In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

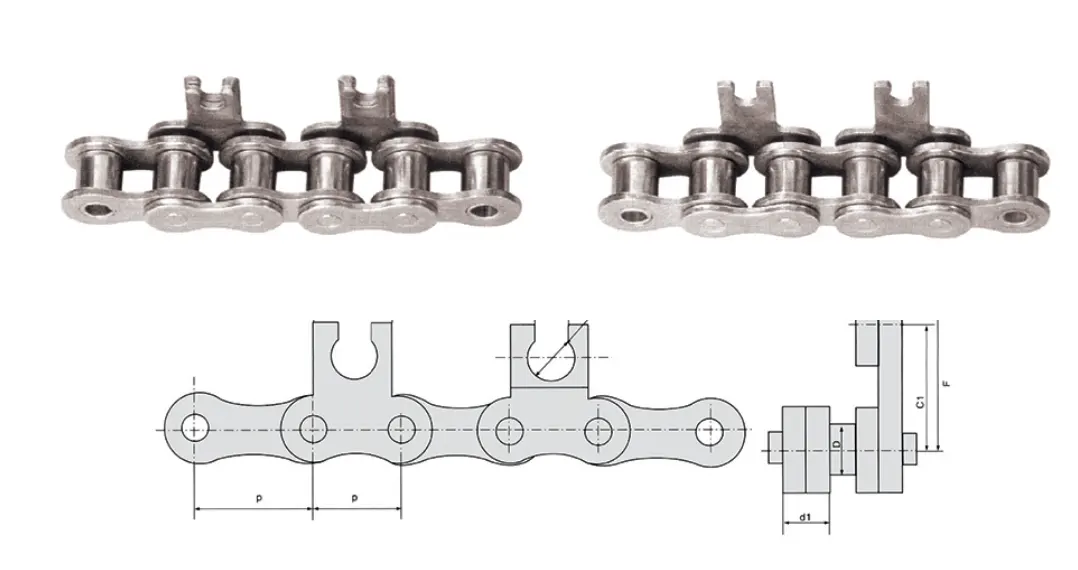

16ASS Stainless Steel Short Pitch Conveyor Chains for Popsicle Ice Machine

The 16ASS Stainless Steel Short Pitch Conveyor Chains are specifically crafted for utilization in Popsicle Ice Machines. Constructed from premium stainless steel, these chains are built to last and resist corrosion. Their short pitch design facilitates efficient and dependable movement during the popsicle ice manufacturing process.

Dimensions of 16ASS Stainless Steel Short Pitch Conveyor Chains for Popsicle Ice Machine

The 16ASS Stainless Steel Short Pitch Conveyor Chains for Popsicle Ice Machines offer a dependable and effective solution for transporting popsicle ice trays. Their resistance to corrosion, robust strength, and ease of maintenance contribute to smooth and consistent production in various ice cream and frozen dessert manufacturing environments. Investing in these chains will enhance the efficiency and reliability of your Popsicle Ice Machine.

The following are the specifications for the chain:

| Chain No. | Pitch | Width between inner plates |

||||||

| P mm |

bl min mm |

D max mm |

F mm |

C1 mm |

d mm |

S mm |

G mm |

|

| 16ASS | 25.4 | 15.75 | 15.88 | 40 | 32 | 8 | 6.6 | 18 |

Features of 16ASS Stainless Steel Popsicle Ice Machine Chain

1. Corrosion Resistance: The stainless steel material used in these chains prevents rust and deterioration, promoting a longer operational life.

2. Short Pitch Design: This design enables smooth and accurate movement of popsicle ice trays, ensuring steady production.

3. High Strength: Engineered to endure heavy loads, these chains deliver consistent performance even in challenging environments.

4. Easy Maintenance: The chains are designed for straightforward cleaning and upkeep, minimizing downtime and enhancing productivity.

5. Customizable Length: These chains can be tailored to fit the specific needs of various Popsicle Ice Machines.

Stainless Steel Popsicle Ice Machine Chain Applications

The 16ASS Stainless Steel Short Pitch Conveyor Chains are well-suited for a variety of Popsicle Ice Machines, including:

- Commercial popsicle manufacturing facilities

- Ice cream shops

- Frozen dessert production plants

- Catering establishments

Installation

1. Ensure the Popsicle Ice Machine is powered off and disconnected from any electrical source prior to installation.

2. Remove any existing chains from the machine, if necessary.

3. Align the ends of the 16ASS Stainless Steel Short Pitch Conveyor Chains with the sprockets or gears in the machine.

4. Insert the chain pins into the corresponding sprocket or gear holes.

5. Utilize a chain tensioner if needed to maintain proper chain tension.

6. Verify the alignment of the chains and make adjustments as required.

7. After the chains are correctly installed, reconnect the power source and switch on the Popsicle Ice Machine.

Maintenance

To maintain optimal performance and extend the lifespan of the 16ASS Stainless Steel Short Pitch Conveyor Chains, regular maintenance is advised:

1. Frequently inspect the chains for any signs of wear or damage.

2. Clean the chains with a mild detergent and water solution to eliminate debris and buildup.

3. Apply a suitable chain lubricant to decrease friction and prolong their longevity.

4. Immediately replace any worn or damaged chains to prevent interruptions in production.

5. Adhere to the manufacturer's guidelines regarding maintenance schedules and procedures.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV serves as the official sales representative for Ever-power Group in the Netherlands. We take pride in supplying top-quality stainless steel roller chains to our clients. Our 16ASS Stainless Steel Short Pitch Conveyor Chains for Popsicle Ice Machine exemplify the unique selling points that differentiate us from competitors.

Our stainless steel roller chains are crafted from high-grade materials that ensure durability and longevity. We emphasize quality control at every production stage to ensure our products comply with the highest standards. Our expert team conducts thorough testing on each product before it is released to the market.

We also prioritize customer satisfaction and provide exemplary customer service. Our team is always available to assist and offer solutions to any inquiries or concerns our clients may have. We believe that the success of our business is rooted in our customers' satisfaction.

In addition to our 16ASS Stainless Steel Short Pitch Conveyor Chains for Popsicle Ice Machine, we provide an extensive range of stainless steel roller chains tailored for various applications. Our products are adaptable and can be customized to meet specific requirements.

At RP Techniek BV, we take pride in our production capabilities. Our cutting-edge facilities and advanced technology enable us to manufacture high-quality products efficiently. We assure that our stainless steel roller chains are of the utmost quality, and we stand behind every product we offer.

Sprockets for Sale

When selecting sprockets for the 16ASS Stainless Steel Short Pitch Conveyor Chains for Popsicle Ice Machine, it is essential to find the right match for optimal performance. Our company provides a diverse selection of sprockets to cater to your specific needs.

Our sprockets are designed and produced using high-quality materials to ensure durability and long-lasting functionality. With a variety of sizes and tooth configurations available, you can easily find the appropriate sprocket to complement your 16ASS Stainless Steel Short Pitch Conveyor Chains for Popsicle Ice Machine.

Whether you need standard sprockets, custom options, or specialized sprockets for unique situations, we are equipped to assist you. Our comprehensive range and expertise in sprocket manufacturing make us the preferred choice for all your sprocket requirements.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...