In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

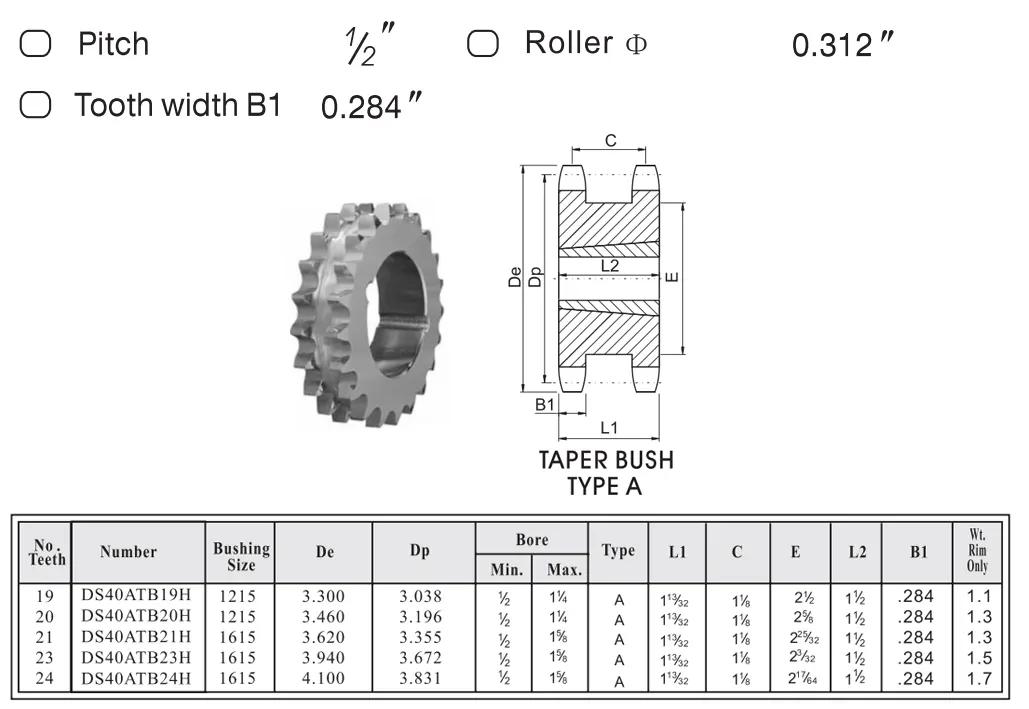

40 Taper Bushed Type Double Single Sprocket

The 40 Taper Bushed Type Double Single Sprocket is engineered for durability and efficiency in power transmission. Designed to accommodate taper bushings, it provides easy installation and maintenance. This versatile sprocket is ideal for various industrial applications, ensuring reliable performance in challenging environments while maintaining optimal chain alignment.

Specifications of 40 Taper Bushed Type Double Single Sprocket

Design Features of 40 Taper Bushed Type Double Single Sprocket

The 40 Taper Bushed Type Double Single Sprocket is specially designed to support two single-row chains, which facilitates simultaneous driving capabilities. This innovative dual-chain configuration significantly enhances the versatility of power transmission, making it suitable for a wide array of applications. The tapered bush used in the design ensures a secure fit and simplifies maintenance tasks, while also optimizing torque transfer efficiency. This clever design approach not only maximizes operational effectiveness but also minimizes wear and tear, leading to an extended lifespan and improved performance in various mechanical systems.

Surface Treatment of 40 Taper Bushed Type Double Single Sprocket

The surface treatment procedure for the 40 Taper Bushed Type Double Single Sprocket consists of several essential steps aimed at enhancing its durability and resistance to wear. Initially, the surface undergoes thorough cleaning to eliminate any potential contaminants. Subsequently, a high-performance coating is applied to significantly boost the sprocket's hardness. This is followed by a heat treatment phase designed to optimize the material's inherent properties. Finally, a rigorous quality inspection is performed to ensure that each sprocket meets strict durability criteria. Collectively, these surface treatments extend the life of the sprocket, making it well-suited for demanding applications.

Application Areas of 40 Taper Bushed Type Double Single Sprocket

The 40 Taper Bushed Type Double Single Sprocket is tailored to meet various challenges in mechanical power transmission. Its applications are vital across several industries:

- Automotive: Leveraged in conveyor systems for the efficient movement of parts and components.

- Agriculture: Powers essential equipment like harvesters and tractors to enhance productivity.

- Manufacturing: Plays a crucial role in assembly lines, ensuring reliable operation and output.

- Mining: Facilitates the transportation of heavy machinery and materials within mines.

- Textile: Implements in looms and other fabric machinery, contributing to the textile production process.

Optimized Sprocket Spacing Design

The 40 Taper Bushed Type Double Single Sprocket incorporates a meticulously engineered design focused on achieving optimal sprocket spacing. This careful spacing is crucial as it ensures that the chain remains under proper tension and is aligned correctly, thus effectively minimizing any gaps while preventing mechanical interference. By adhering to precise measurements, the sprocket design significantly enhances overall performance by reducing wear and tear on both the chain and sprocket components. This ultimately results in greater longevity and reliability, allowing for smoother operations that maximize efficiency and minimize noise during movement.

Double Single Sprockets Supplier

RP Techniek BV is the Dutch sales agent for Ever-power Group and ranks among the top ten sprocket suppliers in the Netherlands. Our comprehensive product range features the 40 Taper Bushed Type Double Single Sprocket, revered for its durability and efficiency across various industrial applications. Designed to accommodate a broad spectrum of chain sizes, these sprockets guarantee optimal performance and longevity.

At RP Techniek BV, we are dedicated to providing exceptional customer service, offering expert support and guidance to assist you in selecting the right products for your specific needs. Our unwavering commitment to quality and reliability positions us as your trusted partner in the sprocket supply industry.

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...