In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

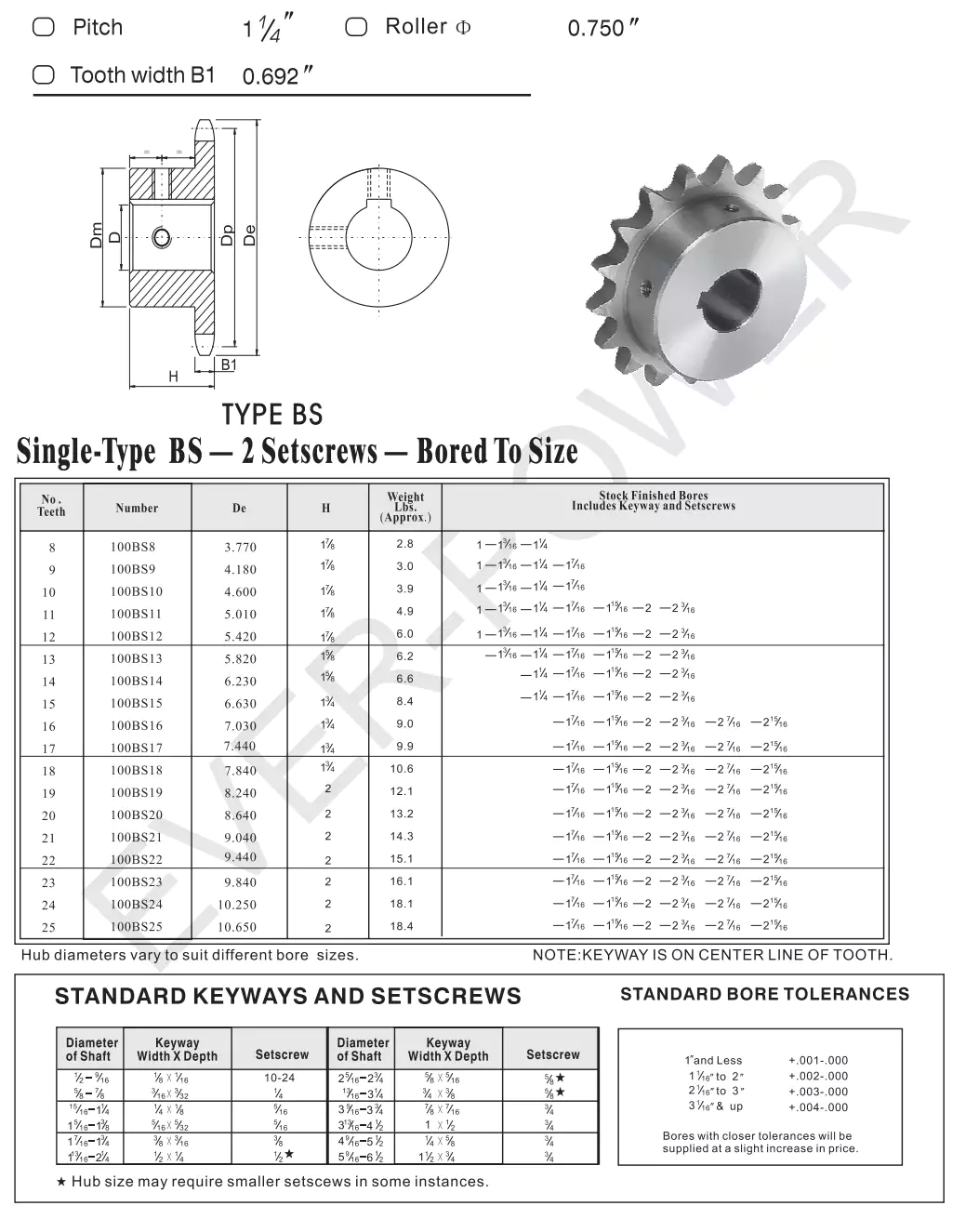

100BS* Finished Bore Sprocket

The 100BS* Finished Bore Sprocket is designed for high-performance applications, ensuring optimal power transmission and durability. Crafted from premium materials, it features precision-engineered teeth for seamless engagement with chains. Its finished bore design allows for easy installation and compatibility with various shaft sizes, making it an ideal choice for industrial machinery.

Specifications of 100BS* Finished Bore Sprocket

The 100BS* Finished Bore Sprocket is designed with precision and engineered for optimal performance in various applications. It is characterized by a pre-bored hole that simplifies the installation process onto a shaft without the need for additional machining, making it a practical choice for power transmission systems.

Materials and Manufacturing Process

The manufacturing of the 100BS* Finished Bore Sprocket utilizes high-quality materials such as high carbon steel, alloy steel, or stainless steel. The production process involves several critical steps, including careful material selection, cutting, stamping, forging, machining, heat treatment, surface hardening, and surface treatment, all followed by rigorous quality control measures. Each stage is executed with precision to ensure that the finished bore sprockets meet the highest standards of quality and durability.

Applications

Finished bore sprockets find extensive use across various sectors, including heavy machinery, food processing, pharmaceuticals, assembly lines, logistics, and warehousing. Their design caters to tasks that require exceptional efficiency and accuracy in power transmission, making them indispensable in these industries.

Maintenance

To ensure that finished bore sprockets continue to perform optimally over time, regular maintenance is crucial. This includes daily inspections to identify any wear or damage, cleaning to remove debris, lubrication of moving parts to reduce friction, adjustments to maintain alignment, and calibrations to ensure accurate functioning. Addressing issues such as tooth skipping, breakage, excessive wear, noise, and chain dropping promptly can significantly enhance the lifespan and efficiency of the sprockets.

Other Types of Sprockets

In addition to the finished bore sprockets, we also provide a wide array of other sprocket types, such as taper lock sprockets, QD sprockets, and idler sprockets, among others. Our extensive inventory also includes a variety of chains designed for different applications, ensuring that we can meet diverse customer needs.

Sprockets Supplier in Netherlands

RP Techniek BV serves as a dedicated sales agent for Ever-power Group in the Netherlands, supplying high-quality industrial components tailored to meet diverse operational requirements. Our product range prominently features the 100BS* Finished Bore Sprocket, which is meticulously crafted to guarantee outstanding performance and durability across various applications. These sprockets are engineered to integrate seamlessly with existing systems, thereby facilitating smooth operations and extending service life.

Beyond standard offerings, we also excel in providing customized solutions based on specific customer requirements. We invite clients to share their drawings or samples, enabling us to develop tailored sprocket solutions that meet unique operational challenges.

Additional information

| Edited | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...