Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

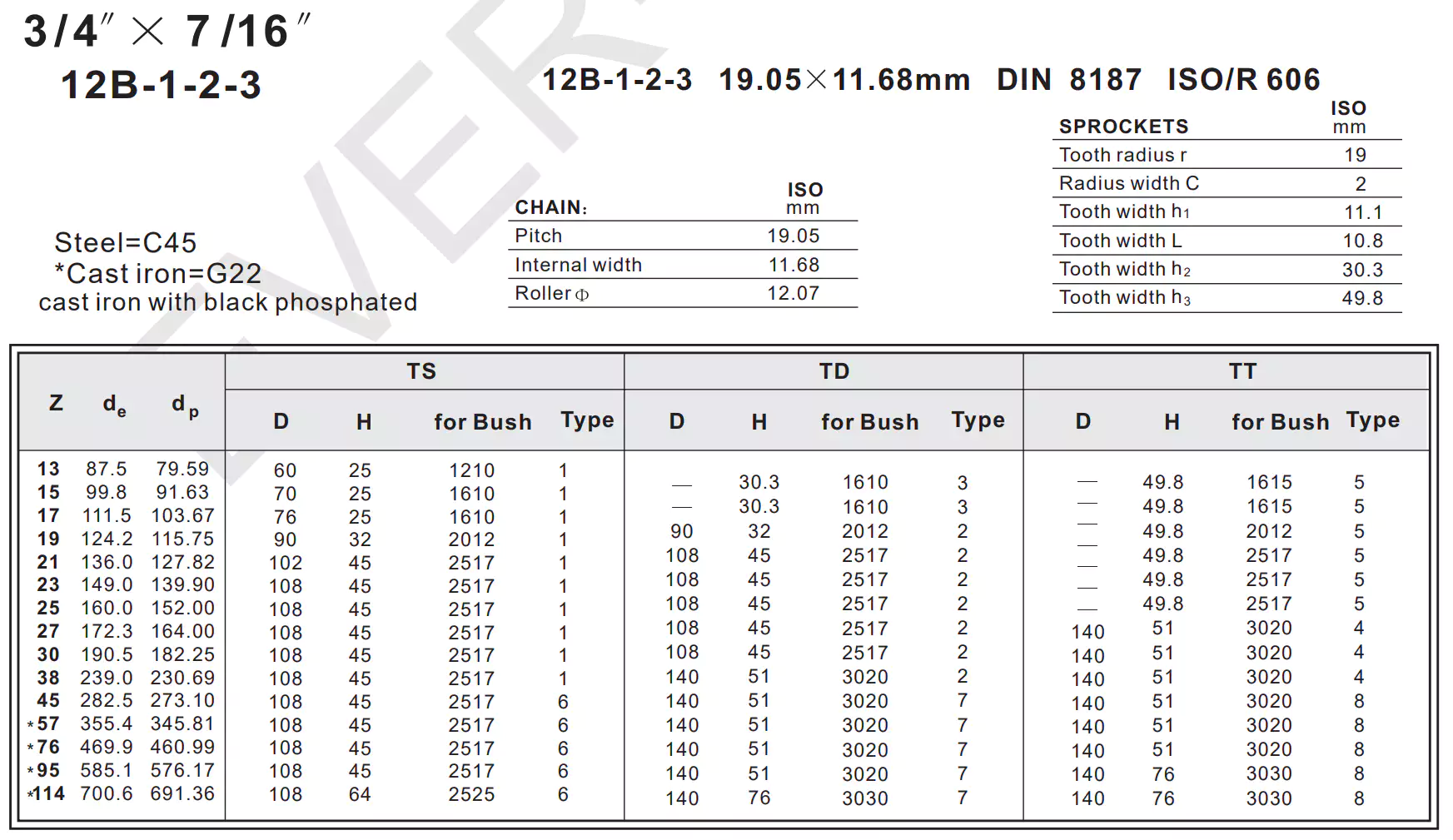

12B-1-2-3 3/4″ Taper Lock Sprocket

The 12B-1-2-3 3/4″ Taper Lock Sprocket is designed for efficient power transmission and reliable performance in various industrial applications. Its taper lock design ensures easy installation and removal, while its durable construction provides longevity and strength. Ideal for heavy-duty operations, this sprocket enhances the reliability of your machinery.

12B-1-2-3 3/4" Taper Lock Sprocket Specifications

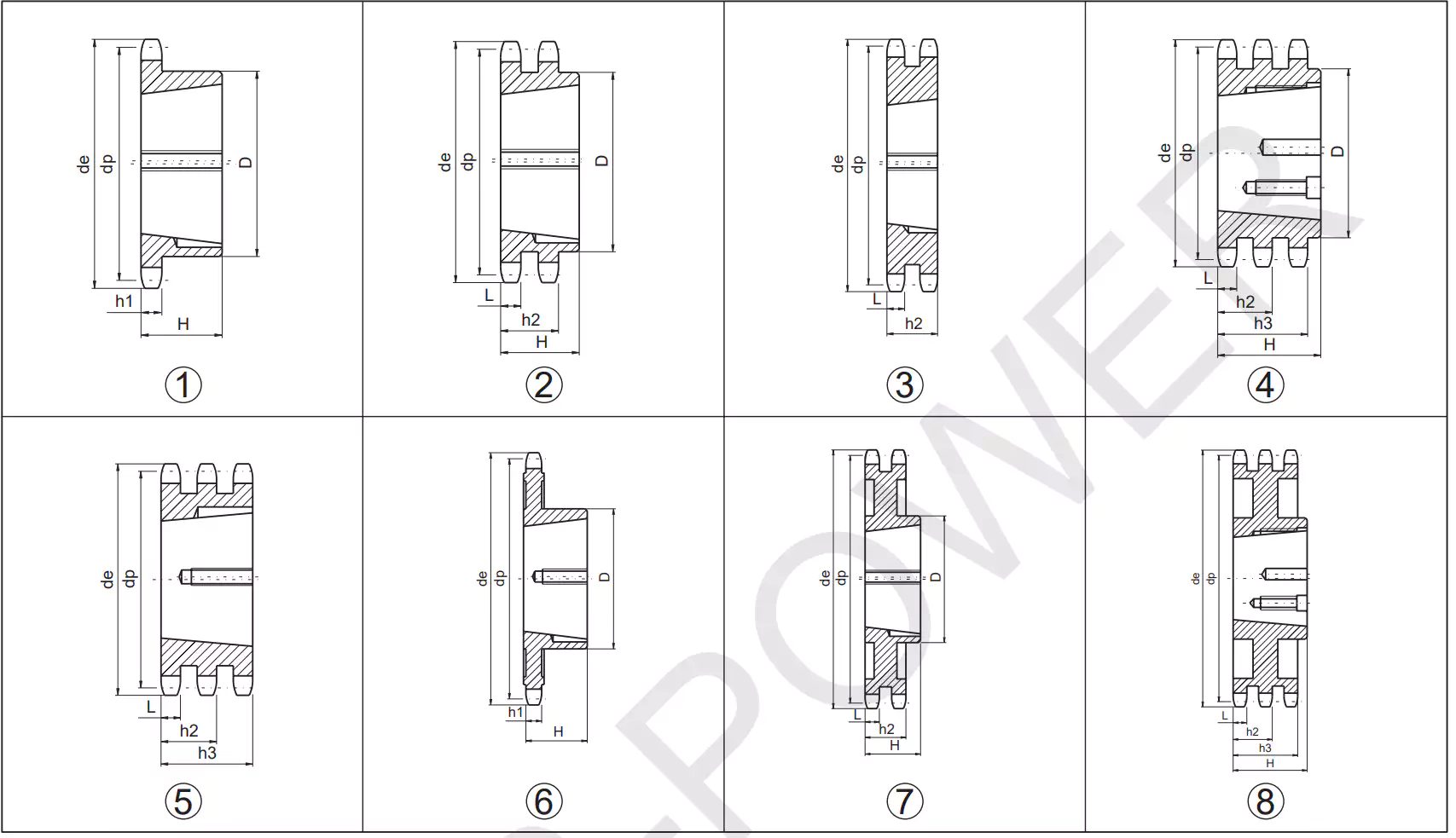

The Taper Lock Sprocket 12B-1-2-3 European Standard represents an advanced type of sprocket that employs a taper lock mechanism, simplifying the process of installation and removal. This design is widely utilized in numerous transmission systems across various industries, ensuring efficient operation and ease of maintenance.

Definition and Basic Structure

The Taper Lock Sprocket is distinguished by its unique tapered bore design. This feature allows it to fit securely onto a corresponding tapered bushing, establishing a strong and precise connection. The sprocket is equipped with teeth that interact with the chain, effectively transmitting rotational motion throughout the system. This design ensures that the sprocket operates smoothly and efficiently in various mechanical applications.

Characteristics and Functions

- Easy Installation: The taper lock design facilitates a straightforward and quick installation process onto the bushing, significantly reducing the time and effort required for setup.

- High Precision Positioning: The taper lock connection guarantees accurate alignment, which is crucial in minimizing the risk of misalignment during operational tasks.

- Wide Applicability: Taper Lock Sprockets are highly versatile and can be employed in a range of transmission systems, making them adaptable to different industrial applications.

- Reliability: The secure taper lock connection ensures a stable attachment, reducing the chances of slippage or disengagement during operation.

- Low Maintenance Cost: Due to their reliable construction and connection, taper lock sprockets contribute to lower maintenance costs over time, enhancing operational efficiency.

Installation and Removal Process

- Prepare Tools and Materials: Collect all necessary tools and materials for the installation, including the taper lock bushing, sprocket, and locking nut to ensure a smooth process.

- Clean Shaft and Sprocket Surface: Thoroughly clean the surface of the shaft and the sprocket to eliminate any dirt, debris, or contaminants that could impair the connection.

- Place Taper Lock Bushing: Carefully slide the taper lock bushing onto the shaft, ensuring it is positioned correctly to avoid any operational issues.

- Install Sprocket: Position the sprocket onto the bushing, making sure to align the teeth accurately with the chain for effective engagement.

- Tighten Locking Nut: Use appropriate tools to securely tighten the locking nut, ensuring that the sprocket is firmly held in place for reliable operation.

Manufacturing Process of Taper Lock Sprockets

- Prepare Raw Materials: Gather all required raw materials necessary for the entire manufacturing process of the sprockets.

- Cutting: Cut the raw materials into the desired shape and dimensions according to the specifications.

- Forging or Casting: Depending on the selected manufacturing technique, the sprocket can be either forged or cast to obtain the desired design and structure.

- Machining: Utilize machining processes to refine the dimensions of the sprocket and accurately create the tooth profiles.

- Teeth Rolling: Roll the teeth onto the sprocket to guarantee precise and sturdy engagement with the chain during operation.

- Heat Treatment: Implement heat treatment procedures to enhance the hardness and overall strength of the sprocket.

- Surface Treatment: Conduct surface treatments like coating or plating to improve the sprocket's corrosion resistance and overall appearance.

- Quality Inspection: Perform comprehensive quality inspections to ensure that all sprockets meet the established industry standards for performance and durability.

Sprockets Supplier in Netherlands

RP Techniek BV takes pride in being the dedicated sales agent for Ever-power Group in the Netherlands, recognized for its manufacturing of premium mechanical components. One of our premier products is the 12B-1-2-3 3/4" Taper Bore Sprocket, engineered for outstanding performance in diverse industrial applications. Our sprockets are crafted from high-quality, durable materials to ensure long-lasting functionality and reliability, making them essential components for various machinery types.

Alongside our standard sprocket offerings, we also excel in providing custom solutions tailored to meet specific customer requirements. If you have particular dimensions or design preferences, our expert team is available to assist you in creating custom sprockets that align perfectly with your needs. We encourage all clients to share their drawings or samples for personalized orders.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...