In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications

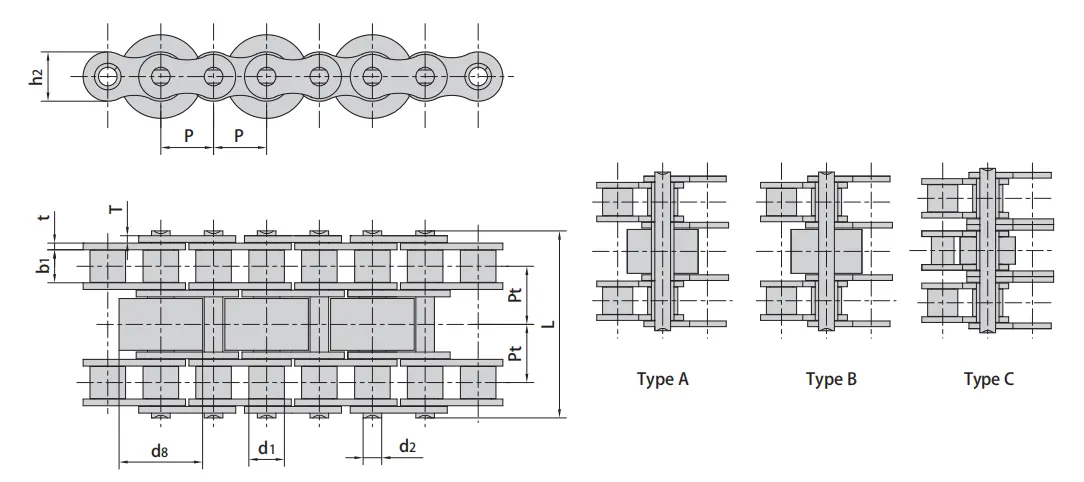

The 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain with Special Rollers has the following parameters:

| Chain No. |

Pitch | Roller diameter |

Width between inner plates |

Pin diameter |

Pin length |

Plate dimension |

Transverse pitch | UItimate tensile strength |

Average tensile strength | Type | ||

| P | d1 max(mm) |

d8 max(mm) |

bl min(mm) |

d2 max(mm) |

L max(mm) |

h2 max(mm) |

t/T max(mm) |

Pt(mm) | Q min(KN) |

Q0 min(KN) |

Q0 min(KN) |

|

| 06BS-3-C15/P15SS | 9.525 | 6.35 | 15 | 5.72 | 3.28 | 33.5 | 8.2 | 1.3 | 10.24 | 11.83/2688.7 | 13.09 | B |

| A06BF3S-3-C15/P15SS | 9.525 | 6.35 | 15 | 5.72 | 3.28 | 33.5 | 8.4 | 1.3 | 10.24 | 11.83/2688.7 | 13.09 | B |

| 08BS-3-45-C16SS | 12.7 | 8.51 | 16 | 7.75 | 4.45 | 45.1 | 11.8 | 1.6 | 13.92 | 22.4/5091.1 | 27.09 | A |

| 08BS-3-45-C17SS | 12.7 | 8.51 | 17 | 7.75 | 4.45 | 45.1 | 11.8 | 1.6 | 13.92 | 22.4/5091.1 | 27.09 | A |

| 08BS-3-45-C20SS | 12.7 | 8.51 | 20 | 7.75 | 445 | 45.1 | 11.8 | 1.6 | 13.92 | 22.4/5091.1 | 27.09 | A |

| 08BSF6-3-45-C20SS | 12.7 | 8.51 | 20 | 7.75 | 4.45 | 45.1 | 11.8 | 1.6 | 13.92 | 22.4/5091.1 | 27.09 | B |

| 12AF90-3-71-C28SS | 19.05 | 11.91 | 28 | 12.57 | 5.94 | 71.5 | 18 | 2.42 | 22.78 | 43.82/2851.1 | 57.4 | B |

| 12BS-3-62-C28/P28SS | 19.05 | 12.07 | 28 | 11.68 | 5.72 | 61.5 | 16 | 1.85 | 19.46 | 40.46/9195.2 | 46.27 | A |

| 12BS-3-62-C31SS | 19.05 | 12.07 | 31 | 11.68 | 5.72 | 61.5 | 16 | 1.85 | 19.46 | 40.46/9195.2 | 46.27 | B |

| 12BSF10-3-62-C26SS | 19.05 | 12.07 | 26 | 11.68 | 5.72 | 61.5 | 16 | 1.85 | 19.46 | 60.69/6793.5 | 71.26 | C |

| 12BSF10-3-62-C28SS | 19.05 | 12.07 | 28 | 11.68 | 5.72 | 61.5 | 16 | 1.85 | 19.46 | 60.69/13794.2 | 71.26 | C |

| 12BF45-3-C28/P28SS | 19.05 | 12.07 | 28 | 11.68 | 5.72 | 61.5 | 16 | 1.85 | 19.46 | 40.46/9195.2 | 46.27 | B |

Title 1: Introduction to 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain

In this section, we will provide an overview of the 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain. This chain is specially designed for industrial applications that require durability, reliability, and resistance to corrosion. It is commonly used in industries such as food processing, pharmaceuticals, and chemical manufacturing.

Title 2: Features of 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain

1. Corrosion Resistance: The chain is made of high-quality stainless steel, which offers excellent resistance to corrosion caused by chemicals, moisture, and extreme temperatures.

2. Special Rollers: The 12BS-3-62-C28/P28SS chain is equipped with special rollers that ensure smooth and efficient movement, reducing friction and wear on the chain and other components.

3. High Load Capacity: This conveyor chain is designed to withstand heavy loads, making it suitable for applications that involve transporting heavy or bulky items.

4. Low Maintenance: With its durable construction and high-quality materials, the 12BS-3-62-C28/P28SS chain requires minimal maintenance, resulting in reduced downtime and increased productivity.

5. Wide Temperature Range: The chain can operate effectively in a wide temperature range, from freezing temperatures to high heat environments, without compromising its performance.

Title 3: Applications of 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain

The 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain is widely used in various industries for different applications, including:

1. Food Processing: It is ideal for conveying food products, ensuring hygiene and preventing contamination.

2. Pharmaceuticals: The chain meets the strict requirements of the pharmaceutical industry, providing reliable and safe transportation of medications and medical supplies.

3. Chemical Manufacturing: It can withstand exposure to various chemicals, making it suitable for the transportation of chemical products in manufacturing processes.

4. Packaging: The chain is commonly used in packaging lines to transport products efficiently and securely.

Title 4: Installation and Maintenance of 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain

Proper installation and maintenance are essential for ensuring the longevity and optimal performance of the 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain. Here are some guidelines:

1. Installation: Follow the manufacturer's instructions and guidelines for installing the chain, ensuring proper tension and alignment.

2. Lubrication: Apply a suitable lubricant to reduce friction and wear between the chain and the sprockets. Regularly check and replenish the lubricant as needed.

3. Cleaning: Regularly clean the chain to remove debris, dirt, and any contaminants that may affect its performance. Use appropriate cleaning agents and methods recommended by the manufacturer.

4. Inspection: Periodically inspect the chain for signs of wear, damage, or misalignment. Replace any worn-out or damaged components promptly.

Title 5: Conclusion

The 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain with Special Rollers is a reliable and high-performance solution for industrial conveyor systems. Its corrosion resistance, special rollers, high load capacity, and low maintenance requirements make it a preferred choice for various applications. With proper installation and regular maintenance, this chain will ensure efficient and trouble-free operation, contributing to the overall productivity and success of your industrial processes.

Choose Our Stainless Steel Roller Chains

RP Techniek BV, as the Dutch sales agent of Ever-power Group, proudly presents our exceptional stainless steel roller chains. Among them, the 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain with Special Rollers stands out, showcasing our unique selling points and highlighting the superior quality and service of our products. With our strong manufacturing capabilities, we ensure that every chain meets the highest standards.

Moreover, we offer a wide range of other types of stainless steel roller chains for sale. Whether you need chains for industrial applications or specific requirements, we have them all. Trust in our expertise and choose our stainless steel roller chains for their reliability, durability, and excellent performance.

Sprockets for Sale

If you're looking for a reliable and high-quality chain and sprocket combination, look no further than the 12BS-3-62-C28/P28SS Stainless Steel Conveyor Chain with Special Rollers. This chain is designed to work seamlessly with a variety of different sprockets, including those made from stainless steel, plastic, and other materials.

At our company, we offer a wide range of sprockets to fit your specific needs. From standard sizes to custom designs, we have the expertise and experience to create the perfect sprocket for your application. Our sprockets are made from the highest quality materials and are built to last, ensuring that your equipment runs smoothly and efficiently.

No matter what type of sprocket you need, we have you covered. Our selection includes everything from standard designs to custom-built solutions, and we offer sprockets in a range of materials, including stainless steel, plastic, and more. So if you're in the market for a new sprocket, be sure to check out our selection today.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...