In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

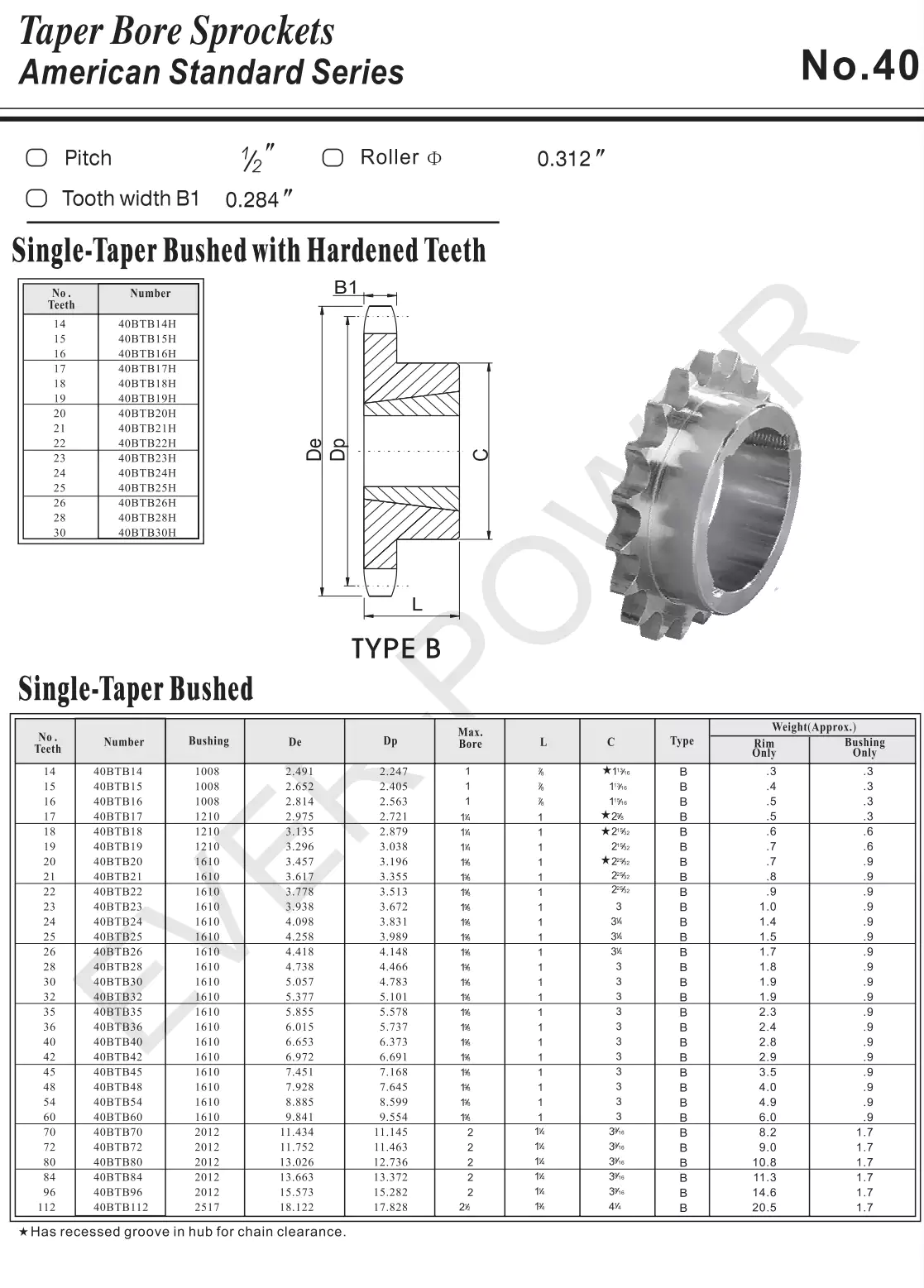

#40 1/2″ Taper Bore Sprocket

The #40 1/2″ Taper Bore Sprocket is designed for high-performance applications, featuring a robust construction that ensures durability and reliability. Its tapered bore allows for easy installation on various shaft sizes, making it versatile for different machinery. Ideal for power transmission, this sprocket enhances efficiency and reduces wear over time.

#40 1/2" Taper Bore Sprocket Specifications

#40 1/2" Taper Bore Sprocket represents a specialized component utilized in power transmission systems. It features a unique taper bore design that facilitates its secure attachment to a shaft through a taper lock bushing. This type of sprocket is favored across various industrial environments due to its reliability and high precision.

Taper Lock Sprocket Features and Functions

- Easy to Install: The design of taper lock sprockets allows for a straightforward installation and removal process, primarily due to the taper lock bushing that simplifies adjustments.

- High Precision Positioning: With the use of a taper lock bushing, the sprocket achieves precise positioning on the shaft, ensuring effective power transmission.

- Wide Applicability: These sprockets are versatile and can be employed in a variety of industrial applications, making them a popular choice among engineers.

- Reliability: Taper lock sprockets are known for their reliability, capable of handling substantial loads and performing well under demanding working conditions.

- Low Maintenance Cost: The straightforward design, along with the ease of installation and removal, contributes to reduced maintenance costs over time.

The straightforward process of installation and removal is particularly noteworthy, as it significantly saves time and labor during maintenance tasks and repairs. Taper lock sprockets are commonly found in conveyor systems, agricultural machinery, and a range of industrial equipment, proving their versatility and reliability.

Installation and Removal Process of Taper Lock Sprocket

The installation and removal of a taper lock sprocket can be efficiently completed by following these steps:

- Prepare Tools and Materials: Assemble all necessary tools and materials, including a torque wrench, taper lock bushing, and the sprocket itself, to ensure a smooth installation process.

- Clean Shaft and Sprocket Surface: Thoroughly clean the surfaces of both the shaft and the sprocket to prevent any dirt or debris from interfering with the installation.

- Place Taper Lock Bushing: Carefully position the taper lock bushing onto the shaft and secure it with the appropriate set screws to ensure a firm attachment.

- Install Sprocket: Slide the sprocket onto the taper lock bushing, making sure to align it correctly with the shaft for optimal performance.

- Tighten Locking Nut: Use a torque wrench to properly tighten the locking nut according to the torque specifications provided by the manufacturer.

Following the manufacturer's guidelines and adhering to torque specifications during both installation and removal is essential for maintaining the overall safety and reliability of the system.

Sprockets Supplier in the Netherlands

RP Techniek BV is the official sales agent for Ever-power Group in the Netherlands, providing a comprehensive range of high-quality sprockets and related products. Among our key offerings is the #40 1/2" Taper Bore Sprocket, engineered to ensure durability and optimal performance in various industrial applications. Our sprockets are crafted from superior materials, guaranteeing longevity and reliability for heavy-duty usage.

In addition to our standard product line, we specialize in creating custom solutions tailored to meet the unique requirements of our clients. We encourage customers to present their designs and samples for non-standard customization. Our dedicated team is equipped to assist you in developing the perfect sprocket to fulfill your specific needs.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...