In modern logistics automation systems, the CC600 Crate Conveyor Chain in Amsterdam plays a crucial role. With the continuous development of warehousing and sorting technologies, enterprises have increasingly higher requirements for the stability, efficiency and...

Specifications

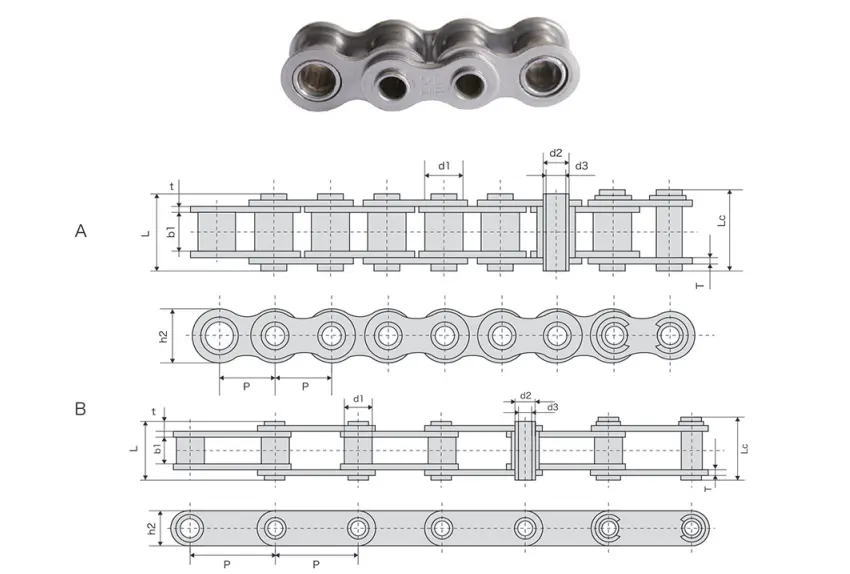

The 08BHPFSS Stainless Steel Hollow Pin Chain comes with the following specifications:

| Chain No |

Pitch | Bush? diameter | Width between inner plates |

Pin diameter |

Pin diameter |

Pin length |

Pin length |

Inner plate depth |

Plate thickness |

Breaking Load |

Weight per meter |

Type |

| P | d1 | bl | d2 | d3 | L | LC | h2 | T | Q | q | ||

| max | min | max | min | max | max | max | max | min | ||||

| mm | mm | mm | mm | mm | Mm | mm | mm | mm | KN | kg/m | ||

| 08BHPFSS | 12.7 | 8.51 | 7.75 | 6.55 | 4.5 | 16.4 | 17.6 | 11.8 | 1.5 | 7.8/1773 | 0.57 | A |

| 40HPSS | 12.7 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.55 | A |

| 50HPSS | 15.875 | 10.16 | 9.4 | 7.03 | 5.13 | 20.7 | 21.9 | 15.09 | 2 | 14.0/3182 | 0.92 | A |

| 60HPSS | 19.05 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 18 | 2.4 | 16.8/3818 | 1.31 | A |

| *12BHPSS | 19.05 | 12.07 | 11.68 | 6.5 | 4 | 21.6 | 22.8 | 15.9 | 1.8 | 16.5/3750 | 1.1 | A |

| 80HPSS | 25.4 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 2.29 | A |

| C2040HPSS | 25.4 | 7.95 | 7.85 | 5.63 | 4 | 16.5 | 17.6 | 12 | 1.5 | 7.7/1750 | 0.47 | B |

| C2050HPSS | 31.75 | 10.16 | 9.4 | 7.22 | 5.12 | 20.5 | 21.8 | 15 | 2 | 14.3/3250 | 0.77 | B |

| C2060HPSS | 38.1 | 11.91 | 12.7 | 8.31 | 6 | 25.8 | 26.8 | 17 | 2.4 | 16.8/3818 | 1.03 | B |

| C2080HPSS | 50.8 | 15.88 | 15.75 | 11.4 | 8.05 | 32.5 | 33.8 | 24 | 3 | 35.0/7955 | 1.83 | B |

| *HB50.8SS | 50.8 | 30 | 10.5 | 11.4 | 8.2 | 27.4 | 28.6 | 26 | 3 | 35.0/7955 | 2.6 |

Introduction

The 08BHPFSS Stainless Steel Hollow Pin Chain is commonly utilized in a variety of industrial settings. Constructed from high-quality stainless steel, this chain offers excellent resistance against corrosion and wear. Its hollow pin design allows for adaptability and straightforward installation within numerous machinery systems.

Product Features

- Stainless steel construction: Made from stainless steel, this chain boasts outstanding resistance to corrosion and wear, making it ideal for harsh conditions.

- Hollow pin design: The chain's hollow pin configuration enhances flexibility and simplifies installation in various machinery. It also facilitates the attachment of different devices or accessories.

- Robust strength: This chain possesses high tensile strength, making it suitable for heavy-duty applications.

- Quiet operation: The chain runs quietly and smoothly, making it perfect for environments where noise reduction is a priority.

- Simplified maintenance: With easy maintenance requirements and minimal lubrication needs, this chain helps lower overall costs and downtime.

Applications

The 08BHPFSS Stainless Steel Hollow Pin Chain is extensively used across various industrial applications, including:

- Food processing and packaging

- Beverage bottling and packaging

- Pharmaceutical manufacturing

- Automotive production

- Chemical processing

Installation and Maintenance

To ensure the optimal performance and durability of the 08BHPFSS Stainless Steel Hollow Pin Chain, proper installation and maintenance are crucial. Here are several important considerations:

- Installation: Ensure the chain is correctly aligned and tensions are properly set prior to use, as improper alignment can lead to premature wear and failure.

- Lubrication: Regularly lubricate the chain to minimize friction and wear, using a high-quality lubricant compatible with stainless steel.

- Cleaning: Regular cleaning of the chain is essential to remove dirt and debris that could cause damage. Utilize mild detergent and water, avoiding harsh chemicals that may corrode the stainless steel.

- Inspection: Conduct regular inspections for any signs of wear or damage. Replace any worn or damaged components promptly to prevent breakdowns and downtime.

Conclusion

The 08BHPFSS Stainless Steel Hollow Pin Chain is a reliable and versatile conveyor chain extensively used in numerous industrial applications. Its stainless steel composition, hollow pin design, impressive strength, low noise levels, and straightforward maintenance make it an outstanding option for situations requiring durability, adaptability, and dependability.

Choose Our Stainless Steel Roller Chains

RP Techniek BV serves as the official sales representative for Ever-power Group in the Netherlands. Our company is dedicated to providing high-quality products and exceptional customer service. Among our distinctive offerings is the 08BHPFSS Stainless Steel Hollow Pin Chain, which showcases our commitment to delivering dependable and long-lasting chains.

With advanced production facilities, we guarantee that each stainless steel roller chain adheres to the highest quality standards. Our chains are engineered to endure challenging conditions and ensure efficient power transmission. Additionally, we provide a broad selection of other stainless steel roller chains to meet diverse needs and applications.

At RP Techniek BV, we aim to surpass customer expectations with superior products and services. Whether you need stainless steel roller chains for industrial machinery, conveyors, or diverse applications, we have the ideal solution for you.

Sprockets for Sale

For those looking to find the perfect complement to the 08BHPFSS Stainless Steel Hollow Pin Chain, our extensive selection of sprockets is the answer. We offer a variety of sprockets designed to address your specific requirements.

Our sprockets are engineered with precision and durability in mind. Whether you require standard sprockets, double sprockets, or custom designs, we can fulfill your needs. Crafted from high-quality materials, our sprockets ensure lasting performance.

With our wide-ranging inventory, you can select from different sizes, tooth counts, and configurations to find the ideal match for your chain. We offer sprockets in various materials, including stainless steel, to guarantee optimal strength and corrosion resistance.

Understanding the necessity for reliability and efficiency in your machinery, we pride ourselves on providing a comprehensive range of sprockets that not only work seamlessly with the 08BHPFSS Stainless Steel Hollow Pin Chain but also enhance its performance.

Choose our sprockets for their superior quality, precise fitting, and competitive pricing. Trust us to deliver the appropriate sprockets to keep your operations running efficiently and smoothly.

Additional information

| Editor | Zqq |

|---|

Blogs Updated

The Structure and Design Features of Sprockets in Scraper Conveyors

This article mainly explains and analyzes the structural design characteristics of the sprocket based on its role in the scraper conveyor, thereby leading to the necessity of researching the material and processing technology of the sprocket and the key technical...

Scrapping and Replacement Standards for Chain Electric Hoist Lifting Sprockets

The scrapping and replacement standard of the lifting sprocket of the chain hoist is a very important safety issue. The lifting sprocket is an important component of the electric hoist. Once it becomes unusable, it must be replaced in a timely manner to ensure the...