In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications

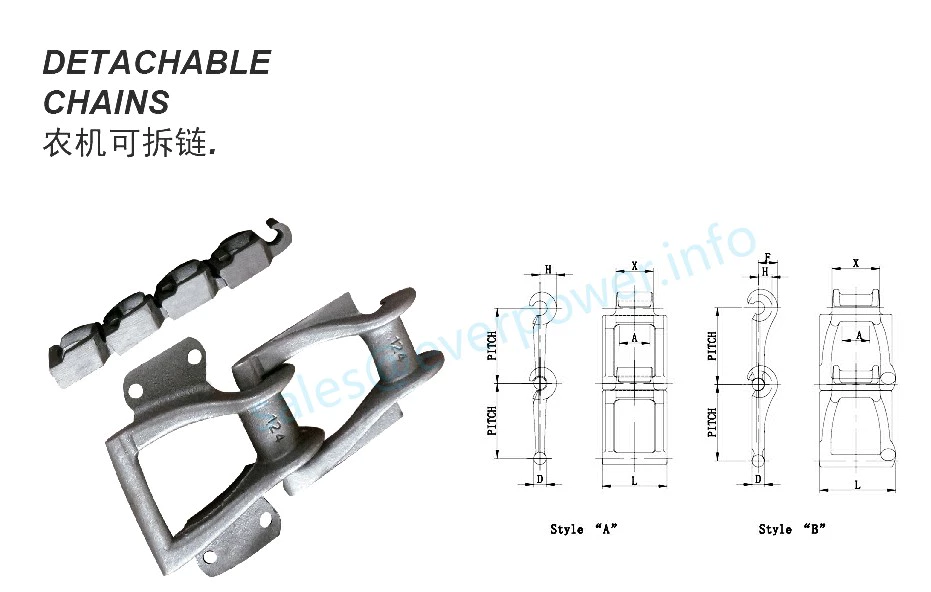

Here are the parameters of the 103 Casting Detachable Chain:

| CHAIN NO. | PITCH IN INCHES |

HEIGHT PER FOOT LBS |

AVERAGE ULTIMATE STRENGTH LBS |

MAXIMUM WORKING LOAD LBS. |

A | C | D | E | ?F | H | ?L | X | AVAILABLE ATTACHMENTS |

| 25 | 0.902 | 2.4 | 700 | 120 | 0.38 | 0.14 | ¡ª¡ª | 0.20 | ?0.78 | 0.41 | A1-R.A1-L | ||

| 32 | 1.154 | 3.5 | 1,100 | 185 | 0.50 | 0.17 | ¡ª¡ª | 0.25 | ?0.97 | 0.58 | A1-R.A1-L.K1 | ||

| 34 | 1.398 | 4.0 | 1.300 | 220 | 0.50 | 0.19 | 1.25 | 0.56 | None | ||||

| 42 | 1.375 | 5.5 | 1.600 | 270 | 0.62 | 0.22 | ¡ª¡ª | 0.28 | 1.28 | 0.77 | A1-R,A1-L.K1 | ||

| 45 | 1.630 | 5.2 | 1.700 | 285 | 0.69 | 0.22 | ¡ª¡ª | 0.30 | ?1.31 | 0.80 | A1-R.A1-L.K1 | ||

| 50 | 1.381 | 7.1 | 1.900 | 320 | 0.63 | 0.27 | 0.33 | ?1.31 | 0.62 | None | |||

| 51 | 1.155 | 7.0 | 1.900 | 320 | 0.56 | 0.27 | ¡ª¡ª | 0.36 | ?1.25 | 0.67 | K1 | ||

| S51 | 1.136 | 7.B | 1.900 | 315 | 0.56 | 0.27 | ¡ª¡ª | 0.30 | ?1.06 | 0.64 | None | ||

| 52 | 1.506 | 8.0 | 2,300 | 385 | 0.62 | 0.27 | ¡ª¡ª | 0.34 | ?1.53 | 0.83 | A1.D5,K1 | ||

| 55 | 1.631 | 7.2 | 2,300 | 385 | 0.69 | 0.27 | ¡ª¡ª | 0.36 | ?1.41 | 0.81 | A1-R/L,D5-R/L,C1.F2,G27-R/L,K1,C | ||

| 57 | 2.308 | 8.7 | 2.900 | 485 | 0.75 | 0.27 | ¡ª¡ª | 0.41 | ?1.81 | 1.09 | A1-R,A1-L.F2 | ||

| 62 | 1.654 | 10.6 | 3.200 | 535 | 0.81 | 0.31 | 0.41 | ?1.66 | 0.97 | A1-R/L,A12-R/L,05-R/L.K1,K2,F2 | |||

| 67 | 2.308 | 8.6 | 2.900 | 485 | 0.69 | 0.31 | ?0.53 | 0.41 | ?2.03 | 1.36 | None | ||

| 75 | 2.609 | 13.4 | 4,100 | 690 | 0.94 | 0.41 | ¡ª¡ª | 0.44 | ?2.09 | 1.12 | D5-R.D5-L | ||

| 77 | 2.297 | 14.5 | 3.600 | 600 | 0.69 | 0.39 | ?0.61 | 0.36 | ?2.22 | 1.42 | A1-R.A1-L.D5.F2,K1 | ||

| 78 | 2.609 | 18.8 | 5.500 | 920 | 0.94 | 0.42 | ?0.66 | 0.44 | ?2.62 | 1.62 | K1 | ||

| 88 | 2.609 | 24.0 | 6.400 | 1,070 | 0.94 | 0.48 | ?0.78 | 0.44 | ?2.75 | 1.78 | F2.K1 | ||

| 103 | 3.075 | 40.0 | 10,000 | 1,670 | 1.12 | 0.58 | ?1.00 | 0.61 | ?3.28 | 2.03 | F2.F8,K1,K2,F2 | ||

| 114 | 3.250 | 53.0 | 12.000 | 2.000 | 1.13 | 0.66 | ?0.17 | 0.81 | ?3.28 | 2.03 | None | ||

| 124 | 4.063 | 66.0 | 17.000 | 2,830 | 1.25 | 0.77 | ?1.31 | 0.68 | ?4.06 | 2.31 | F8.K1,K2 |

Overview

The 103 Casting Detachable Chain is a type of chain used in various industrial applications. It is known for its durability and strength, making it a popular choice in heavy-duty industries such as mining, construction, and agriculture. This detachable chain is designed to be easily assembled and disassembled, making maintenance and repairs a breeze.

Materials Used

The 103 Casting Detachable Chain is made from high-quality materials, including alloy steel and carbon steel. These materials are known for their strength, durability, and resistance to wear and tear. The chain is also coated with a layer of zinc or nickel to protect it from corrosion and rust.

Chain Assembly

Assembling the 103 Casting Detachable Chain is a simple process that can be done quickly and easily. The chain links are designed to easily snap together, and the detachable design allows for easy disassembly when necessary. The chain can be customized to fit specific needs, as additional links can be added or removed as needed.

Applications

The 103 Casting Detachable Chain is used in a variety of industrial applications. It is commonly used in mining operations to transport heavy loads, in construction to lift and hoist heavy equipment, and in agriculture to power machinery. Its durability and strength make it a popular choice for any application that requires a heavy-duty chain.

Maintenance

Maintenance of the 103 Casting Detachable Chain is simple and can be done with basic tools. The chain should be inspected regularly for wear and tear, and any damaged links should be replaced immediately. The chain should also be lubricated regularly to ensure smooth operation.

Conclusion

The 103 Casting Detachable Chain is a high-quality, durable chain that is perfect for heavy-duty industrial applications. Its detachable design makes it easy to assemble and disassemble, and its customizable length allows it to be tailored to specific needs. With proper maintenance, this chain can last for years and can provide reliable service for any industrial application.

Choose Our Malleable Casting Chains

RP Techniek BV is the Netherlands sales agent for Ever-power Group. We specialize in providing high-quality malleable cast iron chains, with our 103 Casting Detachable Chain being a standout product.

Our malleable cast iron chains possess unique selling points that set them apart. From exceptional product quality to outstanding customer service, we prioritize delivering excellence to our clients. We take pride in our strong manufacturing capabilities, ensuring that every chain meets the highest standards.

In addition to our malleable casting chains, we offer a wide range of other casting chains for sale. With various options to choose from, we guarantee to provide the perfect solution for your specific needs.

Sprockets for Sale

When it comes to finding the perfect chain wheel to pair with the 103 Casting Detachable Chain, look no further. Our company offers a wide variety of sprockets for sale to suit your needs.

Whether you require a smaller, more compact sprocket or a larger, heavy-duty one, we have you covered. Our range includes various sizes, materials, and tooth configurations to ensure you find the ideal match for your application.

With our high-quality sprockets, you can expect durability, reliability, and optimal performance. We understand the importance of having a dependable and efficient chain wheel setup, and that's why we provide only the best options for our customers.

Check out the image below to get a glimpse of our top-notch sprockets:

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...