In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications

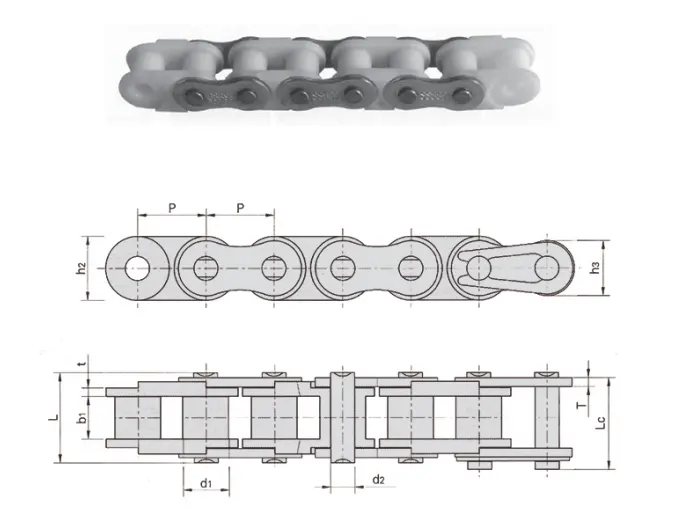

The 12BSpaSS Stainless Steel Engineering Plastic Combination Chains come with the following specifications:

| Chain No. |

Pitch | Roller diameter | Width between inner plates |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Ultimate tensile strength |

|

| P | d1(max) | bl(min) | d2(max) | L(max) | Lc(max) | h2(max) | h3(max) | T(max) | Q(min) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | |

| 04CSPaSS | 6.35 | 3.3 | 3.1 | 2.31 | 7.9 | 8.4 | 6 | 5.06 | 0.8 | 0.42/95.2 |

| 06CSPaSS | 9.525 | 5.08 | 4.68 | 3.58 | 12.4 | 13.2 | 9 | 7.8 | 1.3 | 0.77/175 |

| 08ASPaSS | 12.7 | 7.92 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 10.4 | 1.5 | 1.75/397.6 |

| 10ASPaSS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.1 | 13 | 2.03 | 2.45/556.5 |

| 12ASPaSS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 15.6 | 2.42 | 3.15/716 |

| 16ASPaSS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 20.5 | 3.25 | 5.25/716.1 |

| 08BSPaSS | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 10.6 | 1,60 | 1.75/397.6 |

| 10BSPaSS | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 13.7 | 1.7 | 2.45/556.5 |

| 12BSpaSS | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 15 | 1.85 | 2.94/716.1 |

| 16BSpaSS | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 21 | 4.15/3.1 | 5.25/716.1 |

Introduction

The 12BSpaSS Stainless Steel Engineering Plastic Combination Chains represent a premium offering that merges the remarkable strength of stainless steel with the adaptability of engineering plastic. These chains are engineered to deliver outstanding performance across a variety of applications, such as conveyor systems and food processing machinery.

Construction

Crafted from high-quality stainless steel and engineering plastic, the 12BSpaSS Stainless Steel Engineering Plastic Combination Chains boast superior strength along with resistance to corrosion. The engineering plastic component provides flexibility and resilience against impacts. The synergy of these materials culminates in a lightweight chain that does not compromise on strength or durability, and is easy to handle.

Design Features

A standout element of the 12BSpaSS Stainless Steel Engineering Plastic Combination Chains is their performance in extreme temperatures. Capable of functioning in conditions ranging from -40°C to 120°C, these chains are suited for diverse environments. Furthermore, their self-lubricating mechanism minimizes friction and wear, significantly prolonging the lifespan of the chain.

Applications

The 12BSpaSS Stainless Steel Engineering Plastic Combination Chains are ideal for numerous applications, including conveyor systems and food processing equipment. They are particularly well-suited for challenging environments found in chemical and pharmaceutical sectors.

Benefits

- Exceptional strength and durability

- Lightweight design for easy handling

- Self-lubricating feature reduces wear and friction

- Operates effectively in extreme temperature ranges (-40°C to 120°C)

- Versatile use across a multitude of applications and settings

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV serves as the authorized sales representative for Ever-power Group in the Netherlands. We take pride in offering our outstanding product, the 12BSpaSS Stainless Steel Engineering Plastic Combination Chains, which is a testament to our unique advantages.

Our stainless steel roller chains are distinguished by their unmatched reliability, quality, and durability. You can anticipate exceptional performance from our chains, even in the most demanding conditions. We emphasize precision in engineering and utilize cutting-edge manufacturing processes to ensure that our chains adhere to the highest industry benchmarks.

Additionally, our dedication to customer satisfaction differentiates us from our rivals. We offer superior pre-sales and post-sales support, making sure your requirements are addressed throughout the entire process. Our responsive and knowledgeable team is always prepared to assist with any queries or technical assistance you may need.

Within our advanced manufacturing facility, we possess the capability and know-how to satisfy your stainless steel roller chain needs. We enforce stringent quality control measures throughout production, ensuring that our chains consistently surpass expectations. Our skilled workforce, combined with advanced machinery, allows us to manage orders of any complexity and size.

Alongside the 12BSpaSS Stainless Steel Engineering Plastic Combination Chains, we provide a comprehensive selection of other stainless steel roller chains. Whether you require chains for industrial machinery, automotive uses, or other applications, we have tailored solutions to meet your specific needs.

Sprockets for Sale

For those in search of the ideal chain sprocket to complement your 12BSpaSS Stainless Steel Engineering Plastic Combination Chain, our extensive selection of sprockets is sure to meet your needs. We provide a diverse array of sprocket types, varying in size and tooth count, to ensure you find the perfect match for your requirements.

Our expert team is available to guide you in selecting the most suitable sprocket for your application, whether it be a standard roller chain sprocket or a specialized variant. We are committed to assisting our customers in securing the right solutions for their individual needs, backed by our broad inventory of sprockets.

We take pride in offering high-quality sprockets that are built for durability and reliability. Whether you need a sprocket for a new piece of machinery or a replacement for an existing one, our extensive range of sprockets has you covered.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...