In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

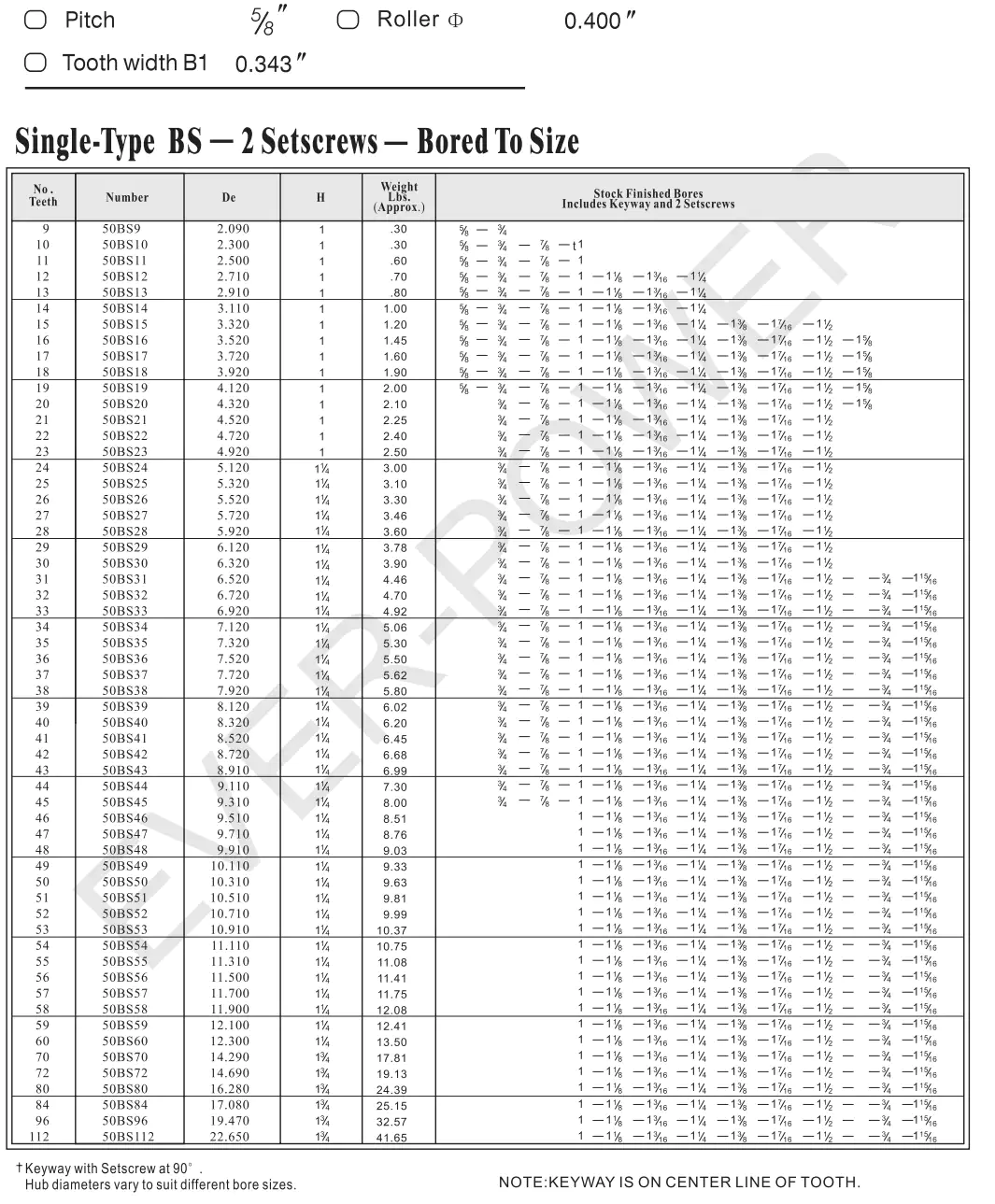

50BS* Finished Bore Sprocket

The 50BS* Finished Bore Sprocket is engineered for optimal performance and durability in various applications. With a precision-finished bore, it ensures a secure fit on your drive shaft, minimizing wear and tear. This high-quality sprocket is ideal for heavy-duty use, providing reliable power transmission and enhancing overall machine efficiency.

Specifications of 50BS* Finished Bore Sprocket

The 50BS* Finished Bore Sprocket is engineered for optimal performance, featuring a pre-bored hole and keyway that facilitate easy installation. This premium-quality sprocket is widely used across numerous industrial applications. Key specifications include:

- Material: Constructed from high-quality materials such as high carbon steel, alloy steel, or stainless steel, ensuring exceptional durability and a long operational lifespan.

- Manufacturing Process: Our manufacturing approach involves a combination of advanced techniques, including cutting, stamping, forging, CNC machining, heat treatment, surface hardening, and comprehensive quality inspections to uphold rigorous manufacturing standards.

Finished Bore Sprockets Applications

This finished bore sprocket is particularly suited for heavy-duty applications, such as:

- Heavy machinery and equipment

- Food processing and packaging

- Chemical and pharmaceutical industries

- Assembly lines

- Logistics and warehousing

Maintenance and Troubleshooting

Consistent maintenance and regular inspections are essential for the effective functioning of your sprocket. Here are some critical maintenance recommendations to follow:

- Daily Inspection: Regularly check the sprocket for any visible damage, wear, or misalignment. This practice can prevent potential operational failures.

- Cleaning: Keeping the sprocket clean is vital. Utilize appropriate cleaning methods to remove dirt, debris, and contaminants that could potentially harm the sprocket’s performance and longevity.

- Lubrication: Proper lubrication plays a significant role in reducing friction and wear. Ensure you use high-quality lubricants that are compatible with the sprocket's material to maximize its lifespan.

- Adjustment and Calibration: Regularly verify that the sprocket is properly adjusted and calibrated to avoid issues such as misalignment or slippage during operation.

Finished Bore Sprocket Common Issues and Solutions

Common issues that can arise with your sprocket include:

- Skipping teeth

- Breakage

- Wear and tear

- Noise

- Chain slipping off

In case you encounter any of these problems, it is crucial to take prompt action to prevent further damage. Here are suggested resolutions for typical sprocket issues:

- Skipping teeth: Inspect the sprocket for worn chains or damaged teeth, and replace any necessary components to restore functionality.

- Breakage: Evaluate the sprocket for signs of excessive wear or damage, and replace it if required to maintain operational efficiency.

- Wear and tear: Conduct regular inspections to identify signs of wear and replace the sprocket when necessary to ensure reliable performance.

- Noise: Investigate potential misalignment or inadequate lubrication and make necessary adjustments or lubrication to alleviate the issue.

- Chain slipping off: Check for misalignment or damage to the sprocket and chain, and make appropriate adjustments or replacements as needed.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, presenting a diverse array of high-quality sprockets tailored to meet various industrial requirements. One of our standout offerings is the 50BS* Finished Bore Sprocket, celebrated for its durability and precision engineering. Designed for optimal performance in power transmission tasks, this sprocket ensures reliability and efficiency in your operations.

Beyond our standard offerings, we also provide non-standard customization options according to customer specifications. We encourage clients to share their designs or samples with us so we can deliver tailored solutions that align with their unique needs. Our commitment to customer satisfaction guarantees that you will receive the highest quality products and services available in the industry.

Thank you for considering our finished bore sprocket for your industrial applications.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...