Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Specifications

- Type: Duplex Short Pitch Stainless Steel Roller Chain

- Model: 48ASS-2/240SS-2

- Pitch Size: 1/2 inch

- Roller Diameter: 0.306 inch

- Width Between Inner Plates: 0.312 inch

- Pin Diameter: 0.156 inch

- Pin Length: 0.843 inch

- Inner Plate Depth: 0.551 inch

- Plate Thickness: 0.06 inch

- Average Tensile Strength: 5,310 lbs

- Weight per Foot: 0.88 lbs

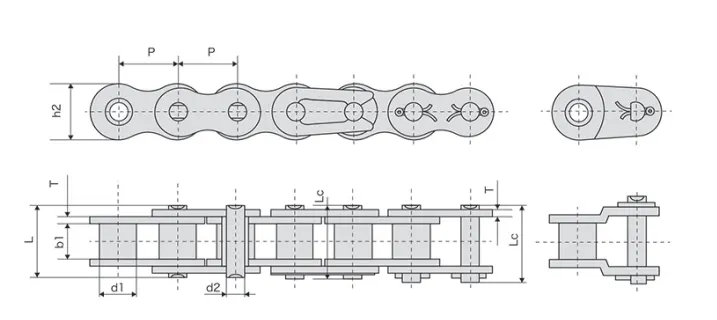

| simplex Stainless Steel Roller Chains& bushing chains | ||||||||||||

| DIN ISO | ANSI | pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mm | mm | mm | mm | kN | kN | kg/m | ||

| *04CSS-1 | *25SS | 6.35 | 3.3 | 3.18 | 2.31 | 7.9 | 8.4 | 6 | 0.8 | 2.1 | 2.76 | 0.15 |

| *06CSS-1 | *35SS | 9.525 | 5.08 | 4.77 | 3.58 | 12.4 | 13.17 | 9 | 1.3 | 4.74 | 6.48 | 0.33 |

| 085SS-1 | 41SS | 12.7 | 7.77 | 6.25 | 3.58 | 13.75 | 15 | 9.91 | 1.3 | 4 | 7.56 | 0.41 |

| 08ASS-1 | 40SS | 12.7 | 7.95 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 1.5 | 8.46 | 10.5 | 0.62 |

| 10ASS-1 | 50SS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.09 | 2.03 | 13.32 | 17.64 | 1.02 |

| 12ASS-1 | 60SS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 2.42 | 19.08 | 49.88 | 1.5 |

| 16ASS-1 | 80SS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 3.25 | 34.02 | 41.64 | 2.6 |

| 20ASS-1 | 100SS | 31.75 | 19.05 | 18.9 | 9.53 | 40.4 | 44.7 | 30 | 4 | 53.1 | 65.52 | 3.91 |

| 24ASS-1 | 120SS | 38.1 | 22.23 | 25.22 | 11.1 | 50.3 | 54.3 | 35.7 | 4.8 | 76.2 | 93.78 | 5.62 |

| 28ASS-1 | 140SS | 44.45 | 25.4 | 25.22 | 12.7 | 54.4 | 59 | 41 | 5.6 | 103.44 | 127.2 | 7.5 |

| 32ASS-1 | 160SS | 50.8 | 28.58 | 31.55 | 14.27 | 64.8 | 69.6 | 47.8 | 6.4 | 136.08 | 167.34 | 10.1 |

| 36ASS-1 | 180SS | 57.15 | 35.71 | 35.48 | 17.46 | 72.8 | 78.6 | 53.6 | 7.2 | 168.12 | 205.08 | 13.456 |

| 40ASS-1 | 200SS | 63.5 | 39.68 | 37.85 | 19.85 | 80.3 | 87.2 | 60 | 8 | 212.28 | 258.96 | 16.15 |

| 48ASS-1 | 240SS | 76.2 | 47.63 | 47.35 | 23.81 | 95.5 | 103 | 72.39 | 9.5 | 306.18 | 373.5 | 23.2 |

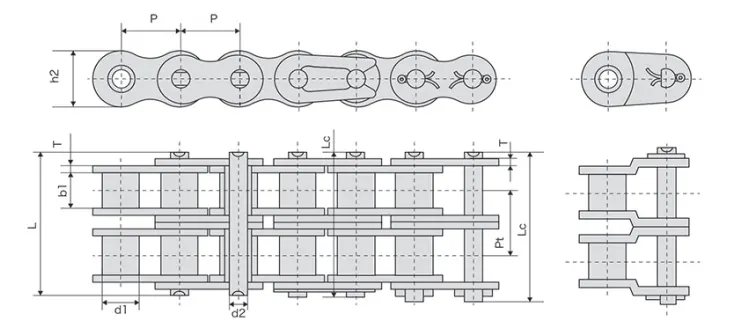

| Duplex Stainless Steel Roller Chains & bushing chains | |||||||||||||

| IDN ISO Chain No. | ANSI Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mmm | mm | mm | mm | mm | kN | kN | kg/m | ||

| *04CSS-2 | *25SS-2 | 6.35 | 3.3 | 3.18 | 2.31 | 14.5 | 15 | 6 | 0.8 | 6.4 | 4.2 | 5.16 | 0.28 |

| *06CSS-2 | *35SS-2 | 9.525 | 5.08 | 4.77 | 3.58 | 22.5 | 23.3 | 9 | 1.3 | 10.13 | 9.48 | 11.82 | 0.63 |

| 085SS-2 | 41SS-2 | 12.7 | 7.77 | 6.25 | 3.58 | 25.7 | 26.9 | 9.91 | 1.3 | 11.95 | 8 | 10.14 | 0.81 |

| 08ASS-2 | 40SS-2 | 12.7 | 7.95 | 7.85 | 3.96 | 31 | 32.2 | 12 | 1.5 | 14.38 | 16.92 | 21.54 | 1.12 |

| 10ASS-2 | 50SS-2 | 15.875 | 10.16 | 9.4 | 5.08 | 38.9 | 40.4 | 15.09 | 2.03 | 18.11 | 26.46 | 34.86 | 2 |

| 12ASS-2 | 60SS-2 | 19.05 | 11.91 | 12.57 | 5.94 | 48.8 | 50.5 | 18 | 2.42 | 22.78 | 38.16 | 49.26 | 2.92 |

| 16ASS-2 | 80SS-2 | 25.4 | 15.88 | 15.75 | 7.92 | 62.7 | 64.3 | 24 | 3.25 | 29.29 | 68.04 | 85.08 | 5.15 |

| 20ASS-2 | 100SS-2 | 31.75 | 19.05 | 18.9 | 9.53 | 76.4 | 80.5 | 30 | 4 | 35.76 | 106.2 | 131.64 | 7.8 |

| 24ASS-2 | 120SS-2 | 38.1 | 22.23 | 25.22 | 11.1 | 95.8 | 99.7 | 35.7 | 4.8 | 45.44 | 152.4 | 188.94 | 11.7 |

| 28ASS-2 | 140SS-2 | 44.45 | 25.4 | 25.22 | 12.7 | 103.3 | 107.9 | 41 | 5.6 | 48.87 | 206.88 | 256.5 | 15.14 |

| 32ASS-2 | 160SS-2 | 50.8 | 28.58 | 31.55 | 14.27 | 123.3 | 128.1 | 47.8 | 6.4 | 58.55 | 272.16 | 337.44 | 20.14 |

| 36ASS-2 | 180SS-2 | 57.15 | 35.71 | 35.48 | 17.46 | 138.6 | 144.4 | 53.6 | 7.2 | 65.84 | 336.3 | 417 | 29.22 |

| 40ASS-2 | 200SS-2 | 63.5 | 39.68 | 37.85 | 19.85 | 151.9 | 158.8 | 60 | 8 | 71.55 | 424.56 | 526.44 | 32.24 |

| 48ASS-2 | 240SS-2 | 76.2 | 47.63 | 47.35 | 23.81 | 183.4 | 190.8 | 72.39 | 9.5 | 87.83 | 612.36 | 753.18 | 45.23 |

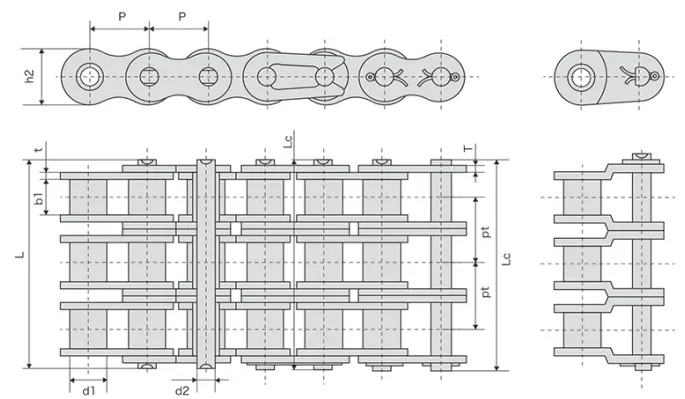

| Triplex Stainless Steel Roller Chains & bushing chains | |||||||||||||

| DIN ISO Chain No. | ANSI Chain No. | Pitch | Roller diameter | Width between inner plates | Pin diameter | Pin length | Inner plate depth | Plate thickness | Transverse pitch | Ultimate tensile strength | Average tensile strength | Weight per meter | |

| P | d1(max) | b1(min) | d2(max) | L(max) | Lc(max) | h2(max) | T(max) | Pt | Q(min) | Q0 | q | ||

| mm | mm | mm | mm | mmm | mm | mm | mm | mm | kN | kN | kg/m | ||

| *04CSS-3 | *25SS-3 | 6.35 | 3.3 | 3.18 | 2.31 | 21 | 21.5 | 6 | 0.8 | 6.4 | 6.3 | 7.56 | 0.44 |

| *06CSS-3 | *35SS-3 | 9.525 | 5.08 | 4.77 | 3.58 | 32.7 | 33.5 | 9 | 1.3 | 10.13 | 14.22 | 17.16 | 1.05 |

| 08ASS-3 | 40SS-3 | 12.7 | 7.95 | 7.85 | 3.96 | 45.4 | 46.6 | 12 | 1.5 | 14.38 | 25.38 | 30 | 1.9 |

| 10ASS-3 | 50SS-3 | 15.875 | 10.16 | 9.4 | 5.08 | 57 | 58.5 | 15.09 | 2.03 | 18.11 | 39.96 | 46.68 | 3.09 |

| 12ASS-3 | 60SS-3 | 19.05 | 11.91 | 12.57 | 5.94 | 71.5 | 73.3 | 18 | 2.42 | 22.78 | 57.24 | 66.66 | 4.54 |

| 16ASS-3 | 80SS-3 | 25.4 | 15.88 | 15.75 | 7.92 | 91.7 | 93.6 | 24 | 3.25 | 29.29 | 102.06 | 119.04 | 7.89 |

| 20ASS-3 | 100SS-3 | 31.75 | 19.05 | 18.9 | 9.53 | 112.2 | 116.3 | 30 | 4 | 35.76 | 159.3 | 185.76 | 11.77 |

| 24ASS-3 | 120SS-3 | 38.1 | 22.23 | 25.22 | 11.1 | 141.4 | 145.2 | 35.7 | 4.8 | 45.44 | 228.6 | 262.32 | 17.53 |

| 28ASS-3 | 140SS-3 | 44.45 | 25.4 | 25.22 | 12.7 | 152.2 | 156.8 | 41 | 5.6 | 48.87 | 342.72 | 355.98 | 22.2 |

| 32ASS-3 | 160SS-3 | 50.8 | 28.58 | 31.55 | 14.27 | 181.8 | 186.6 | 47.8 | 6.4 | 58.55 | 408.24 | 468.36 | 30.02 |

| 36ASS-3 | 180SS-3 | 57.15 | 35.71 | 35.48 | 17.46 | 204.4 | 210.2 | 53.6 | 7.2 | 65.84 | 504.42 | 590.16 | 38.22 |

| 40ASS-3 | 200SS-3 | 63.5 | 39.68 | 37.85 | 19.85 | 223.5 | 230.4 | 60 | 8 | 71.55 | 636.84 | 730.68 | 49.03 |

| 48ASS-3 | 240SS-3 | 76.2 | 47.63 | 47.35 | 23.81 | 271.3 | 278.6 | 72.39 | 9.5 | 87.83 | 918.54 | 1053.9 | 71.6 |

Introduction

The 48ASS-2/240SS-2 Duplex Short Pitch Stainless Steel Roller Chain is a high-quality roller chain designed for heavy-duty industrial applications. It is made of stainless steel, which makes it highly resistant to corrosion, wear, and abrasion. This roller chain is ideal for use in harsh environments where traditional roller chains would quickly deteriorate.

Design and Construction

The 48ASS-2/240SS-2 Duplex Short Pitch Stainless Steel Roller Chain features a duplex design, which means it has two parallel chains that are linked together by pins. This design enhances the strength and durability of the roller chain. The pitch size of the chain is short, which means the distance between each pin is smaller than that of a standard roller chain. The rollers are also made of stainless steel, and they are precision ground for smooth operation. The sprockets for this roller chain are also made of stainless steel, ensuring a long service life.

Applications

The 48ASS-2/240SS-2 Duplex Short Pitch Stainless Steel Roller Chain is commonly used in applications that require high strength and corrosion resistance. It is ideal for use in the food and beverage industry, as well as in chemical plants and other harsh environments. This roller chain is suitable for conveying heavy loads and is often used in conveyor systems, processing equipment, and packaging machinery.

Maintenance

The 48ASS-2/240SS-2 Duplex Short Pitch Stainless Steel Roller Chain requires regular maintenance to ensure optimal performance and a long service life. It is recommended to lubricate the chain regularly with a high-quality lubricant to reduce friction and wear. It is also important to inspect the chain periodically for signs of wear, such as elongation or damaged rollers. Any worn or damaged components should be replaced promptly to prevent further damage to the chain and the equipment it is used on.

Conclusion

The 48ASS-2/240SS-2 Duplex Short Pitch Stainless Steel Roller Chain is a reliable and durable roller chain that is ideal for use in harsh environments. Its stainless steel construction ensures high resistance to corrosion, wear, and abrasion, making it suitable for a wide range of applications. Regular maintenance is essential to keep this roller chain in optimal condition and to prolong its service life.

Choose Our Stainless Steel Roller Chains

RP Techniek BV is the authorized sales agent in the Netherlands for Ever-power Group. We take pride in offering high-quality products and excellent service to our customers. One of our standout products is the 48ASS-2/240SS-2 Duplex Short Pitch Stainless Steel Roller Chain.

Our stainless steel roller chains are known for their durability and reliability. They are designed to withstand harsh conditions and heavy loads, making them ideal for various industrial applications. With our advanced manufacturing capabilities, we ensure that each chain meets the highest quality standards.

At RP Techniek BV, we offer a wide range of other stainless steel roller chains as well. Whether you need simple or complex chain designs, we have options to suit your specific requirements. Our diverse product line ensures that you can find the perfect chain for your needs.

We are committed to providing our customers with top-notch products and exceptional service. With our extensive industry experience, we understand the needs of our clients and strive to exceed their expectations. You can trust us to deliver reliable solutions that meet your demands.

Take a look at the image below to see the quality and craftsmanship of our stainless steel roller chains:

Sprockets for Sale

For the 48ASS-2/240SS-2 Duplex Short Pitch Stainless Steel Roller Chain, we have a variety of suitable sprockets available for purchase. Our sprockets are made from high-quality materials and are designed to provide reliable and efficient performance.

At our company, we offer a wide range of different types of sprockets, including single, double, and triple strand sprockets, as well as custom sprockets made to meet specific customer requirements. Our sprockets are available in various materials, such as steel, stainless steel, and plastic.

No matter what your application or industry, we have the right sprocket for you. Our experienced team will work with you to determine the best sprocket for your needs and ensure that you receive a product that meets your expectations.

Take a look at our selection of sprockets and contact us today to learn more about how we can help you with your sprocket needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...