In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

#50 Chain Idler Sprocket

The #50 Chain Idler Sprocket is a crucial component designed to optimize the performance of chain-driven systems. Primarily used in conveyor belts, agricultural machinery, and automotive applications, this sprocket helps maintain proper chain tension and alignment, reducing wear and extending the lifespan of both the chain and sprocket. Its durable construction ensures reliability in demanding environments.

#50 Chain Idler Sprocket Parameters

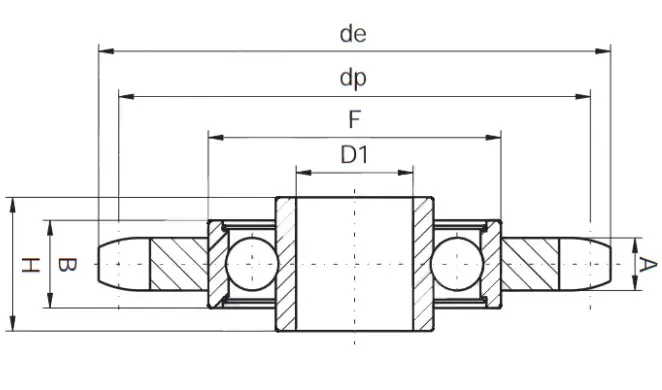

Ball Bearing Idler Sprockets

|

|

| Z | Pitch | de | dp | A | D1 | F | B | H | Chain Size |

| 14 | 5/8"×3/8" | 78 | 71.34 | 9.1 | 16 | 40 | 12 | 18.3 | #50 |

| 15 | 5/8"×3/8" | 83 | 76.36 | 9.1 | 16 | 40 | 12 | 18.3 | #50 |

| 17 | 5/8"×3/8" | 93 | 86.39 | 9.1 | 16 | 40 | 12 | 18.3 | #50 |

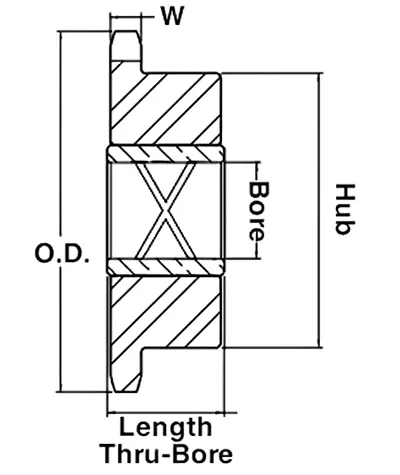

Needle Bearing Idler Sprockets

|

|

| Sprocket Size | Number Of Teeth | Bearing Type | Chain Size | Outside Diameter | Bore Size | Length Thru Bore | Dimension (T) | Hub Diameter | Weight |

| 50NB17H | 17 | Needle Bearing | #50 | 3.72" | 1.00" | 1.00" | 0.343" | 2.25" | 1.30 LBS |

Bronze Bearing Idler Sprockets

|

|

| Sprocket Size | Number Of Teeth | Bearing Type | Chain Size | Outside Diameter | Bore Size | Length Thru Bore | Dimension (T) | Hub Diameter | Weight |

| 50BR13 | 13 | Bronze Bearing | #50 | 2.91" | 1/2" | 0.94" | 0.343" | 1.87" | 0.90 LBS |

| 50BR17 | 17 | Bronze Bearing | #50 | 3.72" | 7/8" | 1.06" | 0.343" | 2.62" | 1.50 LBS |

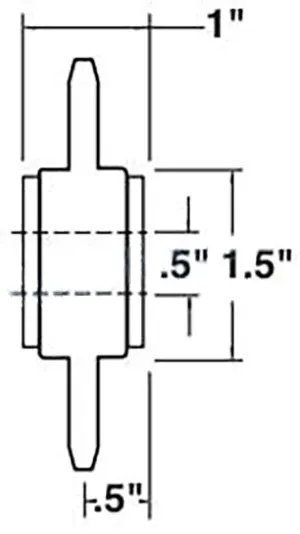

Bronze Bushed Idler Sprockets

|

|

| Sprocket Size | Number Of Teeth | Chain Size | Outside Diameter | Bore Size | Weight |

| 51E15 | 15 | #50 | 3.32" | 1/2" | 0.70 LBS |

#50 Chain Idler Sprocket Features

- Durable Construction: Made from high-quality materials for long-lasting performance.

- Precision Engineering: Designed for optimal compatibility with #50 chains, ensuring smooth operation.

- Easy Installation: User-friendly design allows for quick and hassle-free setup.

- Versatile Applications: Suitable for various machinery and equipment, enhancing functionality.

- Low Maintenance: Requires minimal upkeep, saving time and costs in the long run.

Applications of #50 Chain Idler Sprocket

The #50 Chain Idler Sprocket is widely utilized across various industries, including:

- Agriculture: Used in farm machinery for efficient power transfer.

- Manufacturing: Essential in conveyor systems to maintain smooth operations.

- Automotive: Found in various vehicle assemblies for enhanced performance.

- Construction: Employed in heavy equipment to support chain-driven applications.

Its versatility makes it ideal for numerous mechanical systems requiring durable and reliable performance.

Different Idler Sprocket Types

The #50 Chain Idler Sprocket comes in various bearing types, each offering unique advantages. Ball bearing idler sprockets provide smooth operation and durability, while needle bearing types allow for higher load capacities and reduced friction. Bronze bearing idler sprockets, on the other hand, excel in high-temperature environments, offering excellent wear resistance. Choose the right type for your specific application needs.

Idler Sprockets Manufacturer in Holland

RP Techniek BV is the Dutch sales agent for Ever-power Group, and we are one of the top sprocket suppliers in the Netherlands. We specialize in providing high-quality idler sprockets, including the #50 Chain Idler Sprocket, designed to meet the rigorous demands of various applications. Our commitment to excellence ensures that our products are not only durable but also reliable, making us a preferred choice for many businesses.

In addition to our extensive range of standard products, we also offer non-standard customization services tailored to meet specific customer requirements. We welcome our customers to bring their designs or samples for bespoke solutions that perfectly fit their needs.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...