In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

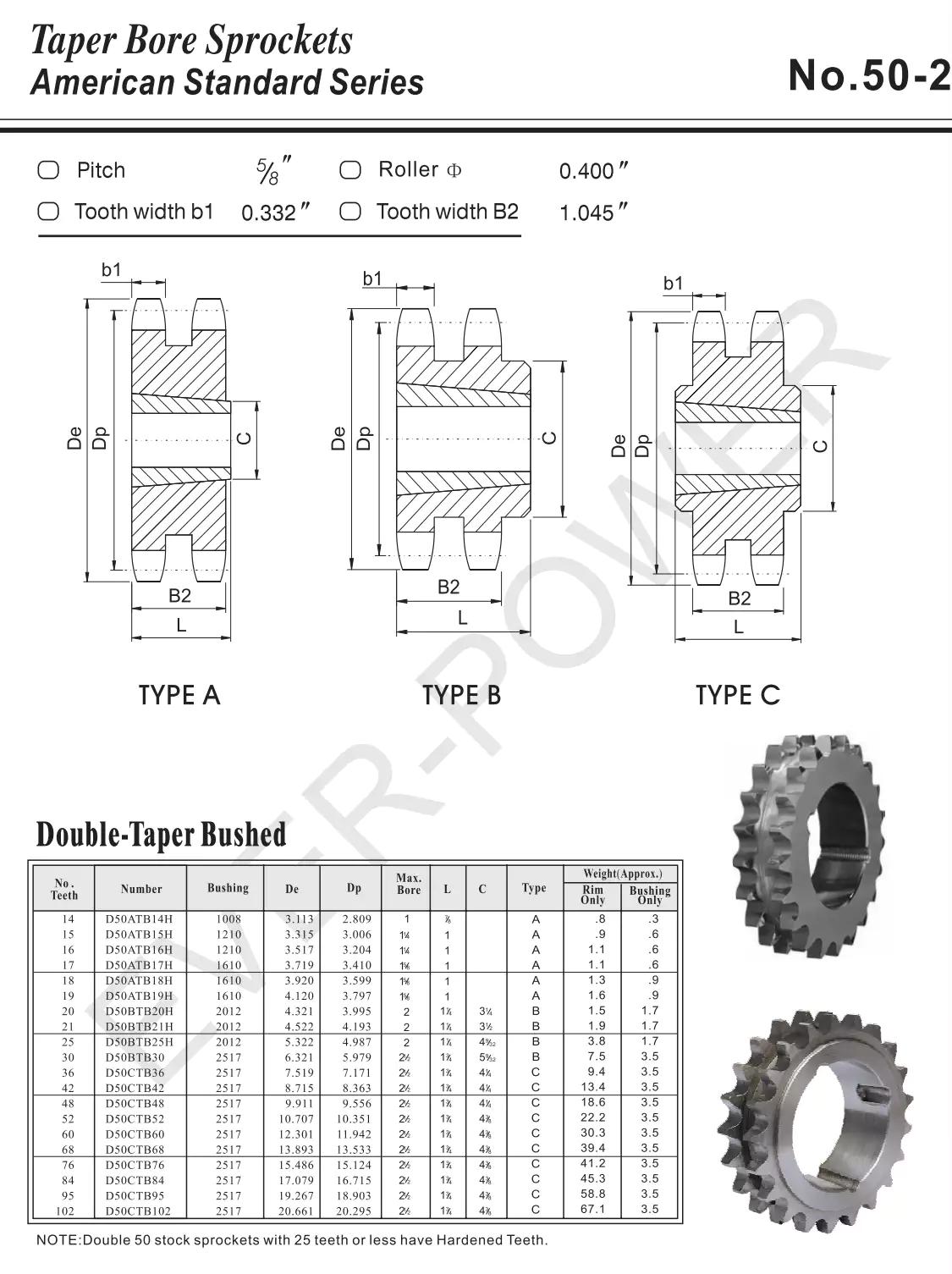

#50-2 5/8″ Taper Bore Sprocket

The #50-2 5/8″ Taper Bore Sprocket is designed for robust performance in various applications. Constructed from high-quality materials, it ensures durability and reliability. With a precise taper bore for easy installation, this sprocket is ideal for conveying systems and machinery that require efficient power transmission. Enhance your operations with this essential component.

#50-2 5/8" Taper Bore Sprocket Specifications

The #50-2 5/8" Taper Bore Sprocket serves as an essential element in power transmission systems. Its taper lock feature allows for easy installation and removal, making it user-friendly. This sprocket is designed to effectively transmit power between shafts, contributing to seamless operation across various machinery.

Characteristics and Functions

- Easy Installation: The taper lock design significantly streamlines the installation process, leading to time and effort savings.

- High Precision Positioning: The taper lock mechanism ensures precise alignment, thus minimizing the chances of misalignment.

- Wide Applicability: These sprockets find use in diverse sectors, including manufacturing, agriculture, and mining.

- Reliability: The sturdy connection guarantees dependable power transmission, even when subjected to heavy loads.

- Low Maintenance Cost: They require minimal maintenance, resulting in substantial cost savings for organizations.

A notable advantage of taper lock sprockets is their simple installation and removal process. The taper lock system enables quick and easy mounting and dismounting without needing specialized tools, which enhances efficiency during maintenance and replacement activities.

Installation and Removal Process

- Prepare Tools and Materials: Collect necessary tools including a torque wrench, hex keys, and an anti-seize compound to ensure smooth operation.

- Clean Shaft and Sprocket Surface: Thoroughly clean both the shaft and sprocket surfaces to eliminate any debris or contaminants that could interfere with proper installation.

- Place Taper Lock Bushing: Carefully insert the taper lock bushing into the sprocket bore, ensuring it aligns perfectly with the keyway located on the shaft.

- Install Sprocket: Slide the sprocket onto the shaft, making sure the teeth engage properly with the drive chain while aligning it accurately with other components.

- Tighten Locking Nut: Using a torque wrench, securely tighten the locking nut to ensure the sprocket is firmly attached and under the right tension.

Manufacturing Process

- Prepare Raw Materials: Select high-grade steel or suitable materials that are ideal for manufacturing and ensure quality.

- Cutting: Shape the selected raw material to establish the base structure of the sprocket.

- Forging or Casting: Employ forging or casting methods to create the sprocket, focusing on achieving desired strength and durability.

- Machining: Perform precise machining operations to create the teeth and other specific details necessary for functionality.

- Gear Cutting: Utilize specialized tools to accurately cut the gear teeth for effective power transmission.

- Heat Treatment: Apply heat treatment techniques to enhance hardness, strength, and wear resistance of the product.

- Surface Treatment: Coat or plate the sprocket to safeguard against corrosion while also improving its aesthetic appeal.

- Quality Inspection: Undertake thorough inspections to confirm that the sprocket meets all required standards and specifications.

Sprockets Supplier in Netherlands

RP Techniek BV is the sales representative for Ever-power Group, a prominent manufacturer of industrial components. We specialize in offering high-quality taper bore sprockets, including the #50-2 5/8" Taper Bore Sprocket, designed for optimal performance and lasting durability across various applications. Our extensive product line ensures that we are equipped to meet the unique needs of our clients, whether for standard or bespoke requirements. In addition to our conventional sprockets, we also provide non-standard customization services tailored to customer specifications. We encourage all clients to share their designs or samples with us for customized solutions that seamlessly fit their operational needs.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...