Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

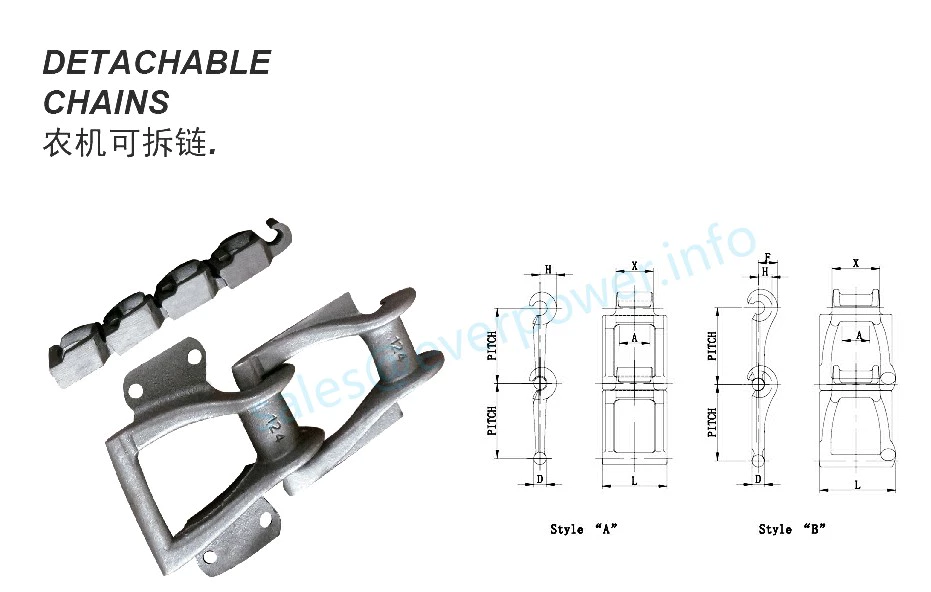

Specifications for 51 Casting Detachable Chain

- Material: Cast Iron

- Pitch: 63.5mm

- Width: 38.1mm

- Height: 74.6mm

- Thickness: 10.3mm

- Weight: 2.5kg/m

| CHAIN NO. | PITCH IN INCHES |

HEIGHT PER FOOT LBS |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | ?F | H | ?L | X | AVAILABLE ATTACHMENTS |

| 25 | 0.902 | 2.4 | 700 | 120 | 0.38 | 0.14 | ¡ª¡ª | 0.20 | ?0.78 | 0.41 | A1-R.A1-L | ||

| 32 | 1.154 | 3.5 | 1,100 | 185 | 0.50 | 0.17 | ¡ª¡ª | 0.25 | ?0.97 | 0.58 | A1-R.A1-L.K1 | ||

| 34 | 1.398 | 4.0 | 1.300 | 220 | 0.50 | 0.19 | 1.25 | 0.56 | None | ||||

| 42 | 1.375 | 5.5 | 1.600 | 270 | 0.62 | 0.22 | ¡ª¡ª | 0.28 | 1.28 | 0.77 | A1-R,A1-L.K1 | ||

| 45 | 1.630 | 5.2 | 1.700 | 285 | 0.69 | 0.22 | ¡ª¡ª | 0.30 | ?1.31 | 0.80 | A1-R.A1-L.K1 | ||

| 50 | 1.381 | 7.1 | 1.900 | 320 | 0.63 | 0.27 | 0.33 | ?1.31 | 0.62 | None | |||

| 51 | 1.155 | 7.0 | 1.900 | 320 | 0.56 | 0.27 | ¡ª¡ª | 0.36 | ?1.25 | 0.67 | K1 | ||

| S51 | 1.136 | 7.B | 1.900 | 315 | 0.56 | 0.27 | ¡ª¡ª | 0.30 | ?1.06 | 0.64 | None | ||

| 52 | 1.506 | 8.0 | 2,300 | 385 | 0.62 | 0.27 | ¡ª¡ª | 0.34 | ?1.53 | 0.83 | A1.D5,K1 | ||

| 55 | 1.631 | 7.2 | 2,300 | 385 | 0.69 | 0.27 | ¡ª¡ª | 0.36 | ?1.41 | 0.81 | A1-R/L,D5-R/L,C1.F2,G27-R/L,K1,C | ||

| 57 | 2.308 | 8.7 | 2.900 | 485 | 0.75 | 0.27 | ¡ª¡ª | 0.41 | ?1.81 | 1.09 | A1-R,A1-L.F2 | ||

| 62 | 1.654 | 10.6 | 3.200 | 535 | 0.81 | 0.31 | 0.41 | ?1.66 | 0.97 | A1-R/L,A12-R/L,05-R/L.K1,K2,F2 | |||

| 67 | 2.308 | 8.6 | 2.900 | 485 | 0.69 | 0.31 | ?0.53 | 0.41 | ?2.03 | 1.36 | None | ||

| 75 | 2.609 | 13.4 | 4,100 | 690 | 0.94 | 0.41 | ¡ª¡ª | 0.44 | ?2.09 | 1.12 | D5-R.D5-L | ||

| 77 | 2.297 | 14.5 | 3.600 | 600 | 0.69 | 0.39 | ?0.61 | 0.36 | ?2.22 | 1.42 | A1-R.A1-L.D5.F2,K1 | ||

| 78 | 2.609 | 18.8 | 5.500 | 920 | 0.94 | 0.42 | ?0.66 | 0.44 | ?2.62 | 1.62 | K1 | ||

| 88 | 2.609 | 24.0 | 6.400 | 1,070 | 0.94 | 0.48 | ?0.78 | 0.44 | ?2.75 | 1.78 | F2.K1 | ||

| 103 | 3.075 | 40.0 | 10,000 | 1,670 | 1.12 | 0.58 | ?1.00 | 0.61 | ?3.28 | 2.03 | F2.F8,K1,K2,F2 | ||

| 114 | 3.250 | 53.0 | 12.000 | 2.000 | 1.13 | 0.66 | ?0.17 | 0.81 | ?3.28 | 2.03 | None | ||

| 124 | 4.063 | 66.0 | 17.000 | 2,830 | 1.25 | 0.77 | ?1.31 | 0.68 | ?4.06 | 2.31 | F8.K1,K2 |

Overview

The 51 Casting Detachable Chain is an essential component in the manufacturing industry, particularly in conveyor systems where materials are transported from one place to another.

Structure

The chain is constructed using high-quality materials such as carbon steel or alloy steel, which provide strength, durability, and resistance to wear and tear. It features a detachable design, which allows for easy installation and maintenance.

Applications

The 51 Casting Detachable Chain is widely used in various industries, including automotive, food processing, agriculture, and mining. It is suitable for conveying heavy materials such as grains, coal, and chemicals.

Advantages

Compared to other types of chains, the 51 Casting Detachable Chain has several advantages. Firstly, its detachable design allows for quick and easy repairs or replacement of damaged links. Secondly, the use of high-quality materials makes it resistant to wear and corrosion. Finally, its ability to handle heavy loads makes it ideal for use in rugged environments.

Maintenance

Proper maintenance is crucial in ensuring the longevity and optimal performance of the 51 Casting Detachable Chain. Regular inspection and lubrication are recommended to prevent rust and ensure smooth operation. Additionally, any damaged links should be promptly replaced to avoid potential hazards.

Customization

The 51 Casting Detachable Chain can be customized according to specific industry requirements. This includes variations in pitch, chain width, and material composition. Customization ensures that the chain is optimized for the particular application, resulting in improved efficiency and productivity.

Choose Our Malleable Casting Chains

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We take pride in offering high-quality malleable casting chains, including the impressive 51 Casting Detachable Chain.

Our malleable cast iron chains are known for their unique selling points, including exceptional product quality, outstanding customer service, and unparalleled production capabilities. We understand the importance of providing reliable and durable products to our customers, and our chains are no exception.

In addition to our malleable casting chains, we also offer a wide variety of other casting chains for sale. Our selection includes different types of chains, each with their own unique features and benefits.

At RP Techniek BV, we are committed to providing our customers with the best possible products and services. Our team of experts is always ready to assist you with any questions or concerns you may have, and we strive to deliver your orders in a timely and efficient manner.

Order our malleable casting chains today and experience the quality and reliability that RP Techniek BV and Ever-power Group are known for.

Sprockets for Sale

When it comes to finding the perfect match for your 51 Casting Detachable Chain, look no further than our wide range of sprockets. We offer a diverse selection of chain wheels that are specifically designed to provide optimal performance and durability.

Our company takes pride in offering various types of sprockets for sale, ensuring that you can find the right fit for your specific needs. Whether you require a standard roller chain sprocket, a specialty sprocket, or a custom-made sprocket, we have got you covered.

With our high-quality sprockets, you can expect smooth and efficient power transmission, reducing wear and tear on your chain. Our sprockets are precision-engineered to meet industry standards, guaranteeing long-lasting performance and reliability.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...