In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications

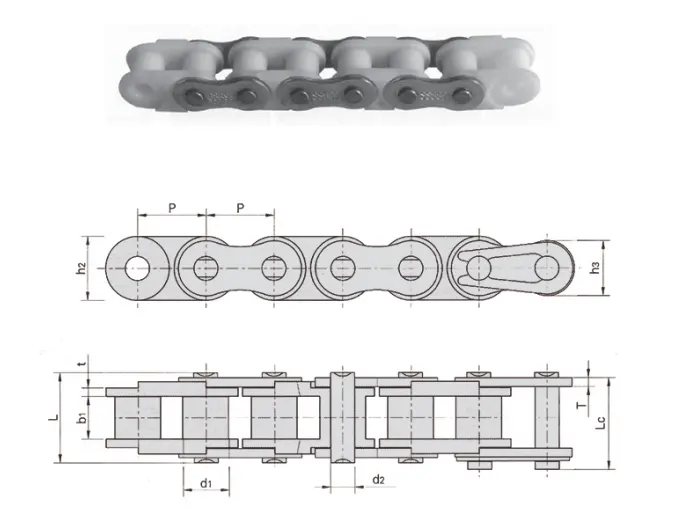

This 16ASpaSS Stainless Steel Engineering Plastic Combination Chains is equipped with the following specifications:

| Chain No. |

Pitch | Roller diameter | Width between inner plates |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

UItimate tensile strength |

|

| P | d1(max) | bl(min) | d2(max) | L(max) | Lc(max) | h2(max) | h3(max) | T(max) | Q(min) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | |

| 04CSPaSS | 6.35 | 3.3 | 3.1 | 2.31 | 7.9 | 8.4 | 6 | 5.06 | 0.8 | 0.42/95.2 |

| 06CSPaSS | 9.525 | 5.08 | 4.68 | 3.58 | 12.4 | 13.2 | 9 | 7.8 | 1.3 | 0.77/175 |

| 08ASPaSS | 12.7 | 7.92 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 10.4 | 1.5 | 1.75/397.6 |

| 10ASPaSS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.1 | 13 | 2.03 | 2.45/556.5 |

| 12ASpaSS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 15.6 | 2.42 | 3.15/716 |

| 16ASpaSS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 20.5 | 3.25 | 5.25/716.1 |

| 08BSPaSS | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 10.6 | 1,60 | 1.75/397.6 |

| 10BSPaSS | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 13.7 | 1.7 | 2.45/556.5 |

| 12BSpaSS | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 15 | 1.85 | 2.94/716.1 |

| 16BSpaSS | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 21 | 4.15/3.1 | 5.25/716.1 |

Introduction

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains represent a high-quality and innovative solution extensively utilized across various sectors. Crafted from stainless steel and engineering plastic, these chains guarantee durability and strength. They are engineered to perform reliably and efficiently, even in challenging conditions. The chains feature exceptional benefits, such as high load capacity, corrosion resistance, and low friction, making them perfect for heavy-duty applications.

Design and Construction

The unique design and construction of the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains distinguish them from typical chains. Utilizing premium stainless steel and engineering plastic, these chains are both robust and durable. They are available in a variety of sizes and lengths to suit the specific requirements of diverse applications. Additionally, they are constructed with precision to ensure optimal operation.

Features and Benefits

High Load Capacity

A prominent advantage of the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains is their exceptional load capacity. They are capable of handling substantial loads without risk of breaking, making them ideal for demanding applications.

Corrosion Resistance

Built with high-grade stainless steel, these chains boast excellent resistance to corrosion. They can endure harsh environmental conditions, including exposure to chemicals or saltwater, without succumbing to rust or degradation.

Low Friction

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains possess a low friction coefficient, making them suitable for environments where reduced friction is critical. They function smoothly and efficiently, minimizing wear on both the chains and accompanying components.

Long Service Life

Designed for longevity, these chains are constructed with durable materials, allowing them to endure years of heavy use without the need for frequent repairs or replacements.

Applications

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains find extensive applications across various industries. Commonly used in food processing, packaging, material handling, and automotive sectors, they are also effective in harsh environments, such as offshore drilling platforms and mining operations.

The 16ASpaSS Stainless Steel Engineering Plastic Combination Chains are a high-quality, innovative choice, providing numerous advantages. They are tailored for reliable performance in heavy-duty situations, constructed from top-tier materials that ensure their strength and durability. Suitable for a range of industries and adverse environments, these chains represent an excellent option for those seeking high-performance solutions.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV serves as the official sales representative for Ever-power Group in the Netherlands. We take pride in our partnership with this reputable company and are dedicated to delivering their premium products to our clients.

Among our key products is the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains, meticulously designed for durability and precision, making them suitable for various industrial applications.

What differentiates us is our unwavering commitment to exceptional product quality and superior service. Our stainless steel roller chains are produced using the highest quality materials and the latest manufacturing technology, ensuring reliability and durability.

In addition to our exclusive product line, we offer a comprehensive selection of stainless steel roller chains to meet diverse customer requirements, providing a wide array of choices.

To illustrate our capabilities, below is an image showcasing our manufacturing strength:

Sprockets for Sale

For those seeking suitable sprockets for engineering applications, the 16ASpaSS Stainless Steel Engineering Plastic Combination Chains present an excellent starting point. Renowned for their durability and corrosion resistance, this chain type is well-suited for numerous uses.

Selecting the appropriate sprockets to complement your 16ASpaSS chain is essential for optimal performance and longevity. Our company provides a range of sprockets, including options made from stainless steel, carbon steel, and various other materials, available in different sizes and tooth counts to meet specific requirements.

Whether you need standard or customized sprockets, we have a solution that suits your needs. Our expert team is ready to assist you in choosing the ideal sprockets for your applications to ensure reliability and peak performance.

To explore our sprocket offerings, please reach out to us today. We look forward to collaborating with you to find the perfect solution for your engineering needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...