Stainless steel gearboxes are widely used in industrial transmission fields due to their high strength and corrosion resistance. However, in actual use, stainless steel gearboxes may still malfunction due to improper design, installation, lubrication or maintenance....

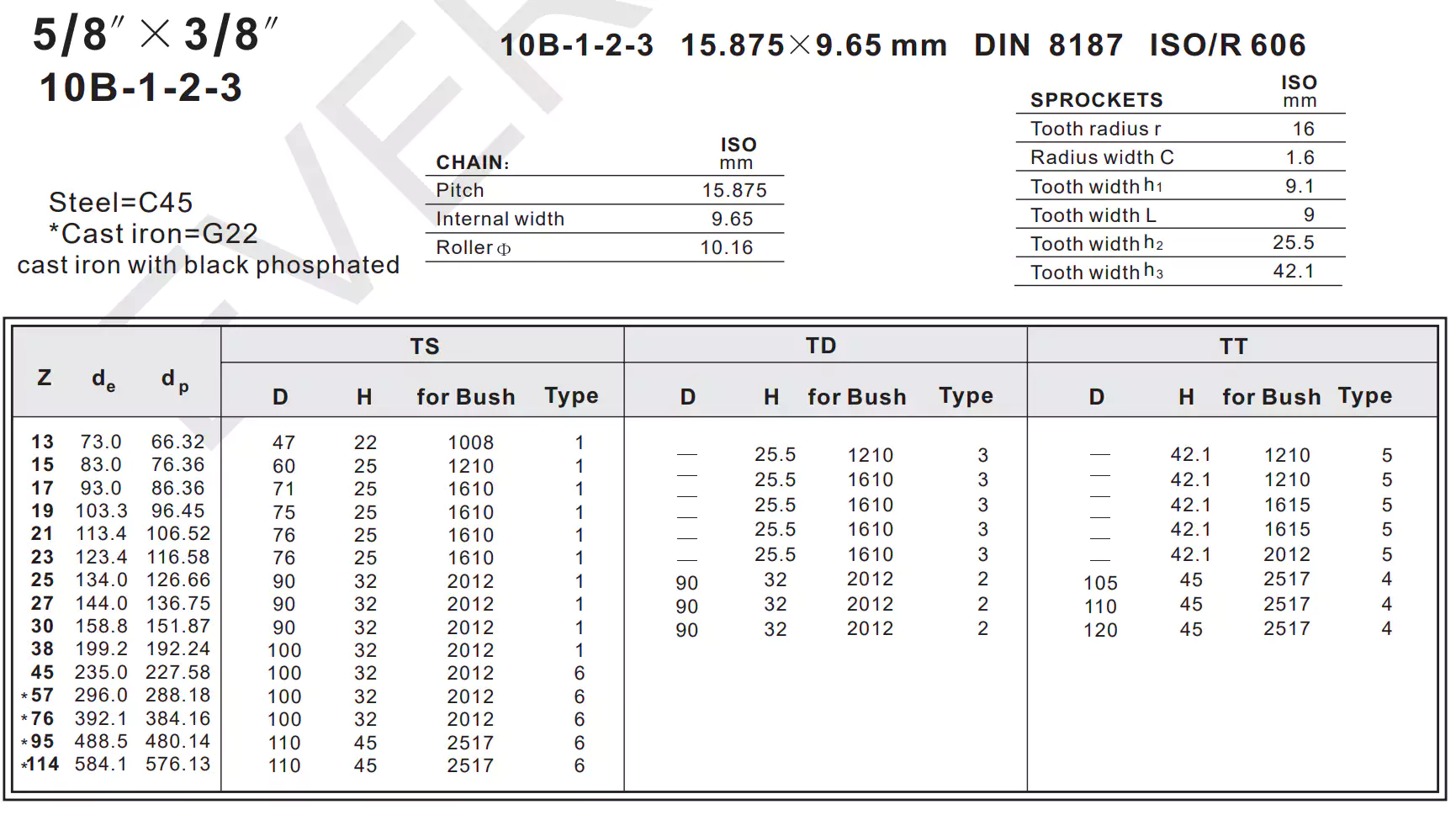

10B-1-2-3 5/8″ Taper Lock Sprocket

The 10B-1-2-3 5/8″ Taper Lock Sprocket is designed for efficient power transmission in industrial applications. Its precision engineering ensures durability and optimal performance, while the taper lock feature allows for easy installation and removal. This sprocket is compatible with various chain sizes, making it a versatile choice for your machinery needs.

Specifications for 10B-1-2-3 5/8" Taper Lock Sprocket

The 10B-1-2-3 5/8" Taper Lock Sprocket is a vital component commonly found in various transmission systems. Its unique taper lock design allows for easy installation and removal, making it a preferred choice for many. This sprocket is effectively utilized in numerous applications where power and motion transmission is essential, ensuring optimal performance and reliability.

Definition and Basic Structure

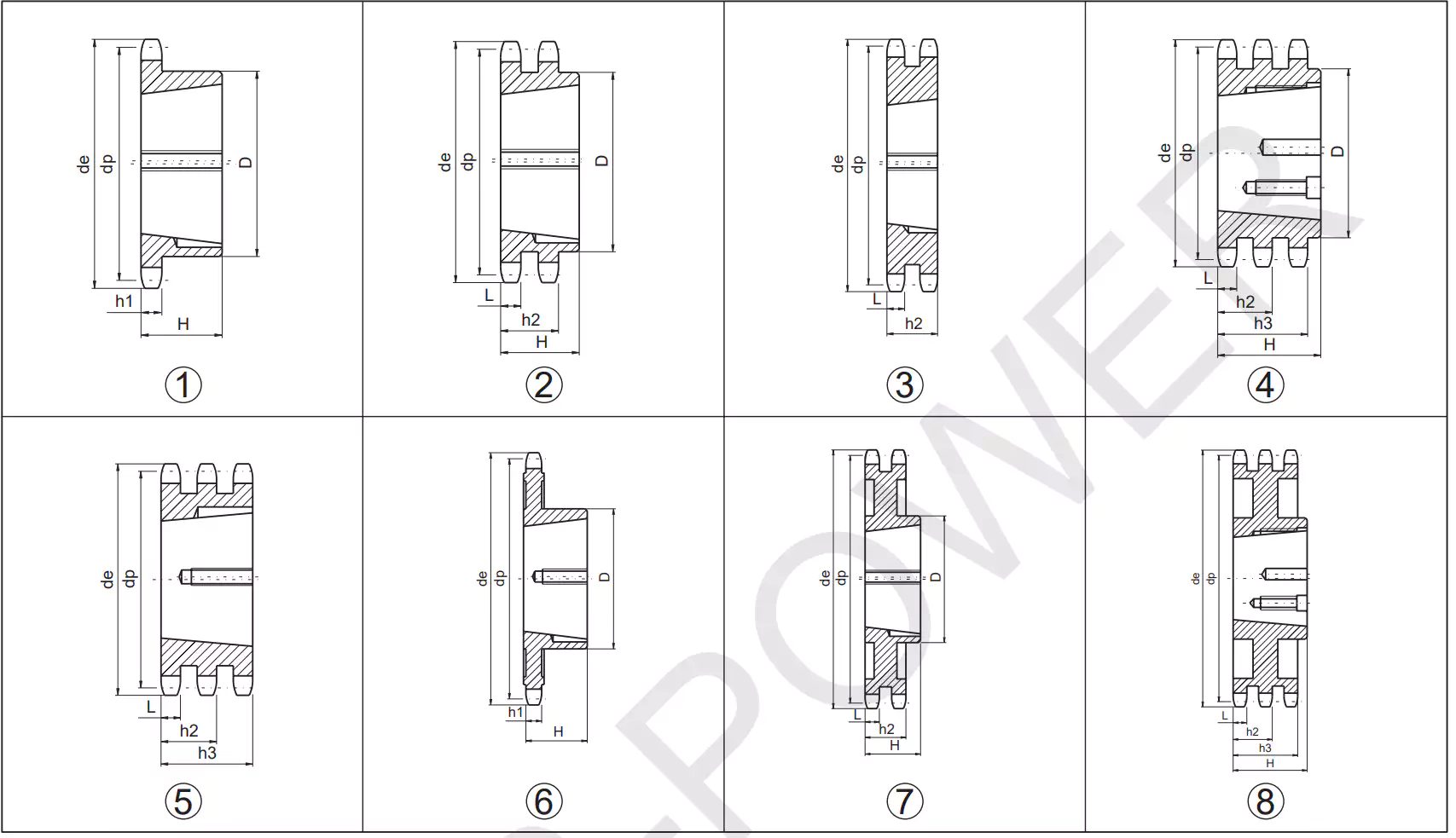

Taper lock sprockets are designed with a tapered bore that facilitates mounting onto a shaft using a taper lock bushing. The basic structure comprises engaging teeth that work with a chain or belt, a hub featuring a tapered bore, and the taper lock bushing that provides a secure and precise fit onto the shaft, enhancing the overall functionality of the sprocket in various applications.

Characteristics and Functions

- Easy Installation: The taper lock design allows for simple installation, enabling quick and efficient mounting onto the shaft without complex procedures.

- High Precision Positioning: With the taper lock bushing, the sprocket achieves a precise fit on the shaft, which is critical for accurate positioning during operation.

- Wide Applicability: These sprockets are incredibly versatile and suitable for a wide range of applications across various industries, making them indispensable components.

- Reliability: The solid construction and secure fit of taper lock sprockets ensure high reliability during power and motion transmission, contributing to system efficiency.

- Low Maintenance Cost: Their design minimizes maintenance needs, leading to significant long-term cost savings for users.

Installation and Removal Process

- Prepare Tools and Materials: Before starting the installation, gather all necessary tools and materials, including the taper lock bushing, sprocket, and the locking nut to ensure a smooth process.

- Clean Shaft and Sprocket Surface: It is essential to clean both the shaft and sprocket surfaces thoroughly to eliminate any debris, which can interfere with proper installation.

- Place Taper Lock Bushing: Carefully slide the taper lock bushing onto the shaft, making sure it is properly aligned for optimal performance.

- Install Sprocket: Position the sprocket onto the taper lock bushing, ensuring the teeth mesh correctly with the corresponding chain or belt for effective power transmission.

- Tighten Locking Nut: Once everything is correctly positioned, securely tighten the locking nut to fix the sprocket in place, ensuring stability during operation.

Manufacturing Process

The manufacturing of taper lock sprockets involves several meticulous steps to ensure optimum quality:

- Raw Material Preparation: Selecting and preparing appropriate raw materials, such as high-quality steel or cast iron, is crucial to the product's durability.

- Cutting: The raw material is cut into the desired dimensions and shapes, forming the foundation for the sprocket.

- Forging or Casting: The basic structure of the sprocket is created using either forging or casting techniques, depending on the design requirements.

- Machining: Subsequent machining processes refine the sprocket's shape and dimensions to meet precise specifications.

- Tooth Rolling: The teeth of the sprocket are formed through a specialized rolling process, ensuring they are robust and properly shaped.

- Heat Treatment: To enhance hardness and strength, the sprocket undergoes heat treatment, significantly improving its performance capabilities.

- Surface Treatment: Surface treatments, such as coatings or plating, are applied to improve corrosion resistance, extending the life of the sprocket in various environments.

- Quality Inspection: A comprehensive quality inspection is conducted to ensure that the sprocket meets all required industry standards and specifications before delivery.

Sprockets Supplier in Netherlands

RP Techniek BV serves as the sales agent for Ever-power Group in the Netherlands, providing top-quality sprockets and related products tailored to various industry needs. Among our extensive product offerings, we feature the 10B-1-2-3 5/8" Taper Lock Sprocket designed for remarkable durability and efficiency in power transmission applications. Utilizing high-grade materials and advanced manufacturing technology, our sprockets are engineered for longevity and optimal performance.

In addition to standard sprockets, we specialize in non-standard customizations designed to meet the specific requirements of our clients. We encourage customers to present their designs and samples for custom orders, ensuring that every sprocket is crafted to perfectly suit their unique operational needs.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Application of CC600 Chain in Logistics Automation in Amsterdam

In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...