In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications of 400CSS**/W3635SS Stainless Steel Hollow Pin Chain:

- Material: Stainless Steel

- Chain Type: Hollow Pin Chain

- Model Number: 400CSS**/W3635SS

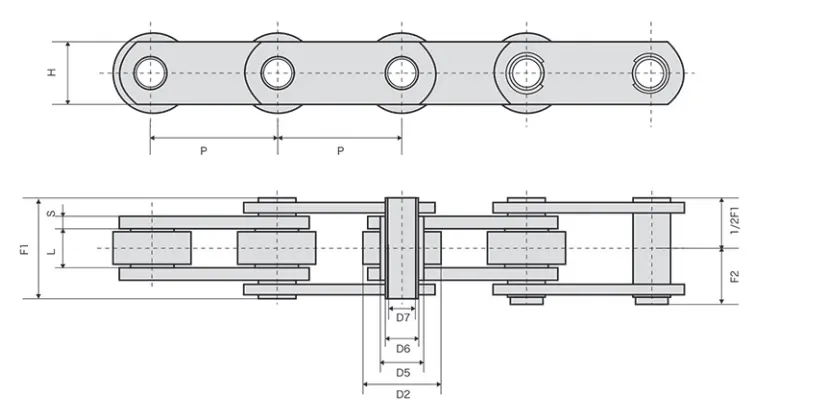

| Chain No. |

P(mm) | L(mm) | D2(mm) | D5(mm) | D6(mm) | D7(mm) | H(mm) | S(mm) | F1(mm) | F2(mm) | Breaking(Load N) | Weight(kg/m) |

| 250RSS | 50 | 11,5 | 25 | 11 | 9 | 6.2 | 20 | 2.5 | 25 | 14 | 38 | 1.8 |

| 250SS | 50 | 11.5 | 25 | 11 | 9 | 6.2 | 20 | 2.5 | 25 | 14 | 25 | 1.8 |

| 400CSS* | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 3 | 31 | 17 | 35 | 3 |

| W3635SS | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 3 | 31 | 17 | 35 | 3 |

| 500CRPSS | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 18.5 | 65 | 3.6 |

| 500CSS* | 50 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 20 | 40 | 3.6 |

| 501CSS | 75 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 20 | 40 | 3.1 |

| 502CSS | 100 | 15 | 31 | 17 | 14 | 10,2 | 25 | 4 | 35 | 20 | 40 | 2.6 |

| 503CSS | 125 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 18.5 | 40 | 2.4 |

| 503CSS | 125 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 20 | 40 | 2.4 |

| 504CSS | 150 | 15 | 31 | 17 | 14 | 10.2 | 25 | 4 | 35 | 18.5 | 40 | 2.3 |

| 701CSS | 75 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 5.4 |

| 703CSS | 100 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 4.4 |

| 703CRSS | 100 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 75 | 0.4 |

| 704CSS | 125 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 4.2 |

| 704CRSS | 125 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 75 | 4.2 |

| 705CSS | 150 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 60 | 4 |

| 705CRSS | 150 | 22 | 40 | 23 | 18 | 12.2 | 35 | 4 | 45 | 23.5 | 75 | 4 |

400CSS**/W3635SS Stainless Steel Hollow Pin Chain

Title 1: Introduction to 400CSS**/W3635SS Stainless Steel Hollow Pin Chain

Discover the exceptional performance and durability of the 400CSS**/W3635SS Stainless Steel Hollow Pin Chain. This high-quality chain is designed to meet the demanding requirements of various industries, providing reliable and efficient operation in even the harshest environments.

Title 2: Superior Strength and Corrosion Resistance

With its stainless steel construction, the 400CSS**/W3635SS Hollow Pin Chain offers unparalleled strength and exceptional resistance to corrosion. This ensures optimal performance and longevity, making it ideal for applications where durability is crucial.

Sub-title: Advanced Stainless Steel Alloy

The 400CSS**/W3635SS Chain is crafted from a specialized stainless steel alloy, specifically engineered to provide superior strength and corrosion resistance. This unique alloy composition enhances the chain's durability, allowing it to withstand heavy loads and harsh environmental conditions.

Sub-title: Surface Coating Technology

Utilizing cutting-edge surface coating technology, the 400CSS**/W3635SS Chain offers added protection against corrosion and wear. The innovative coating enhances the chain's resistance to chemicals, moisture, and extreme temperatures, further extending its lifespan and ensuring reliable performance.

Title 3: Versatile Applications

The versatility of the 400CSS**/W3635SS Stainless Steel Hollow Pin Chain makes it suitable for a wide range of applications. From food processing and pharmaceutical industries to high-temperature environments and heavy-duty machinery, this chain excels in various demanding settings.

Sub-title: Food Processing Industry

Compliant with stringent hygiene standards, the 400CSS**/W3635SS Chain is an excellent choice for the food processing industry. Its stainless steel construction and corrosion resistance ensure safe operation and prevent contamination, maintaining the integrity of the production process.

Sub-title: Pharmaceutical Industry

In the pharmaceutical industry, where cleanliness is of utmost importance, the 400CSS**/W3635SS Chain meets the strict requirements. It offers reliable performance, high resistance to chemicals and corrosion, and easy cleaning, making it an ideal choice for critical pharmaceutical applications.

Title 4: Precision Engineering and Smooth Operation

Engineered with precision, the 400CSS**/W3635SS Stainless Steel Hollow Pin Chain delivers smooth and efficient operation. Its tight tolerances and accurate assembly ensure minimal friction and optimal power transmission, reducing wear and tear and maximizing overall performance.

Sub-title: Hollow Pin Design

The unique hollow pin design of the 400CSS**/W3635SS Chain allows for easy installation and removal, simplifying maintenance procedures. This feature also enhances flexibility by enabling accessories, such as attachments and guide rails, to be easily incorporated into the chain.

Sub-title: Low Noise and Vibration

Thanks to its precise engineering and high-quality materials, the 400CSS**/W3635SS Chain operates with minimal noise and vibration. This reduces operator fatigue and ensures a quieter work environment, enhancing overall productivity and user comfort.

Title 5: Customizable Options

To meet specific application requirements, the 400CSS**/W3635SS Stainless Steel Hollow Pin Chain offers customizable options. From different pitch sizes and attachment configurations to specialized coatings and finishes, this chain can be tailored to suit individual needs.

Sub-title: Attachment Options

The 400CSS**/W3635SS Chain can be equipped with a variety of attachments, allowing for easy integration into complex machinery and conveyor systems. Whether it's for product handling, sorting, or lifting, the chain can be customized to accommodate specific attachment requirements.

Sub-title: Coating and Finish Options

With a range of coating and finish options available, the 400CSS**/W3635SS Chain can be further enhanced to meet specific environmental conditions. From specialized anti-corrosion coatings to low-friction finishes, these options ensure optimal performance and longevity in diverse operating environments.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV is the official sales agent of Ever-power Group in the Netherlands. We take pride in providing high-quality stainless steel roller chains to our customers, including the 400CSS**/W3635SS Stainless Steel Hollow Pin Chain.

Our stainless steel roller chains are designed to deliver exceptional performance in extreme environments. They are highly resistant to corrosion, wear, and heat, making them ideal for use in industries such as food processing, chemical manufacturing, and marine applications.

At RP Techniek BV, we are committed to providing excellent customer service, timely delivery, and competitive pricing. Our team of experts ensures that our products meet the highest standards of quality and reliability.

In addition to the 400CSS**/W3635SS Stainless Steel Hollow Pin Chain, we offer a wide range of other stainless steel roller chains, including standard chains, conveyor chains, and specialty chains. We have the expertise and manufacturing capabilities to custom design chains to meet your specific requirements.

Choose RP Techniek BV for all your stainless steel roller chain needs and experience the difference in quality and service.

Sprockets for Sale

When it comes to the 400CSS**/W3635SS stainless steel hollow pin chain, finding the right sprocket is crucial for ensuring optimal performance. At our company, we offer a wide range of sprockets to fit every need. Our selection includes various sizes, tooth counts, and materials to ensure that our customers can find the perfect match for their chain.

Whether you are looking for a simple steel sprocket or a more specialized option such as a hard-anodized aluminum sprocket, we have you covered. We understand that every application is unique, and we strive to provide our customers with the best options to suit their needs.

Our sprockets are designed with durability and longevity in mind, ensuring that they can withstand the demands of even the most challenging environments. With our high-quality products and commitment to customer satisfaction, we are confident that you will find the perfect sprocket for your application at our company.

Check out our selection online or give us a call to discuss your specific needs. We are always happy to help you find the perfect sprocket for your application.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...