ?1.06 | 0.64 | None | ||

| 52 | 1.506 | 8.0 | 2,300 | 385 | 0.62 | 0.27 | ¡ª¡ª | 0.34 | ?1.53 | 0.83 | A1.D5,K1 | ||

| 55 | 1.631 | 7.2 | 2,300 | 385 | 0.69 | 0.27 | ¡ª¡ª | 0.36 | ?1.41 | 0.81 | A1-R/L,D5-R/L,C1.F2,G27-R/L,K1,C | ||

| 57 | 2.308 | 8.7 | 2.900 | 485 | 0.75 | 0.27 | ¡ª¡ª | 0.41 | ?1.81 | 1.09 | A1-R,A1-L.F2 | ||

| 62 | 1.654 | 10.6 | 3.200 | 535 | 0.81 | 0.31 | 0.41 | ?1.66 | 0.97 | A1-R/L,A12-R/L,05-R/L.K1,K2,F2 | |||

| 67 | 2.308 | 8.6 | 2.900 | 485 | 0.69 | 0.31 | ?0.53 | 0.41 | ?2.03 | 1.36 | None | ||

| 75 | 2.609 | 13.4 | 4,100 | 690 | 0.94 | 0.41 | ¡ª¡ª | 0.44 | ?2.09 | 1.12 | D5-R.D5-L | ||

| 77 | 2.297 | 14.5 | 3.600 | 600 | 0.69 | 0.39 | ?0.61 | 0.36 | ?2.22 | 1.42 | A1-R.A1-L.D5.F2,K1 | ||

| 78 | 2.609 | 18.8 | 5.500 | 920 | 0.94 | 0.42 | ?0.66 | 0.44 | ?2.62 | 1.62 | K1 | ||

| 88 | 2.609 | 24.0 | 6.400 | 1,070 | 0.94 | 0.48 | ?0.78 | 0.44 | ?2.75 | 1.78 | F2.K1 | ||

| 103 | 3.075 | 40.0 | 10,000 | 1,670 | 1.12 | 0.58 | ?1.00 | 0.61 | ?3.28 | 2.03 | F2.F8,K1,K2,F2 | ||

| 114 | 3.250 | 53.0 | 12.000 | 2.000 | 1.13 | 0.66 | ?0.17 | 0.81 | ?3.28 | 2.03 | None | ||

| 124 | 4.063 | 66.0 | 17.000 | 2,830 | 1.25 | 0.77 | ?1.31 | 0.68 | ?4.06 | 2.31 | F8.K1,K2 |

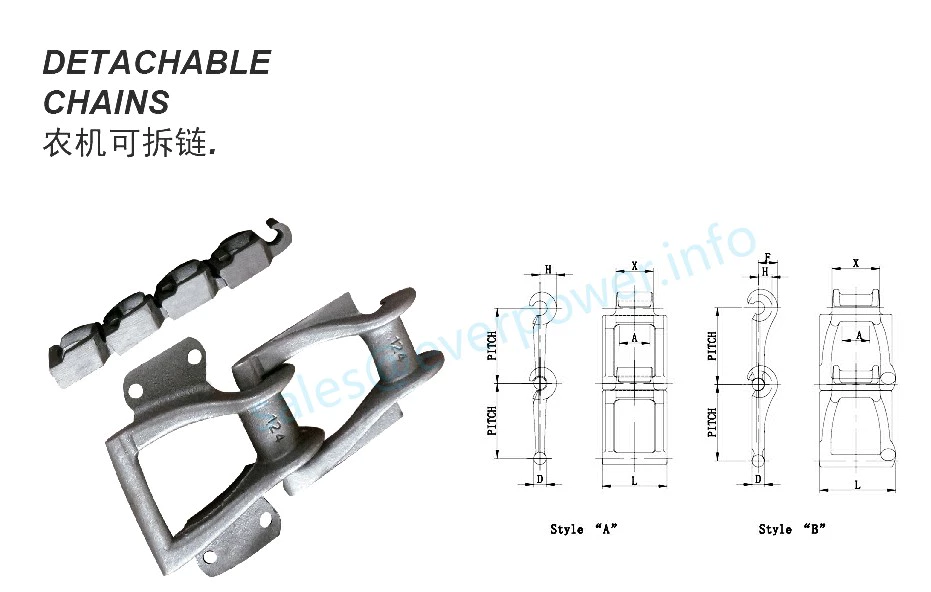

Overview of 52 Casting Detachable Chain

The 52 Casting Detachable Chain is a high-quality chain used in various applications such as power transmission, conveyor systems, and material handling. The chain is designed with detachable links, which makes it easy to install and maintain. It is made of high-strength materials such as alloy steel and is suitable for heavy-duty operations.

Features of 52 Casting Detachable Chain

- Detachable Links: The chain is designed with detachable links, which makes it easy to install and maintain.

- High Strength: The chain is made of high-strength materials such as alloy steel, which makes it suitable for heavy-duty operations.

- Durable: The chain is designed to withstand wear and tear, which makes it durable and long-lasting.

- Wide Application: The chain is suitable for various applications such as power transmission, conveyor systems, and material handling.

- Easy to Replace: The detachable links make it easy to replace the damaged links, which saves time and money.

Specifications of 52 Casting Detachable Chain

The 52 Casting Detachable Chain has the following specifications:

- Pitch: 63.50 mm

- Plate Thickness: 12.70 mm

- Breaking Load: 189 kN

- Weight per meter: 28.6 kg

Applications of 52 Casting Detachable Chain

The 52 Casting Detachable Chain is suitable for the following applications:

- Power Transmission: The chain is used to transmit power between machines.

- Conveyor Systems: The chain is used in conveyor systems to move materials from one place to another.

- Material Handling: The chain is used in material handling equipment such as bucket elevators and grain augers.

Maintenance of 52 Casting Detachable Chain

The 52 Casting Detachable Chain requires regular maintenance to ensure its optimal performance. The following maintenance practices are recommended:

- Inspect the chain regularly for signs of wear and tear.

- Replace the damaged links immediately to prevent further damage.

- Keep the chain lubricated to reduce friction and wear.

- Store the chain in a dry and cool place to prevent rust and corrosion.

Conclusion

The 52 Casting Detachable Chain is a high-quality chain that is suitable for heavy-duty operations. Its detachable links make it easy to install and maintain, and its high-strength materials make it durable and long-lasting. It is suitable for various applications such as power transmission, conveyor systems, and material handling. Regular maintenance is required to ensure its optimal performance and longevity.

Choose Our Malleable Casting Chains

RP Techniek BV is the Dutch sales agent of Ever-power Group. Our company takes pride in offering high-quality malleable cast iron chains, specifically the 52 Casting Detachable Chain.

Our malleable cast iron chains possess unique selling points that set them apart. They are known for their exceptional durability, reliability, and excellent performance. We prioritize delivering products of the highest quality to our customers, ensuring their satisfaction.

In addition to the 52 Casting Detachable Chain, we have a wide range of other casting chains available for sale. These chains come in various types, catering to different needs and applications. Whether you require chains for heavy-duty industrial use or for lighter applications, we have the perfect solution for you.

At RP Techniek BV, we pride ourselves on our strong manufacturing capabilities. With state-of-the-art facilities and a highly skilled team, we ensure that our casting chains are produced to the highest standards. We continuously strive for excellence in both product quality and customer service.

Please refer to the image below to get a glimpse of our chain manufacturing process:

Sprockets for Sale

When it comes to pairing with the 52 Casting Detachable Chain, we offer a wide range of suitable sprockets. Our company provides various types of sprockets for sale, ensuring that you can find the perfect match for your needs.

Whether you require a smaller sprocket for high-speed applications or a larger one for heavy-duty tasks, we have you covered. Our sprockets are manufactured using high-quality materials, ensuring durability and long-lasting performance.

With our extensive selection, you can choose from different sizes, tooth counts, and configurations to meet your specific requirements. We understand the importance of finding the right sprocket for efficient power transmission, and our knowledgeable team is here to assist you in making the best choice.

For more information on our range of sprockets and to explore our complete catalog, please visit our website. Don't miss out on the opportunity to enhance your machinery's performance with our top-notch sprockets.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...