In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

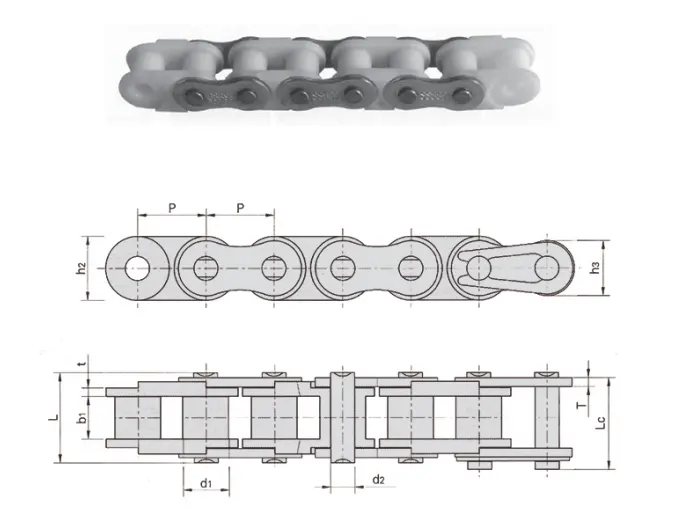

Specifications - 10BSPaSS Stainless Steel Engineering Plastic Combination Chains

This chain possesses the following specifications:

| Chain No. |

Pitch | Roller diameter | Width between inner plates |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Ultimate tensile strength |

|

| P | d1(max) | bl(min) | d2(max) | L(max) | Lc(max) | h2(max) | h3(max) | T(max) | Q(min) | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | KN/LB | |

| 04CSPaSS | 6.35 | 3.3 | 3.1 | 2.31 | 7.9 | 8.4 | 6 | 5.06 | 0.8 | 0.42/95.2 |

| 06CSPaSS | 9.525 | 5.08 | 4.68 | 3.58 | 12.4 | 13.2 | 9 | 7.8 | 1.3 | 0.77/175 |

| 08ASPaSS | 12.7 | 7.92 | 7.85 | 3.96 | 16.6 | 17.8 | 12 | 10.4 | 1.5 | 1.75/397.6 |

| 10ASPaSS | 15.875 | 10.16 | 9.4 | 5.08 | 20.7 | 22.2 | 15.1 | 13 | 2.03 | 2.45/556.5 |

| 12ASpaSS | 19.05 | 11.91 | 12.57 | 5.94 | 25.9 | 27.7 | 18 | 15.6 | 2.42 | 3.15/716 |

| 16ASpaSS | 25.4 | 15.88 | 15.75 | 7.92 | 32.7 | 35 | 24 | 20.5 | 3.25 | 5.25/716.1 |

| 08BSPaSS | 12.7 | 8.51 | 7.75 | 4.45 | 16.7 | 18.2 | 11.8 | 10.6 | 1,60 | 1.75/397.6 |

| 10BSPaSS | 15.875 | 10.16 | 9.65 | 5.08 | 19.5 | 20.9 | 14.7 | 13.7 | 1.7 | 2.45/556.5 |

| 12BSpaSS | 19.05 | 12.07 | 11.68 | 5.72 | 22.5 | 24.2 | 16 | 15 | 1.85 | 2.94/716.1 |

| 16BSpaSS | 25.4 | 15.88 | 17.02 | 8.28 | 36.1 | 37.4 | 21 | 21 | 4.15/3.1 | 5.25/716.1 |

1. Overview of 10BSPaSS Stainless Steel Engineering Plastic Combination Chains

The 10BSPaSS stainless steel engineering plastic combination chains are expertly crafted to deliver outstanding performance and longevity. By merging the durability of stainless steel with the adaptability of engineering plastic, these chains present a versatile choice for a multitude of applications in sectors like manufacturing, automation, and logistics.

2. Unparalleled Strength and Durability

These chains provide exceptional strength and durability due to their unique composition of stainless steel and engineering plastic. The stainless steel core guarantees high tensile strength, while the plastic components improve flexibility and enhance resistance to wear. This perfect blend enables the chains to support heavy loads and endure challenging operational conditions, making them suitable for demanding industrial settings.

3. Enhanced Corrosion Resistance

A key highlight of the 10BSPaSS stainless steel engineering plastic combination chains is their remarkable corrosion resistance. The stainless steel core is designed to resist rust and corrosion effectively, allowing the chains to maintain their peak performance even in corrosive environments, such as chemical processing or marine applications. This feature significantly prolongs the service life of the chains, leading to lower maintenance costs and minimal downtime.

4. Versatile Application Range

These combination chains are intended for a broad spectrum of applications. Whether for transporting heavy materials, functioning under extreme temperatures, or maneuvering through complex assembly lines, these chains provide reliable performance. Their adaptability makes them ideal for industries such as automotive, food processing, pharmaceuticals, and beyond.

5. Customization Options

Recognizing the varied needs of different industries, the 10BSPaSS stainless steel engineering plastic combination chains offer significant customization possibilities. Options include modifications in chain length and pitch, along with specific attachments and coatings, ensuring these chains meet unique requirements. This level of customization ensures optimal performance and effectiveness in various applications, catering to businesses seeking specific solutions.

With their unbeatable blend of strength, durability, corrosion resistance, versatility, and customization options, the 10BSPaSS stainless steel engineering plastic combination chains are a dependable and efficient solution for diverse industries. Consider embracing these exceptional chains to enhance your operational performance.

Why Choose Our Stainless Steel Roller Chains?

RP Techniek BV, as the Dutch sales representative for Ever-power Group, proudly presents a broad selection of stainless steel roller chains. Among these, the 10BSPaSS Stainless Steel Engineering Plastic Combination Chains stand out as a premier product.

Our chains are recognized for their superior quality and robustness, making them a trustworthy option for various uses. The blend of stainless steel and engineering plastic provides a unique combination of strength and adaptability, ensuring optimal performance even in demanding conditions.

At RP Techniek BV, we are dedicated to client satisfaction and strive to deliver excellent service. Our experienced team is always available to help you find the ideal chain tailored to your specific needs. We appreciate the significance of dependable products and aim to surpass your expectations with our high-quality stainless steel roller chains.

Moreover, we take pride in our solid manufacturing capabilities. Utilizing advanced technology and rigorous quality control processes, we guarantee that our chains adhere to the highest standards. This allows us to provide chains that are durable and resistant to corrosion and wear.

In addition to the 10BSPaSS Stainless Steel Engineering Plastic Combination Chains, we offer an extensive range of other stainless steel roller chains. Whether you need chains for industrial machinery, conveyors, or other applications, we have the solution to meet your requirements.

Please view the image below for a glimpse of our premium stainless steel roller chains.

Sprockets for Sale

When seeking the perfect pairing for your 10BSPaSS stainless steel engineering plastic chains, explore our comprehensive range of sprockets. Our company provides a variety of sprocket types to fulfill your requirements.

Our sprockets are crafted with precision and durability in mind. Whether you need a small sprocket for a light application or a larger one for heavy-duty operations, we have the right option for you. Made from high-quality materials, our sprockets ensure lasting performance and reliability.

With our extensive assortment of sprockets, you can find the ideal match for your 10BSPaSS chains. We provide both standard and specialty sprockets, accommodating various tooth counts, bore sizes, and materials for diverse applications.

Don't settle for less than optimal performance and efficiency for your chains. Choose our sprockets to ensure smooth functionality and maximize the lifespan of your chains. Browse through our extensive catalog to find the perfect sprocket for your needs.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...