Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

Types and Sizes of 35 Weld on Sprockets and Hubs

| No.Teeth | 35 |

| 3/8" Pitch | |

| 15 | 35V15 |

| 16 | 35V16 |

| 17 | 35V17 |

| 18 | 35V18 |

| 19 | 35V19 |

| 20 | 35V20 |

| 21 | 35V21 |

| 22 | 35W22 |

| 23 | 35W23 |

| 24 | 35W24 |

| 25 | 35W25 |

| 26 | 35W26 |

| 27 | 35W27 |

| 28 | 35W28 |

| 29 | 35W29 |

| 30 | 35W30 |

| 31 | 35W31 |

| 32 | 35W32 |

| 33 | 35W33 |

| 34 | 35W34 |

| 35 | 35W35 |

| 36 | 35W36 |

| 37 | 35W37 |

| 38 | 35W38 |

| 39 | 35W39 |

| 40 | 35W40 |

| 42 | 35W42 |

| 43 | 35W43 |

| 44 | 35W44 |

| 45 | 35W45 |

| 48 | 35W48 |

| 50 | 35W50 |

| 54 | 35W54 |

| 60 | 35W60 |

| 70 | 35W70 |

| 72 | 35W72 |

| 80 | 35W80 |

| 84 | 35W84 |

| 96 | 35W96 |

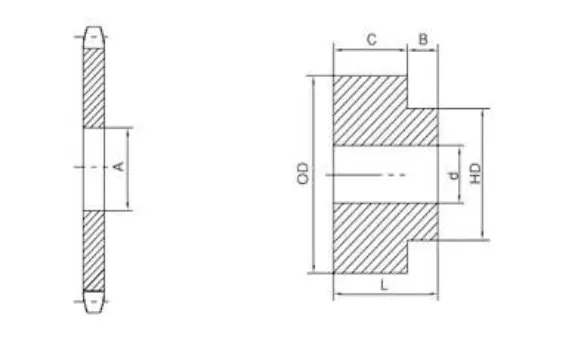

| Hub No. | Chain No. | d Min. |

d Max. |

OD | HD | L | B | C | App.WL. (Lbs.) | A |

| V | 35-60 | 0.5 | 0.875 | 1.438 | 1.125 | 1.188 | 0.438 | 0.75 | 0.32 | 1-1/8 |

| W | 35-80 | 0.5 | 1.25 | 1.813 | 1.625 | 1.438 | 0.438 | 1 | 0.64 | 1-5/8 |

| X | 40-100 | 0.5 | 1.5 | 2.5 | 2 | 1.438 | 0.438 | 1 | 1.42 | 2 |

| XX | 40-100 | 1 | 1.625 | 3 | 2 | 1.5 | 0.438 | 1.063 | 2.2 | 2 |

| Y | 100 | 1 | 2 | 3.75 | 2.75 | 1.875 | 0.688 | 1.188 | 3.92 | 2-3/4 |

Applications of 35 Weld on Sprockets and Hubs

The 35 Weld on Sprockets and Hubs are ideal for industries such as manufacturing, agriculture, and automotive. They are commonly used in conveyor systems, agricultural machinery, and various machinery where reliable power transmission is essential. These sprockets provide durability and ease of installation, making them suitable for projects requiring robust performance and long-lasting service. Assess your equipment needs to determine compatibility.

Installation of 35 Weld on Sprockets and Hubs

To install the 35 Weld on Sprockets and Hubs, follow these steps:

- Ensure the surfaces to be welded are clean and free from rust or debris.

- Align the sprocket or hub with the shaft, ensuring it is in the correct position.

- Use clamps to secure the sprocket or hub in place during welding.

- Apply the weld evenly around the joint, maintaining a consistent heat level.

- Allow the weld to cool before removing clamps and inspecting for any defects.

How to Choose the Right Weld on Sprockets and Hubs

Choosing the right weld on sprockets and hubs involves several key steps:

- Determine the Application: Consider the specific machinery and requirements in which the sprockets and hubs will be used.

- Check Size Compatibility: Ensure the dimensions match the existing components for a proper fit.

- Material Selection: Select materials that withstand the operating conditions, such as load and environmental factors.

- Review Tooth Count: The number of teeth affects speed and torque; choose accordingly for optimal performance.

Weld on Sprockets and Hubs for Sale in Netherlands

RP Techniek BV is the authorized sales agent for Ever-power Group in the Netherlands, and we are one of the top sprocket suppliers in the country. We specialize in providing high-quality welded sprockets and hubs, designed to meet the diverse needs of our customers. Our product range includes 35 different types of weld on sprockets and hubs, ensuring that you can find the perfect solution for your specific application.

At RP Techniek BV, we pride ourselves on our exceptional service. Our experienced team is dedicated to helping you choose the right products, providing prompt delivery, and offering expert advice to ensure your satisfaction. We are committed to delivering reliable and durable solutions to enhance your operations.

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...