In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

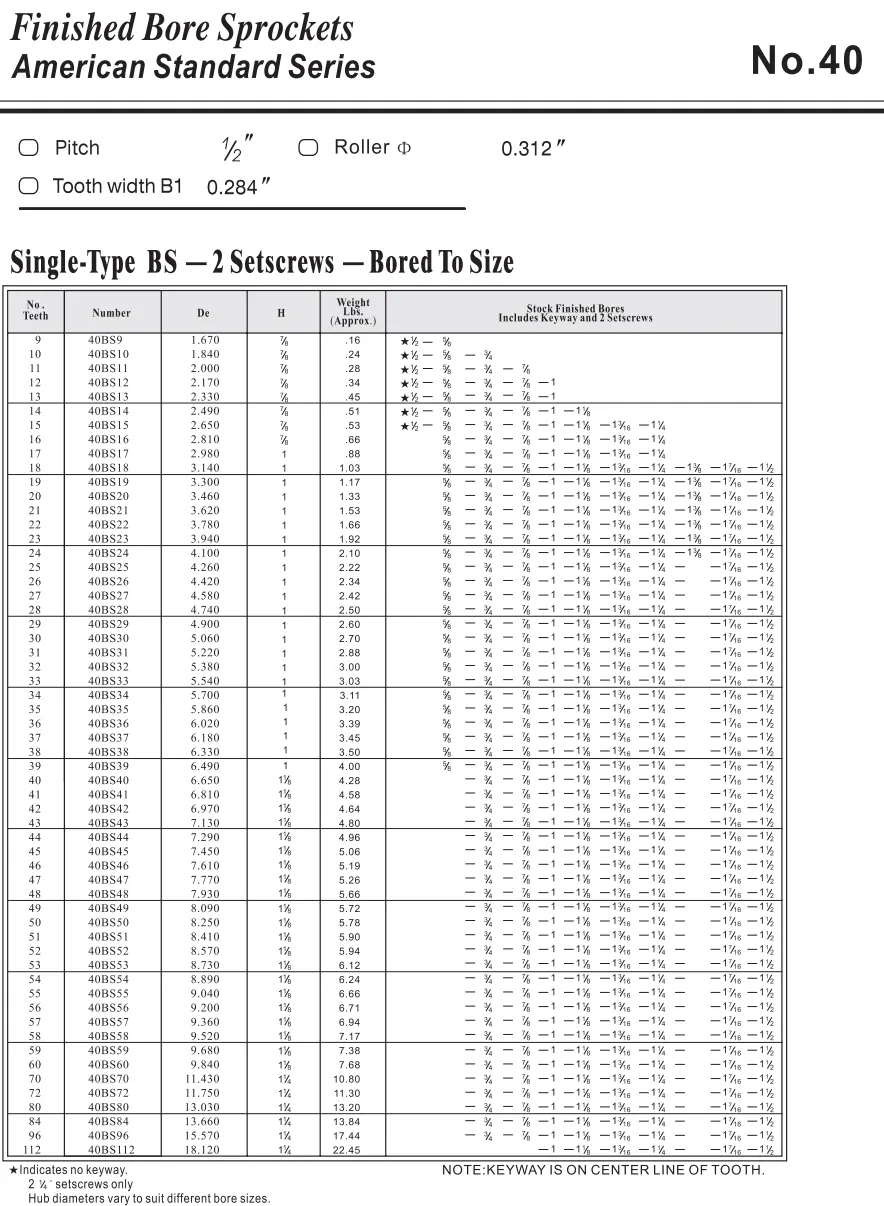

40BS* Finished Bore Sprocket

The 40BS* Finished Bore Sprocket is engineered for precision and durability, making it ideal for various applications in machinery and conveyor systems. Crafted from high-quality materials, it ensures optimal performance and longevity. Its finished bore design allows for easy installation, enhancing efficiency in power transmission and reducing downtime.

Specifications of 40BS* Finished Bore Sprocket

A finished bore sprocket is specifically designed with a pre-bored hole that allows it to fit securely onto a shaft without the need for any additional machining processes. These sprockets play a crucial role in power transmission systems, facilitating the efficient transfer of motion between two shafts, which is essential for the operation of various machinery and equipment.

Materials and Manufacturing Process

The finished bore sprockets are manufactured using high-quality materials and undergo a comprehensive series of manufacturing steps to ensure they possess the durability and performance needed for demanding applications:

- Materials: High carbon steel, alloy steel, or stainless steel are commonly used for their strength and reliability.

- Manufacturing Process: The process includes material selection, cutting, stamping, forging, machining (turning, milling, drilling), heat treatment (including quenching, tempering, and surface hardening), surface treatment (for rust prevention), and thorough quality inspection.

Maintenance and Care of Sprockets

Proper maintenance and care are essential for extending the lifespan and ensuring the efficient functionality of sprockets. To achieve this, the following best practices should be implemented consistently:

- Conduct daily inspections to check for any signs of wear or damage that may affect performance.

- Keep the sprockets clean by removing dirt, debris, and contaminants that can cause issues.

- Apply regular lubrication to reduce friction and prevent corrosion, which can lead to failures.

- Make necessary adjustments and calibrations to ensure that appropriate tension and alignment are maintained.

Common issues that can arise with sprockets include tooth skipping, breakage, wear, excessive noise, and chain slippage. Here are solutions for addressing each of these problems:

- Tooth skipping: Ensure that chain tension is adequate, check alignment, and replace any worn components as needed.

- Breakage: Inspect for cracks or damage and replace the sprocket with a new one if necessary to avoid further complications.

- Wear: Regular monitoring of wear is crucial; replace worn sprockets promptly to prevent chain slippage.

- Excessive noise: Proper lubrication is key; also, check for any misalignment that could contribute to noise issues.

- Chain slippage: Adjust the tension and alignment as needed, replacing worn components to ensure smooth operation.

Other Types of Sprockets and Chains

In addition to the 40BS* Finished Bore Sprocket, we provide a wide variety of other sprockets, including taper lock sprockets, QD sprockets, idler sprockets, along with various types and models of chains to suit different applications.

Sprockets Supplier in Netherlands

RP Techniek BV is the sales agent for Ever-power Group in the Netherlands, offering a diverse range of high-quality sprockets to meet various industrial requirements. Among our featured products is the 40BS* Finished Bore Sprocket, engineered for optimal performance and reliable durability across multiple applications. Our sprockets are manufactured with precision, ensuring they integrate seamlessly with compatible chains to enhance the efficiency of your machinery.

Beyond our standard offerings, we specialize in custom solutions, allowing us to create non-standard sprockets tailored to meet your specific needs. We encourage customers to reach out with their designs or samples for custom fabrication. Our dedicated team is committed to delivering the best products and services to satisfy your operational requirements.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...